Multifunctional electrostatic spinning equipment

A technology of electrospinning and electrospinning, which is used in textiles and papermaking, spinneret assemblies, filament/thread forming, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

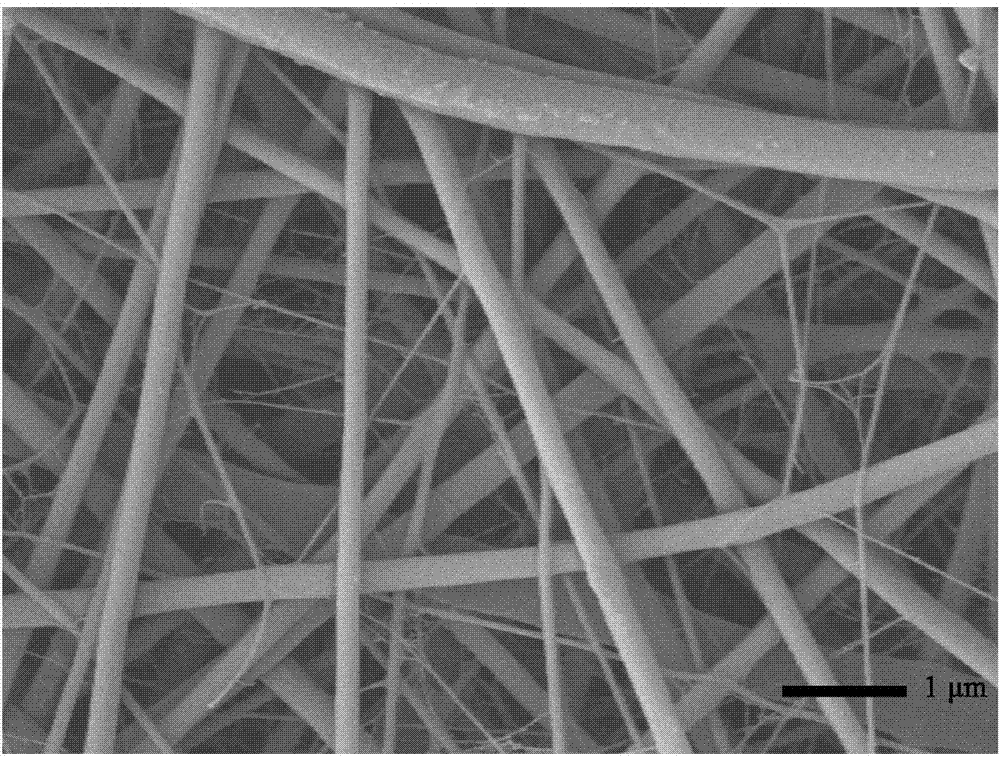

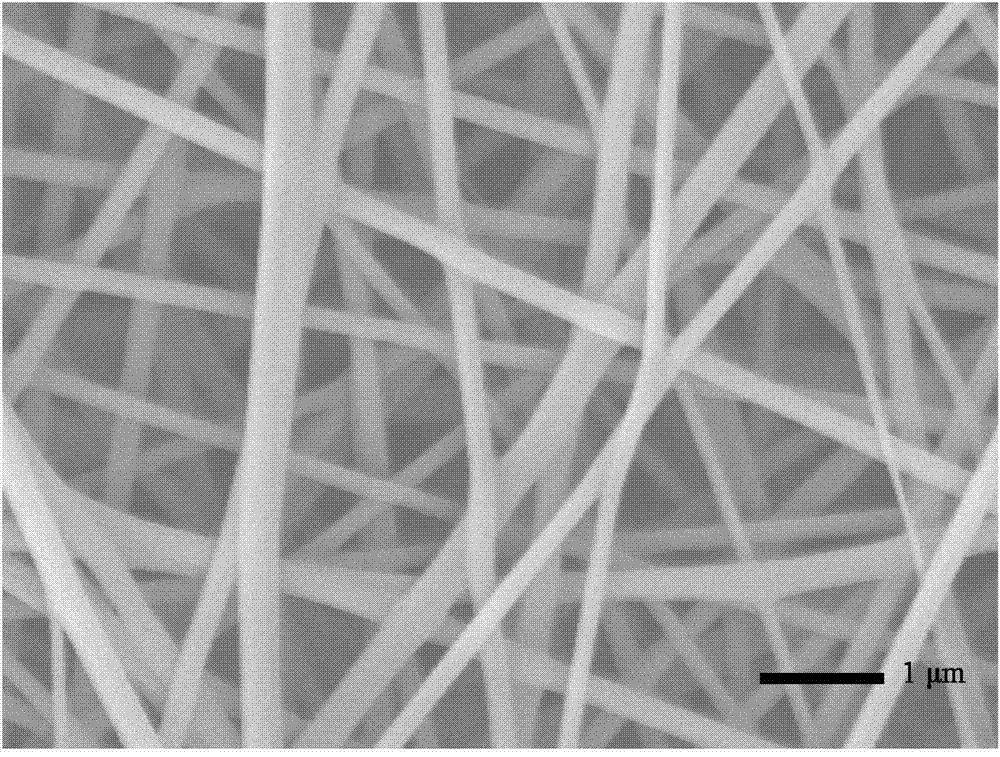

[0051] In order to explain the present invention more clearly, the following will briefly introduce some drawings. Obviously, the drawings listed below are only some embodiments of the present invention. Under the premise of labor, other drawings can also be obtained from these drawings.

