Waste cotton cleaning system based on non-impact reversing mechanism

A technology of reversing mechanism and cleaning system, applied in the field of textile manufacturing, can solve the problems of large impact of cleaning device, high rated power of motor, easy damage of dragon belt, etc., and achieve the effect of reducing damage, reducing requirements and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

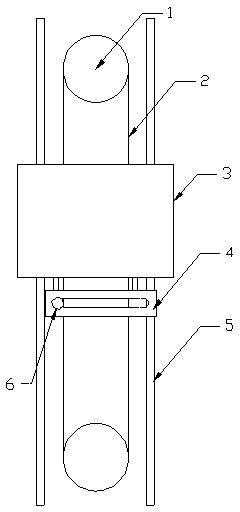

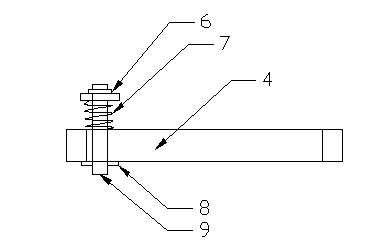

[0022] Such as figure 1 It can be known from the schematic diagram that the waste cotton cleaning system based on the non-impact reversing mechanism of the present invention includes a frame, a cleaning device 3, a non-impact reversing mechanism and a driving mechanism.

[0023] The cleaning device 3 is installed on the frame of the textile equipment through the guide rail 5, and is driven by the cleaning driving mechanism to perform blowing and suction cleaning. In this embodiment, the textile equipment may be related machinery such as spinning frames, roving frames, textile machines, and looms.

[0024] The cleaning driving mechanism is a fan motor, which is installed on the upper end of the cleaning device. In this embodiment, installing the fan motor on the upper end of the cleaning device can reduce the space required by the cleaning device 3 as a whole.

[0025] The cleaning device 3 can be driven by a displacement drive mechanism to move directly along the extending d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com