Supporting device for torpedo type iron mixing car tank

A supporting device and a technology of a mixed iron car, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of high manufacturing cost of sliding bearing wear, double rolling bearing, low efficiency of double sliding bearing, and difficulty in installation and maintenance. Achieve the effects of small friction coefficient, safe and reliable use, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

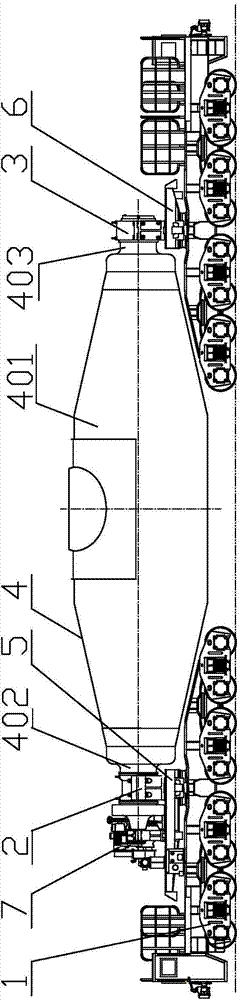

[0024] like Figure 1-Figure 3 As shown in the figure, a torpedo-type mixed iron car tank body support device includes a running device 1, a tank body support device I 2, a tank body support device II 3 and a tank body device 4, and the running device 1 is provided with a driving end bearing Stand 5 and driven end bearing stand 6, said driving end bearing stand 5 is provided with a tilting device 7,