[0052] The following will be combined with the Figure 4-Figure 9 , the present invention is described in more detail so that those skilled in the art can refer to and implement it.

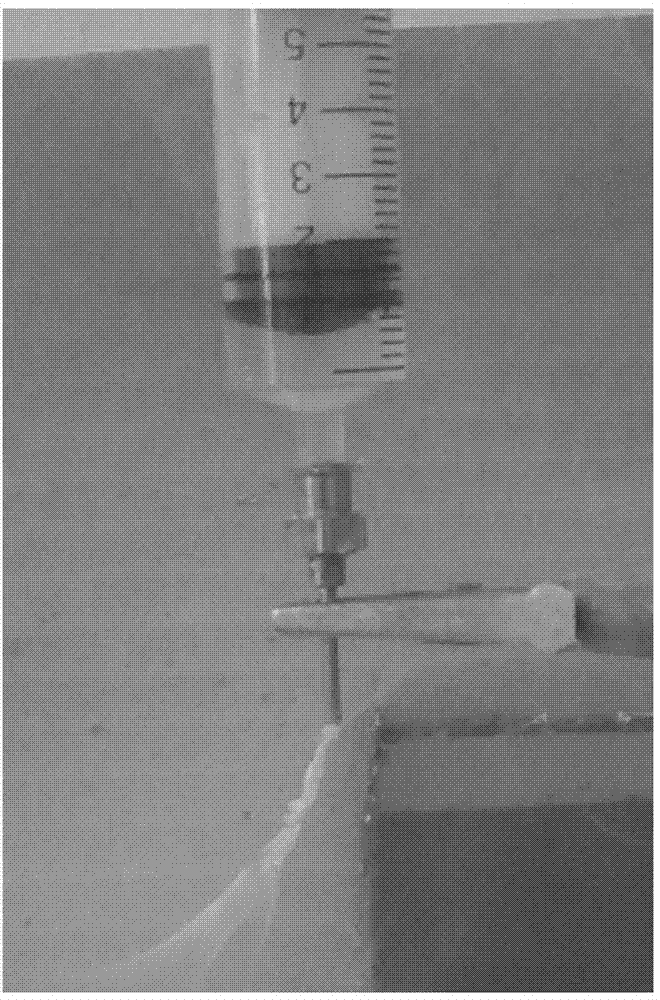

[0053] as attached Figure 4 As shown, the present invention— A multifunctional electrospinning device , including seven units: the electrospinning chamber (E1, E2 and E3), the pretreatment chamber P, the sampling chamber S, the inlet chamber C and the sample receiving chamber R, each unit is sealed in a glass cover 36; such as Figure 4 As shown, adjacent units are separated by partitions, and on the upper layer of the device, ie, above the horizontal partition 37, are three juxtaposed and mutually indepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com