A Solution Differential Electrospinning Nozzle

A differential electrospinning and nozzle technology, applied in the direction of spinneret assemblies, textiles and papermaking, filament/thread forming, etc., can solve the problem of low spinning output, achieve the effect of improving efficiency and solving low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

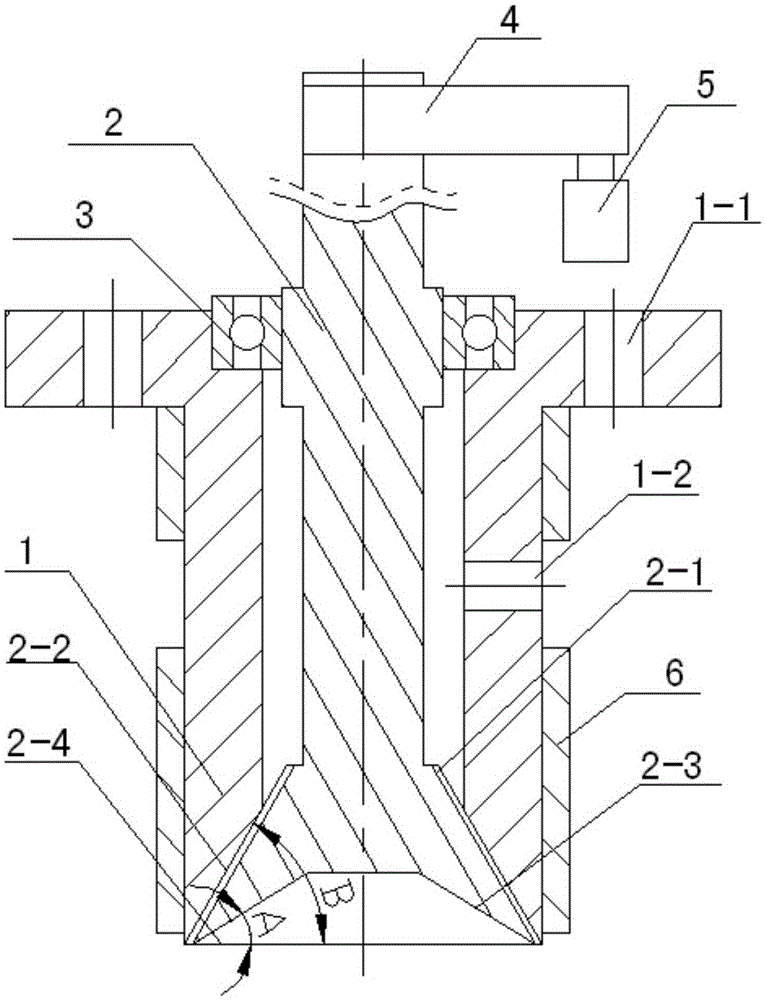

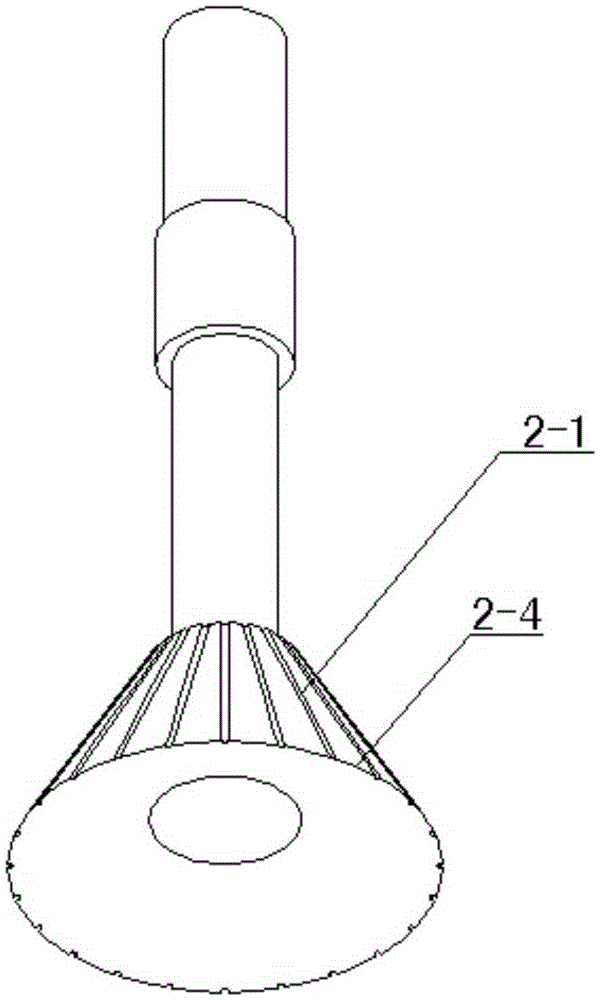

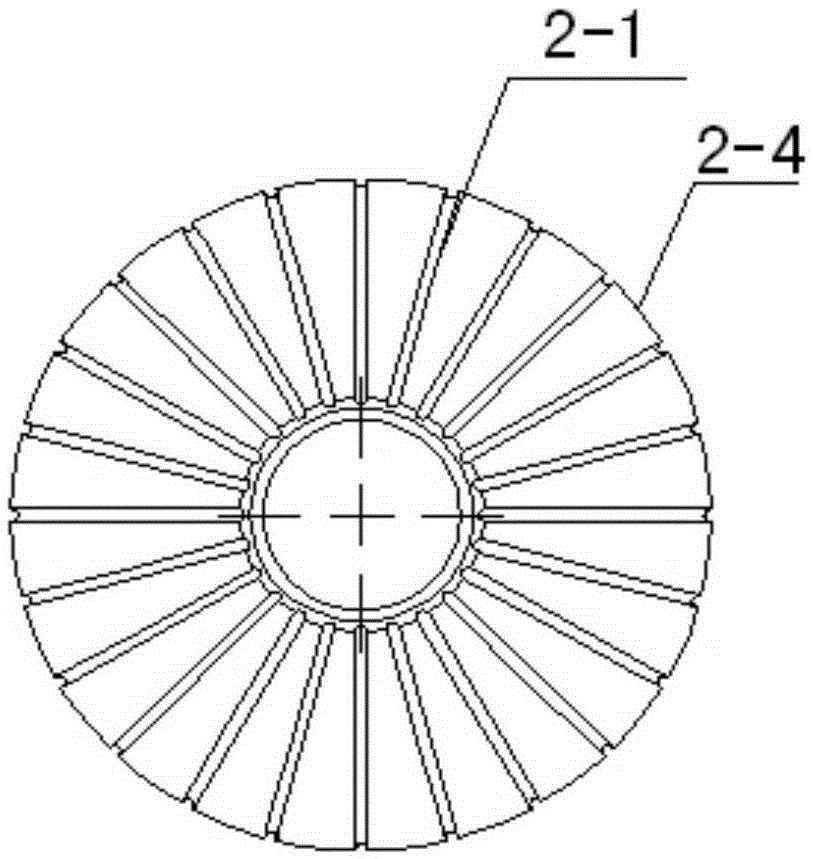

[0014] A solution differential electrospinning nozzle of the present invention, such as Figure 1~4 The schematic diagram shown mainly includes a nozzle sleeve 1 , a nozzle spindle 2 , a bearing 3 , a toothed belt 4 and a motor 5 . The nozzle main shaft 2 and the nozzle sleeve 1 are matched and sealed through the bearing 3. The nozzle main shaft 2 can be rotated and the position can be adjusted up and down. The upper end of the nozzle main shaft is connected with the motor 5 through the toothed belt 4. Rotation can be realized at the bottom. The toothed belt 4 is made of polymer materials such as nylon material, which can avoid the high-voltage electric breakdown of the nozzle. The nozzle sleeve 1 is fixed on the spinning frame through four bolt holes 1-1 evenly distributed on the upper end. , There are feeding ports 1-2 on the cylinder body. The lower part of the main shaft of the nozzle is a cone, and there are many evenly distributed micro-distributors 2-1 on the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com