a fire extinguishing device

A technology of fire extinguishing device and fire extinguishing agent, which is applied in the direction of fire rescue, etc., can solve the problems of high production cost of fire extinguishing device, difficulty in general use of main accessories of fire extinguishing products, difficulty in mass production of accessories, and mechanized production, so as to achieve better fire extinguishing effect and convenient Batch production, the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

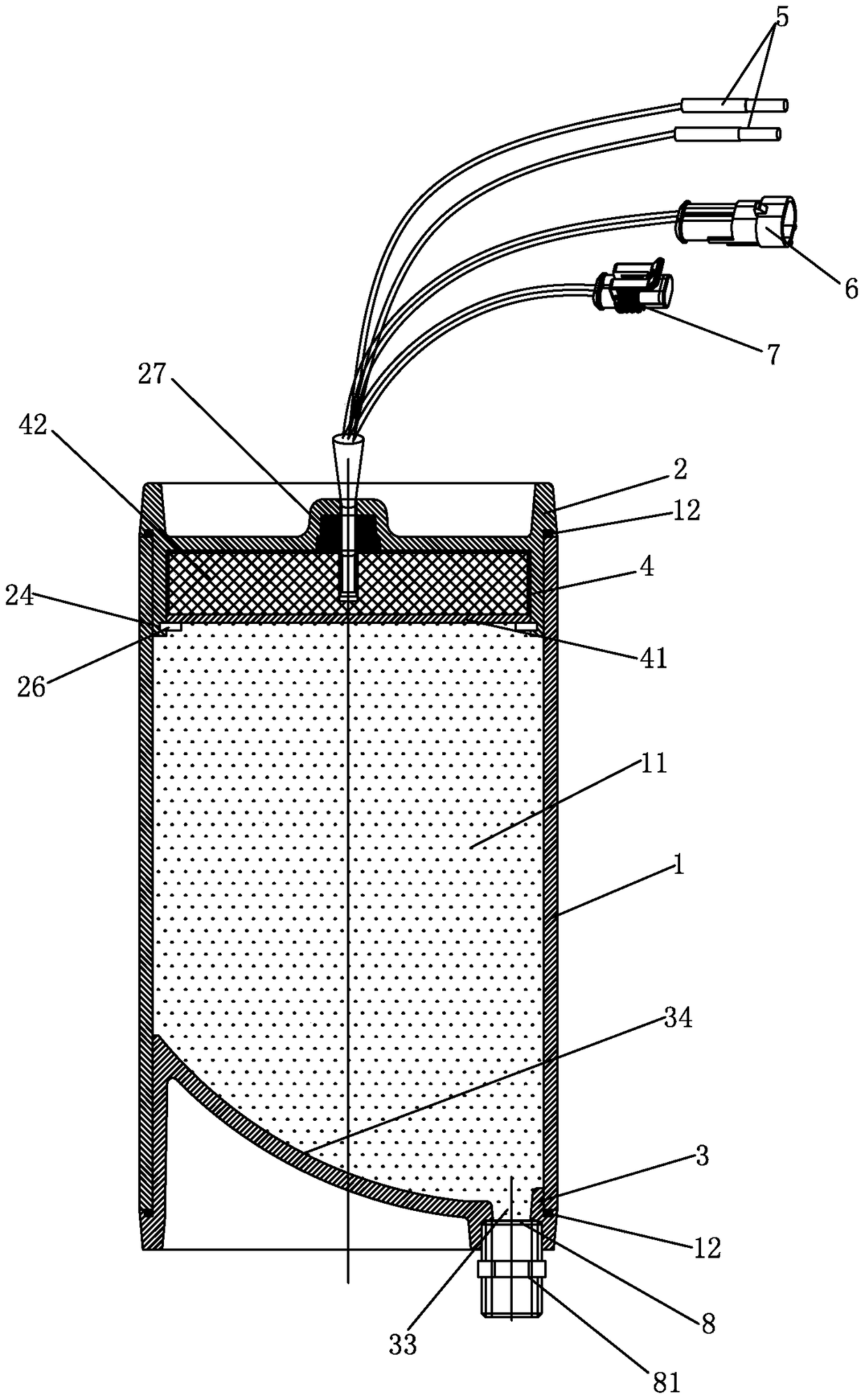

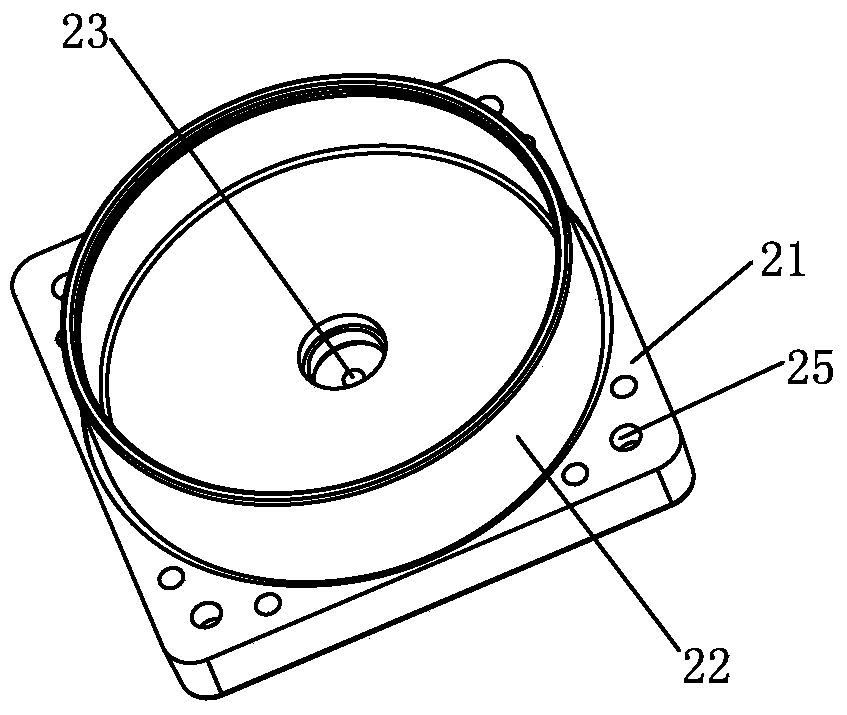

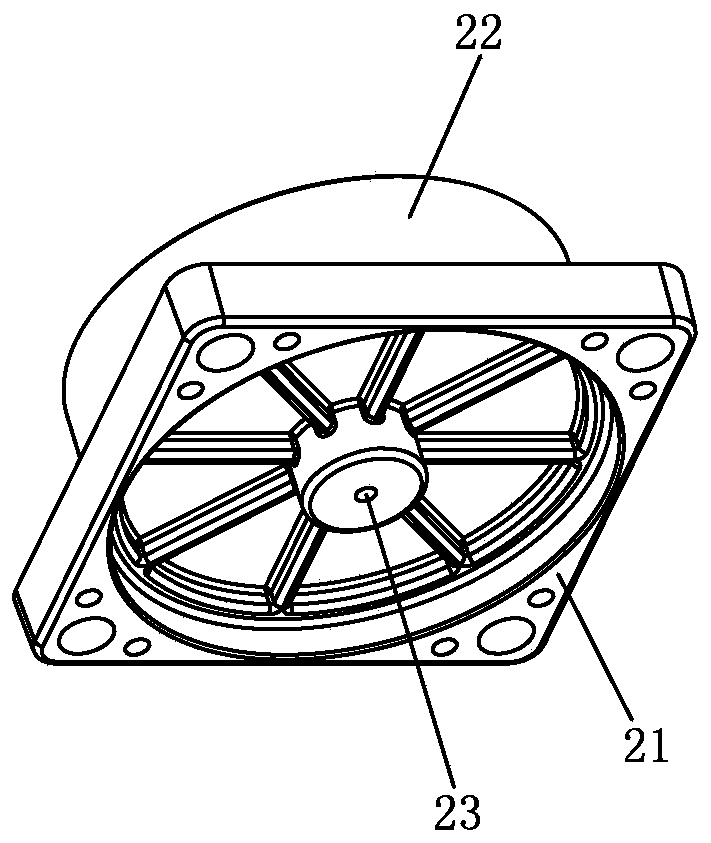

[0048] See Figure 1-Figure 5 As shown, a fire extinguishing device of the present invention, the shell of the fire extinguishing device includes a cylinder body 1 , a first end cover 2 and a second end cover 3 that are open at both ends and are not deformed or cracked when activated. Wherein, cylinder body 1 adopts stainless steel pipe or cold-drawn cold extruded aluminum alloy pipe, and the cross-sectional shape of the periphery of this cylinder body 1 is rectangle (such as figure 2 As shown, this is a cold-drawn and cold-extruded aluminum alloy tube; or, the cross-sectional shape of the outer circumference of the cylinder 1 can also be circular, oval, etc.), and the cross-sectional shape of the inner circumference is circular. The first end cover 2 and the second end cover 3 are produced by moulds, which have good consistency and stability in performance and size. The first end cover 2 is sealingly connected to the opening at one end of the cylinder body 1, and the second...

Embodiment 2

[0063] See Figure 19 As shown, a fire extinguishing device of the present invention differs from Embodiment 1 in that the fire extinguishing agent nozzle 33 of the second end cover 3 is located at the center of the second connection seat 31, and the guide portion 32 on the The guide surface 34 is in the shape of a spherical crown.

Embodiment 3

[0065] See Figure 20 As shown, a fire extinguishing device of the present invention differs from Embodiment 1 in that the outer diameter of the annular side wall 22 of the first end cover 2 is smaller than the inner diameter of the cylinder 1, that is, when the first end cover 2 is sealed When connected to the cylinder 1 , the outer peripheral side of the annular side wall 22 is not in close contact with the inner wall of the cylinder 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com