Aluminum alloy heating method

An aluminum alloy and heating chamber technology, applied in the field of aluminum alloy heating, can solve the problems of inability to improve production efficiency, slow heating speed, and simple heating process, and achieve the effects of preventing heat loss, fast heating rate, and improving heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

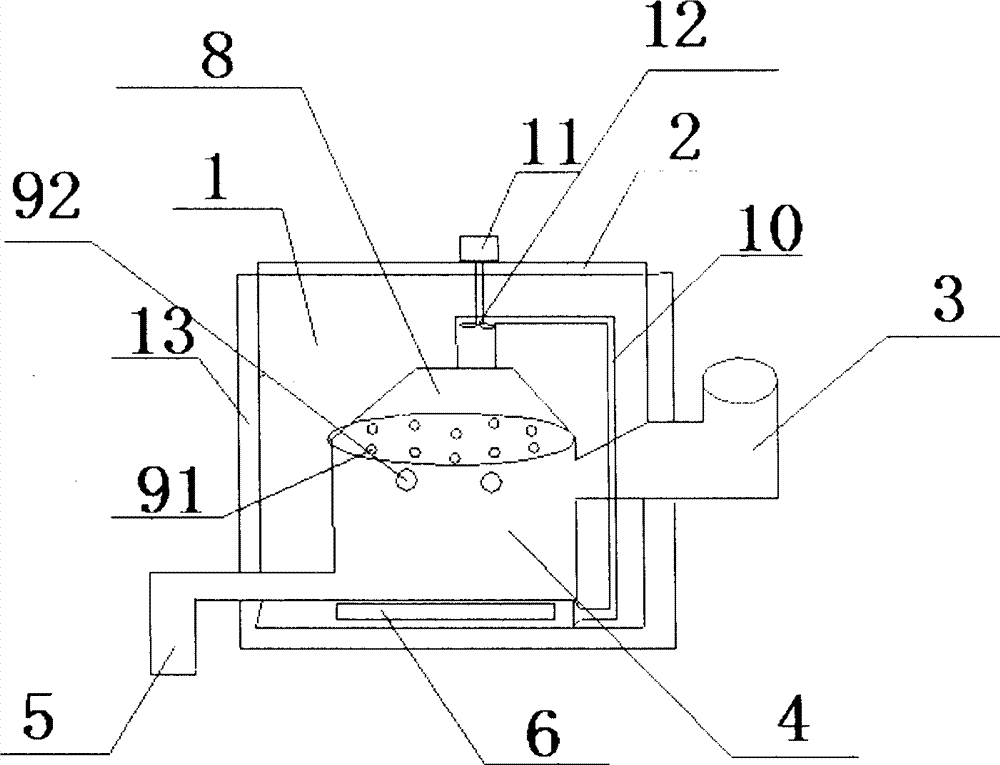

[0009] Such as figure 1 The aluminum alloy heating device includes a heating furnace 1 and a furnace cover 2. A heating chamber is arranged in the heating furnace 1. One side of the heating chamber 4 is connected with a feeding port 3 and the other side is connected with a discharging port 5. , can facilitate the operation of feeding and retrieving materials, the electric heating device 6 is provided under the heating chamber 4, and the heating chamber can be heated, and the heating pipe 7 with a diameter of 40mm-400mm is arranged in the heating chamber 4, The top of the heating chamber 4 is provided with an end cover 8, which is convenient for maintenance when an abnormal situation occurs in the heating chamber. The end cover 8 is provided with an air hole 91, which can allow hot air from the wind-heating pipeline to flow into the top of the heating chamber. The side of the heating chamber 4 near the position of the end cover 8 is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com