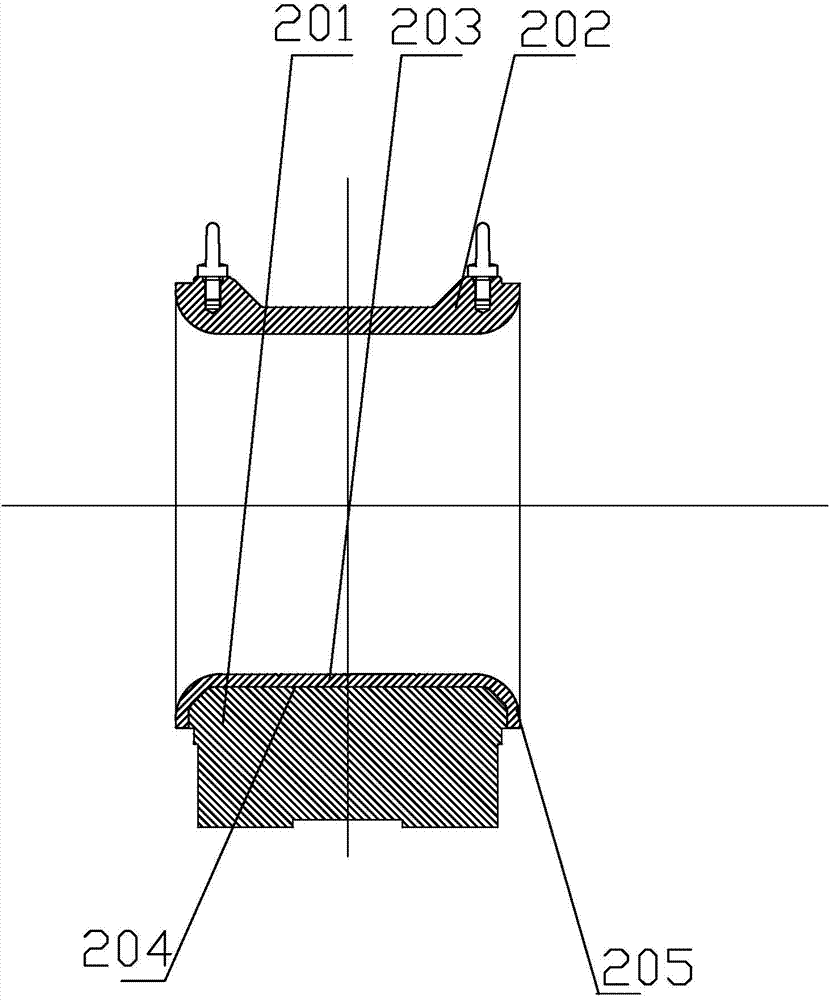

[0025] The tank supporting device I 2 includes a driving end bearing seat 201, a driving end bearing cover 202 and a semi-cylindrical sliding bearing 203, the outer wall of the semi-cylindrical sliding bearing 203 is connected to the mounting part 204 of the driving end bearing seat 201 matched and fixedly connected, the active end bearing housing 201 is fixedly connected to the active end bearing stand 5,

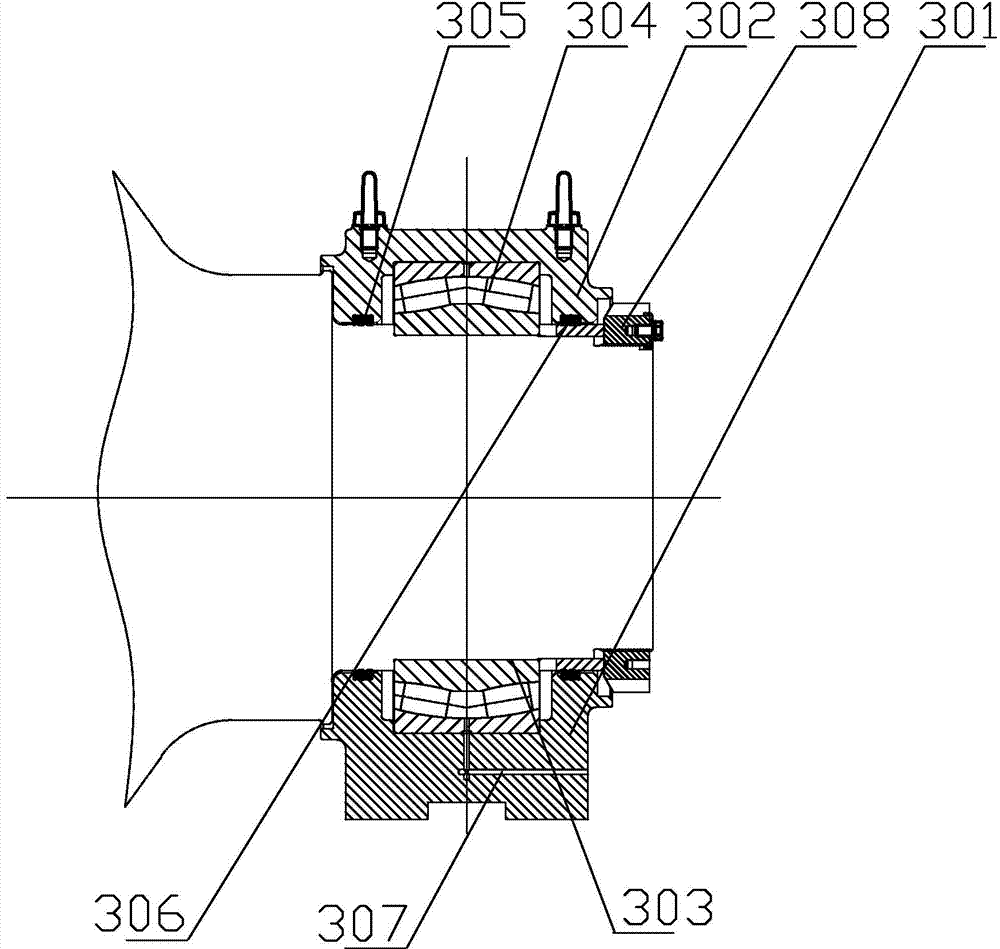

[0026] The tank supporting device II 3 includes a driven end bearing seat 301, a driven end bearing cover 302 and a rolling bearing located in the installation hole 303 surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com