Optical module

An optical module, the first technology, applied in the field of optical modules, can solve the problem that the operating temperature of the optical module cannot meet the industrial-grade operating temperature range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

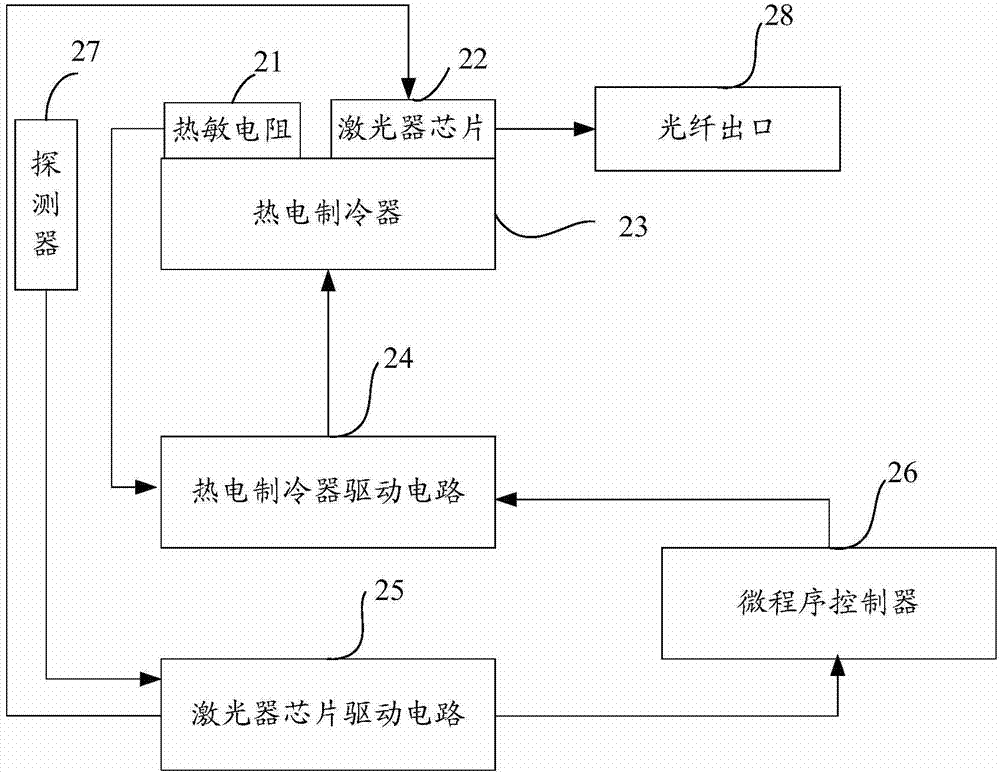

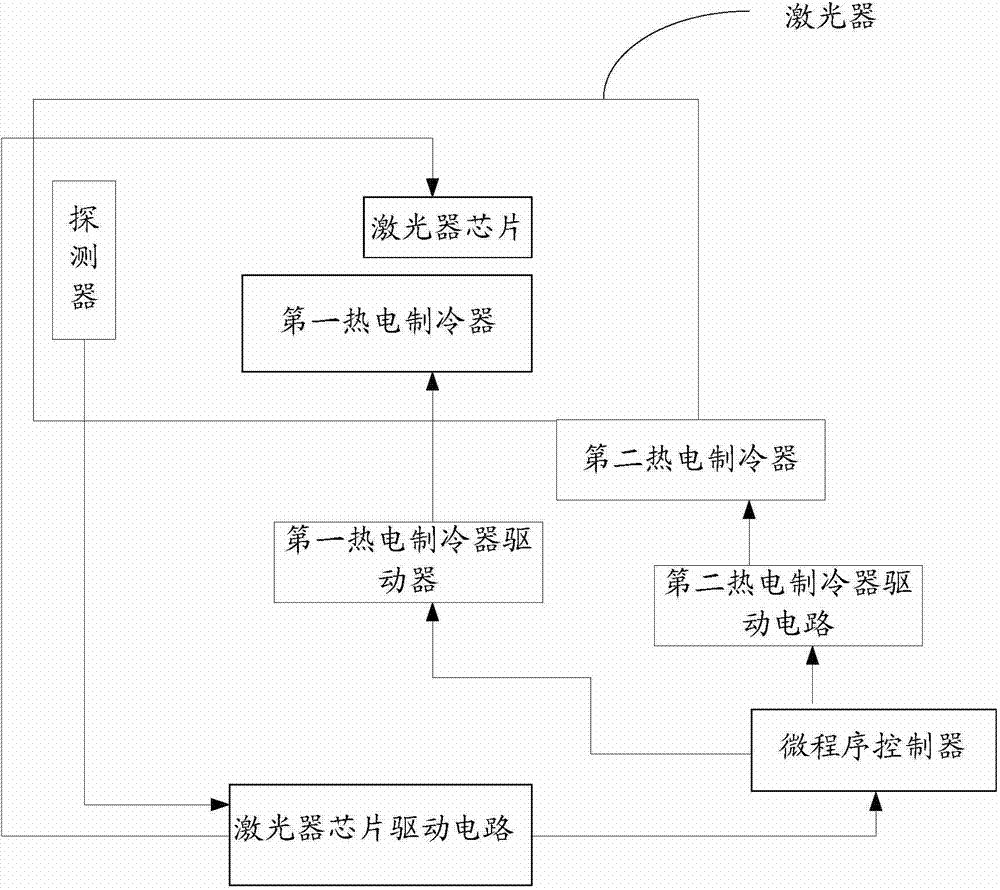

[0022] The optical module in the embodiment of the present invention includes a first thermoelectric cooling TEC, the first TEC is arranged inside the laser, and the first TEC is used for heating or cooling according to the input start signal of the microprogram controller MCU; the first Two TECs, the second TEC is arranged on the shell of the laser, and the second TEC is used for heating or cooling according to the MCU input start signal; The magnitude of the operating current input by the chip determines whether to input the on or off signal to the first TEC and the second TEC. In the above-mentioned embodiment, the first TEC is arranged inside the laser, and the second TEC is arranged on the laser shell. The first TEC and the second TEC can perform heating or cooling operations according to the start signal input by the MUC, wherein the MCU drives the circuit according to the laser chip. The magnitude of the working current input to the laser chip controls the working state...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap