Clamping piece polishing device

A technology of clips and grinding surfaces, applied in the field of clip performance testing, can solve problems such as smaller than true values, inaccurate test results, and large differences in hardness values, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

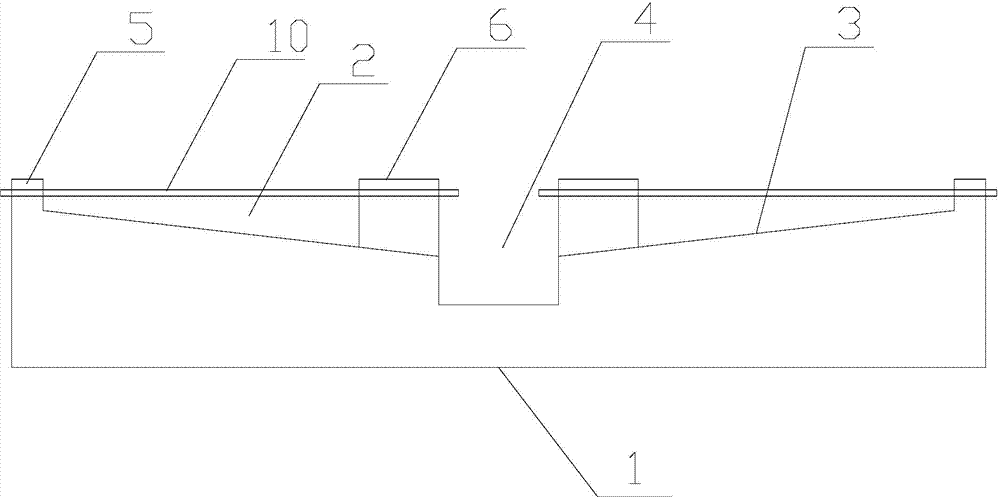

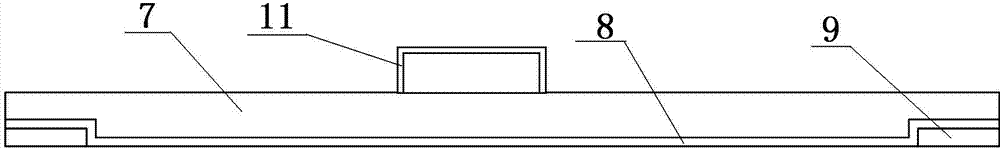

[0017] A handle 11 is also provided at the top center of the cover body 7 .

[0018] The blocking piece, the large groove, the small groove and the slope are designed in one piece, and the height of the blocking piece is lower than that of the clip after the clip is installed. The setting of the small groove makes the clip positioning bar 6 have a certain space for movement.

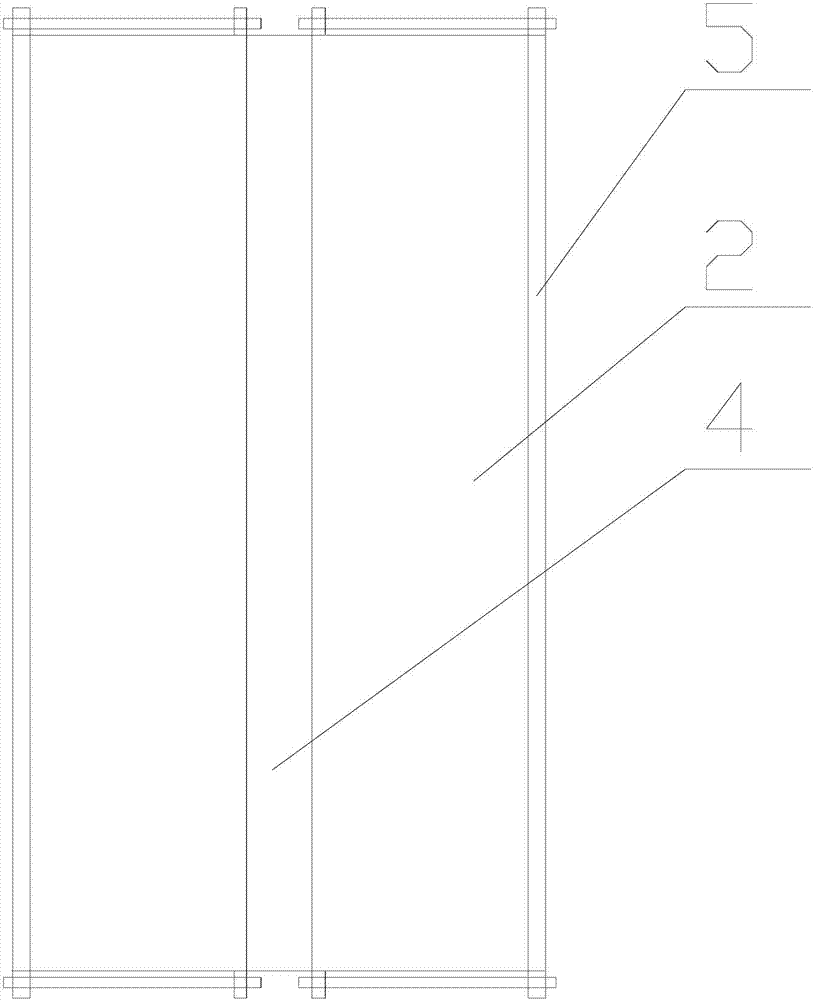

[0019] The cover plate body 7 is a rectangular plate body, and a set of long side edges on the surface where the sandpaper is installed is provided with an installation groove matched with the sandpaper positioning strips to form a smooth grinding surface after the sandpaper and the sandpaper positioning strips are installed.

[0020] There are four screw rods, which are respectively located at the two ends of the positioning bar 6 and the blocking piece 5 .

[0021] When in use, the clips 12 are first installed on the slope of the large groove in sequence, then clamped and fixed by the baffle, the clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com