Cutting edge grinding mechanism for automatic grinding device of surgical blade cutting edge and grinding device

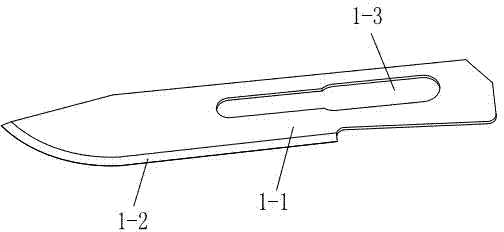

A surgical blade and cutting edge technology, which is applied in the field of automated machinery and equipment, can solve the problems of not being able to meet the sharpness of the surgical blade, uneven sharpness of blade 1-2, low work efficiency, etc., and meet the requirements of high sharpness and sharpness. The effect of uniformity and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

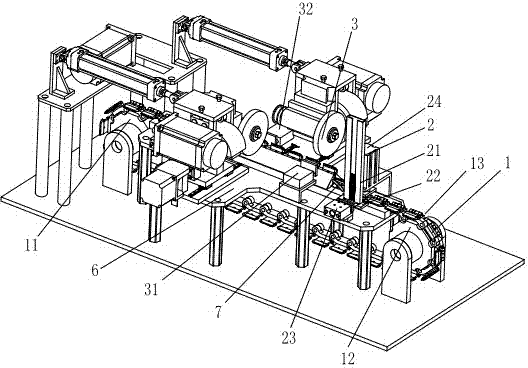

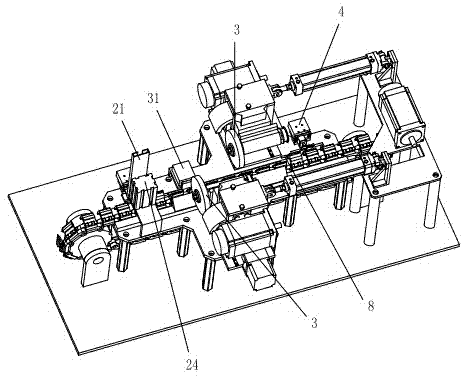

[0052] Such as figure 2 , image 3Shown, the automatic grinding device of surgical blade cutting edge of the present invention comprises chain conveying mechanism 1, and chain conveying mechanism 1 comprises driving sprocket 11, driven sprocket 12 and walks around driving sprocket 11 and driven sprocket 12 The chain 13 and the driving sprocket 11 can drive the chain 13 to run (running from right to left in the figure) driven by the chain drive motor; each link of the chain 13 is connected to a clamp 5 respectively, and the clamp 5 is used for clamping The surgical blade workpiece; the clamp 5 is hinged with the chain link of the chain 13, and the clamp 5 can rotate around the chain link, thereby switching between the horizontal state and the vertical state; the clamp 5 is also provided with a return spring parallel to the chain;

[0053] The blade loading station, the first sharpening station, the second sharpening station, and the unloading station are sequentially formed a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap