Method for laser engraving of nasal prosthesis

A laser engraving and nasal prosthesis technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of nasal prosthesis falling off, poor fit of nasal prosthesis, affecting postoperative recovery, etc., to achieve easy recovery and improve fit The effect of reducing the difficulty of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Choose laser equipment with power of 30W-60W, engraving speed of 100mm / s-500mm / s, point spacing of 0.08mm-0.15mm, and one layer cutting can reduce the thickness of 0.1mm-0.3mm.

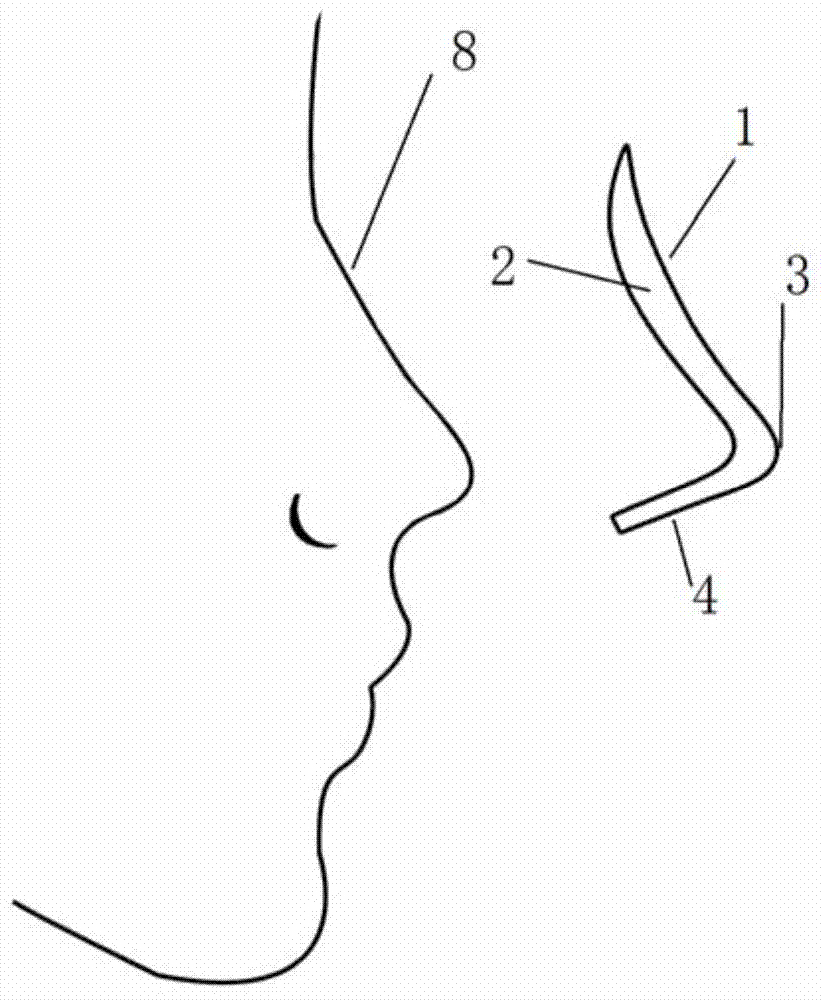

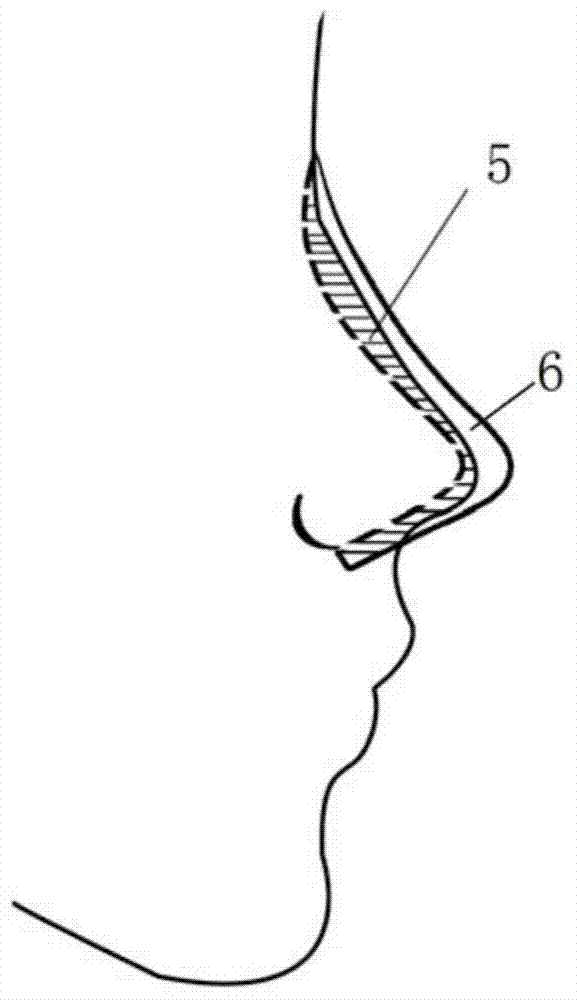

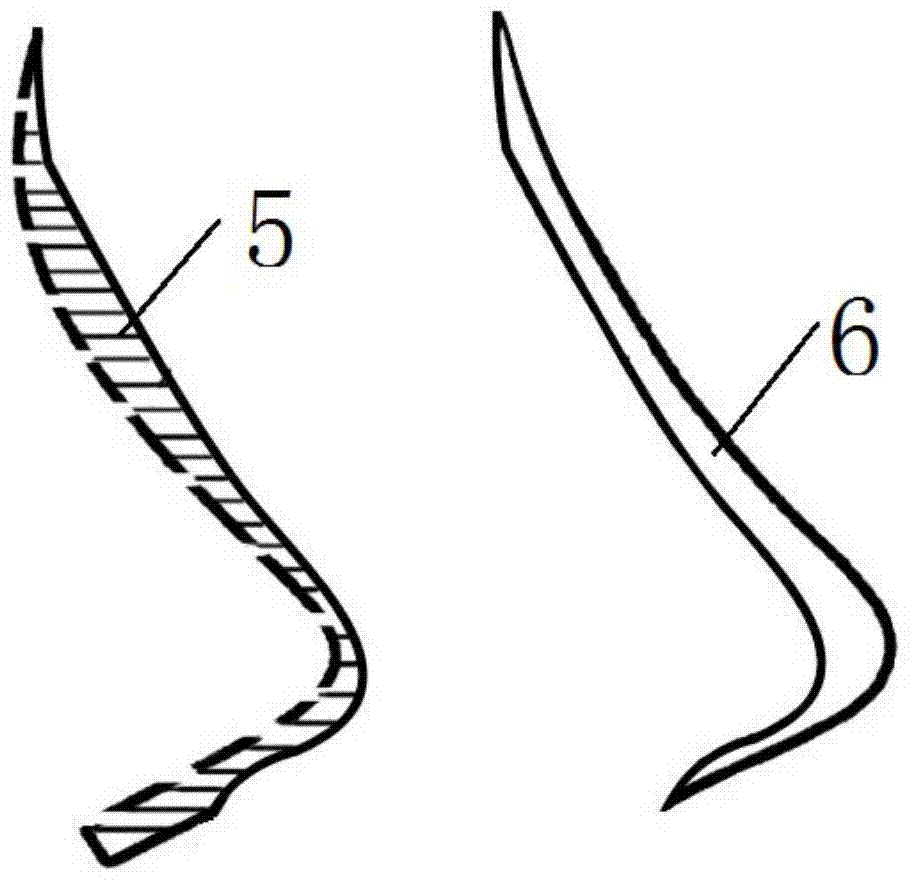

[0046] Such as figure 1 As shown, the three-dimensional simulation display of nasal prosthesis 1 and nose 8, such as figure 2 As shown, the three-dimensional simulated nasal prosthesis overlaps with the nose, and the nasal prosthesis is divided into a layered part 5 that needs to be removed and a reserved part 6 that needs to be retained, as shown in image 3 As shown, the separate 3D simulation data of the delaminated part 5 and the reserved part 6.

[0047] Such as Figure 4 As shown, adjust the best laser focus distance of the equipment, set the corresponding energy parameters, and fix the nasal prosthesis 1 with a fixture. The silicone material is quite special, so it must be fixed with a fixture to prevent the nasal prosthesis from shaking, which will affect the carving work. Then imp...

Embodiment 2

[0055] Using the laser layer cutting and engraving method of Embodiment 1, the step S3 further includes: cleaning the residual substances on the surface of the nasal prosthesis with an air supply device after removing one processing layer. During the layer cutting process, dust and other impurities will be generated, and dust and other impurities will stick to the surface of the product. If it is not cleaned in time, the accuracy of layer cutting will be affected. After layer cutting, use the air supply equipment to blow and clean it once to remove dust, etc. The effect of impurities on layer cutting of laser equipment.

Embodiment 3

[0057] Using the laser layer cutting engraving method of Embodiment 1, when the laser equipment cuts the nasal prosthesis, the nasal prosthesis is placed in a nitrogen environment for layer cutting. The nasal prosthesis is placed in a nitrogen environment. During the layer cutting process, the surface temperature of the silicone prosthesis is changed through the particularity of nitrogen, and the silicone prosthesis product will not be burned due to long-term high temperature, which will affect the quality of the prosthesis itself. , and the nitrogen is relatively stable, which can prevent the characteristics of the nasal prosthesis from changing under high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com