Method and device for measuring flow of multi-component gas

A flow measurement device and flow measurement technology, which are applied in the direction of mass flow measurement device, measurement device, liquid/fluid solid measurement, etc., can solve problems such as poor measurement accuracy, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

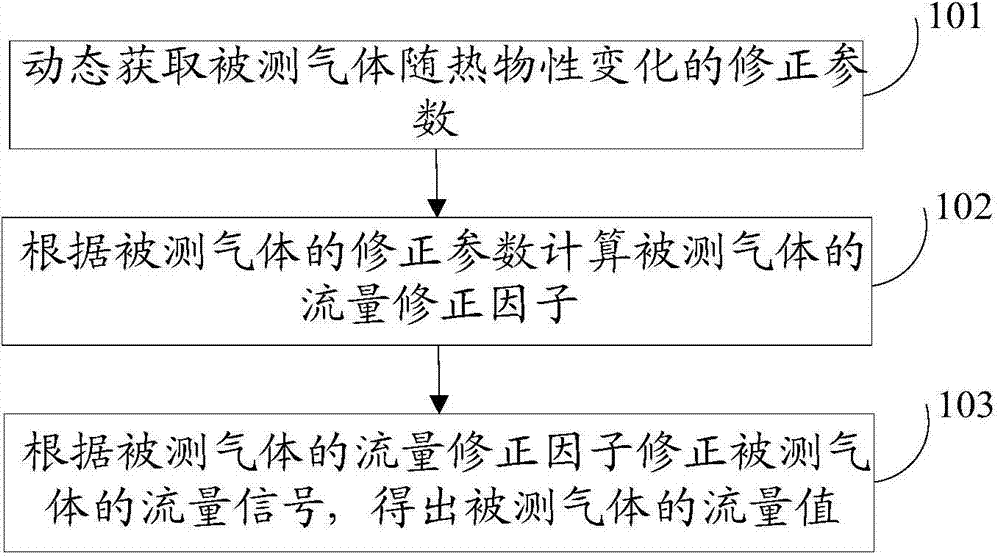

[0031] Embodiments of the present invention provide a flow measurement method for multi-component gas, such as figure 1 As shown, the method includes:

[0032] 101. Dynamically obtain the correction parameters of the measured gas changing with the thermal physical properties.

[0033] For example, dynamically obtaining the correction parameters of the measured gas with the change of thermal physical properties includes: monitoring the change of the physical properties of the measured gas, and obtaining the current correction parameters of the measured gas when the physical properties of the measured gas change; or, obtaining according to a preset cycle The correction parameters of the measured gas change with the thermal physical properties, the preset period is a fixed period or set according to the composition change of the measured gas; or, if the flow correction factor calculated in the current period is the same as the flow correction factor calculated in the previous per...

Embodiment 2

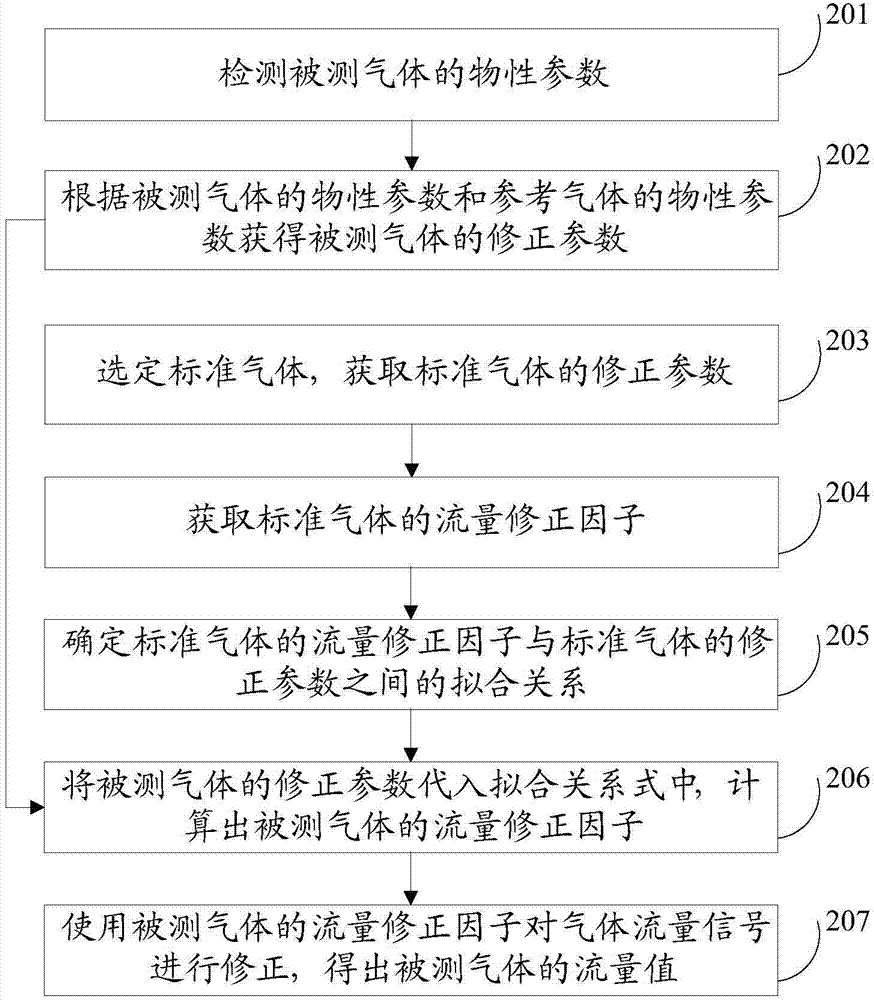

[0043] An embodiment of the present invention provides a method for measuring the flow rate of a multi-component gas. The gas to be measured is a mixed gas composed of any components, such as figure 2 As shown, the method includes:

[0044] 201. Detect the physical parameters of the gas to be measured.

[0045] For example, real-time monitoring of physical properties such as thermal conductivity, working-condition heat capacity, and thermal diffusivity of the measured gas under actual working conditions through physical property sensors, to obtain the measured gas thermal conductivity λ, working-condition heat capacity ρC p And physical parameters such as thermal diffusivity α.

[0046] Preferably, a MEMS (Micro-Electro-Mechanical System, Micro-Electro-Mechanical System) calorimetric property sensor is used to monitor the physical properties of the measured gas, and the MEMS calorimetric property sensor can realize simultaneous detection of multiple physical properties and f...

Embodiment 3

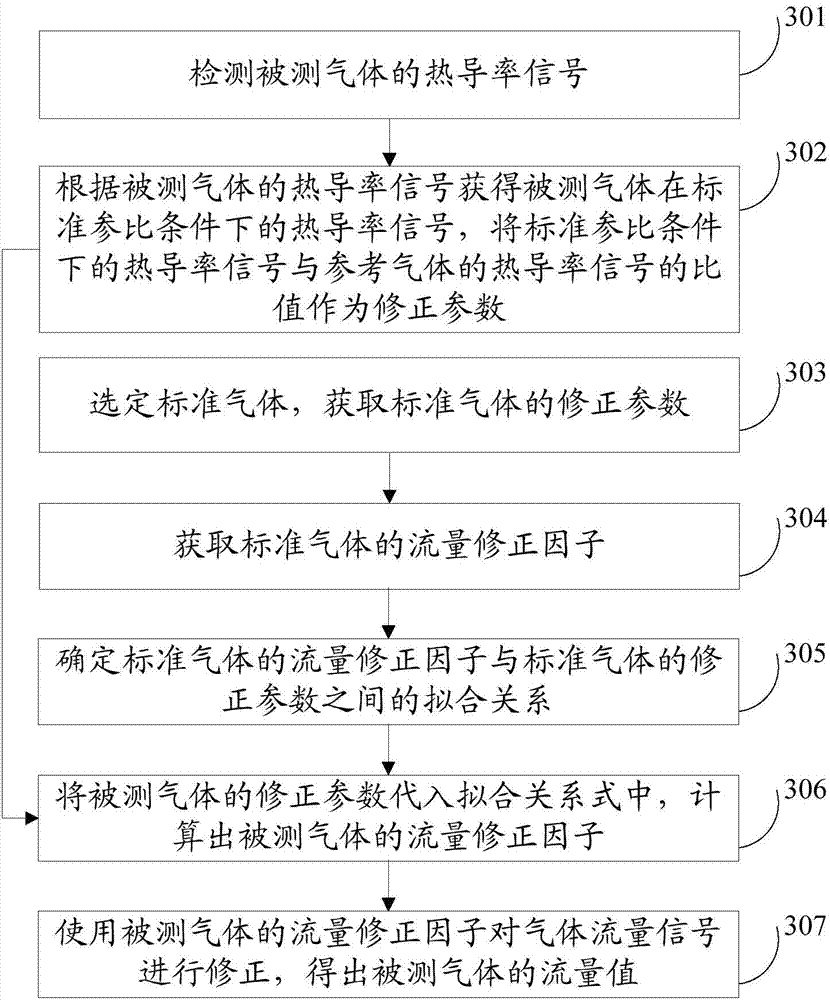

[0085] The embodiment of the present invention provides a method for measuring the flow rate of multi-component gas. The measured gas is preferably natural gas or a mixed gas within the range of natural gas components, such as image 3 As shown, the method includes:

[0086] 301. Detect a thermal conductivity signal of the gas to be measured.

[0087] For example, real-time monitoring of thermal conductivity changes of the measured gas due to components or environmental factors through the thermal conductivity sensor, to obtain the thermal conductivity signal λ of the measured gas 1 ; Detect the temperature T of the gas to be measured through the ambient temperature temperature measuring element on the flow sensor, and detect the pressure P of the gas through the pressure sensor module.

[0088] Preferably, the MEMS calorimetric physical property sensor is used to monitor the thermal conductivity signal of the measured gas, and the MEMS calorimetric physical property sensor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com