A Microchannel Thermal Bubble Fuel Injection System

An injection system and channel technology, applied in fuel injection control, fuel injection device, charging system, etc., can solve the problems of complex overall structure, large mass, and large number of system components, and achieve small size, light weight, and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

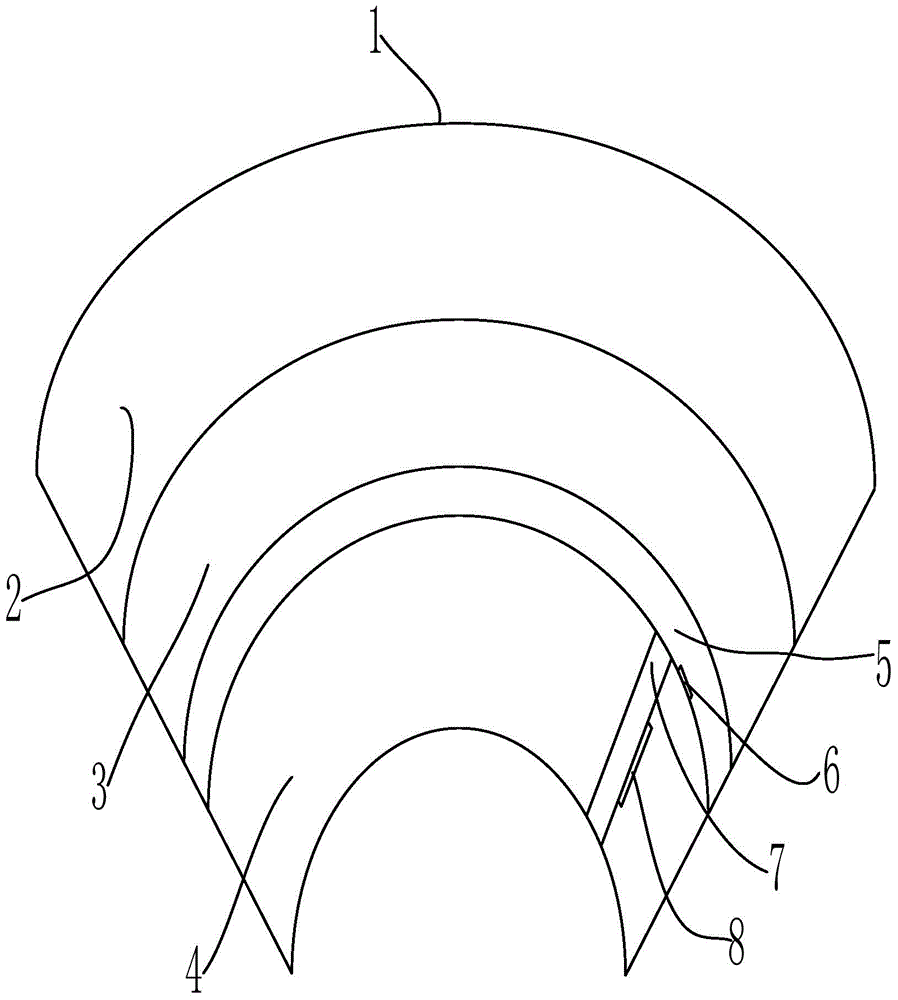

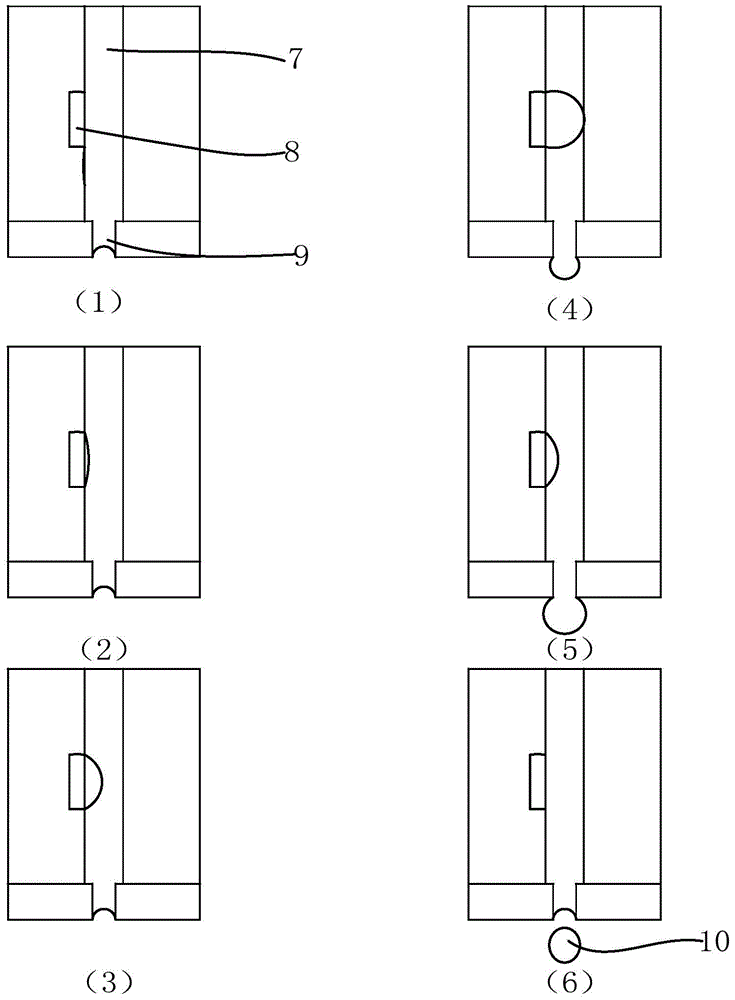

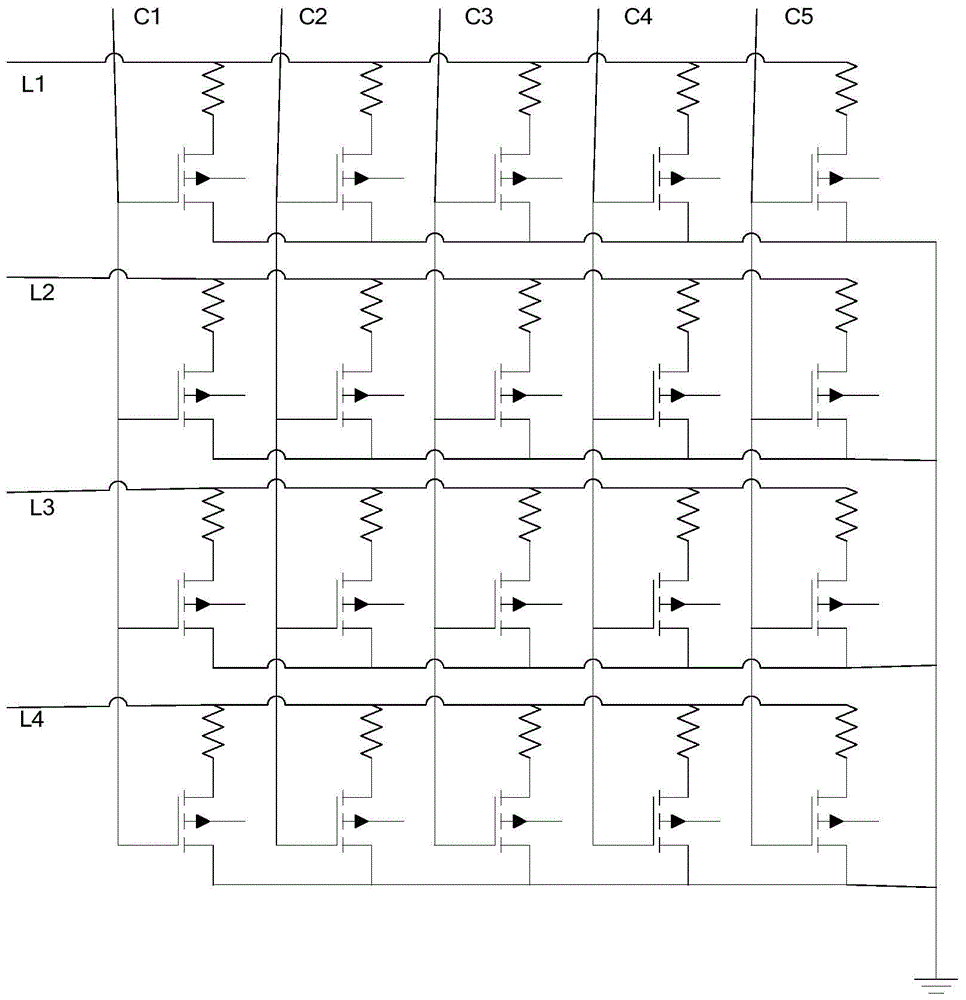

[0041] The invention provides a digital aviation piston engine fuel atomization injection system, such as figure 1 As shown, it includes housing 1, external socket 2, decoder 3, fuel injection nozzle placement chamber 4, internal oil supply channel 5, oil supply channel temperature sensor 6, thermal bubble channel 7, heating resistor 8, and fuel injection nozzle 9.

[0042] The overall shape of the housing 1 is arc-shaped, and it is divided into three parts from the outside to the inside. The outermost part is the external socket 2, which is the channel connecting the fuel atomization system with the engine ECU, and is responsible for receiving the input signal of the decoder 2. , and at the same time transmit the oil temperature signal of the oil supply channel temperature sensor to the engine ECU. The middle part is a circuit decoder 3 and an internal oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com