Spliced large-diameter steel corrugated pipe construction method

A construction method and corrugated pipe technology, which is applied in the construction field of large-diameter steel corrugated pipes in bulk, can solve the problems of long construction time of corrugated pipes, poor foundation treatment, and easy cracking of pipe joints, etc., so as to facilitate product quality control and save costs , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

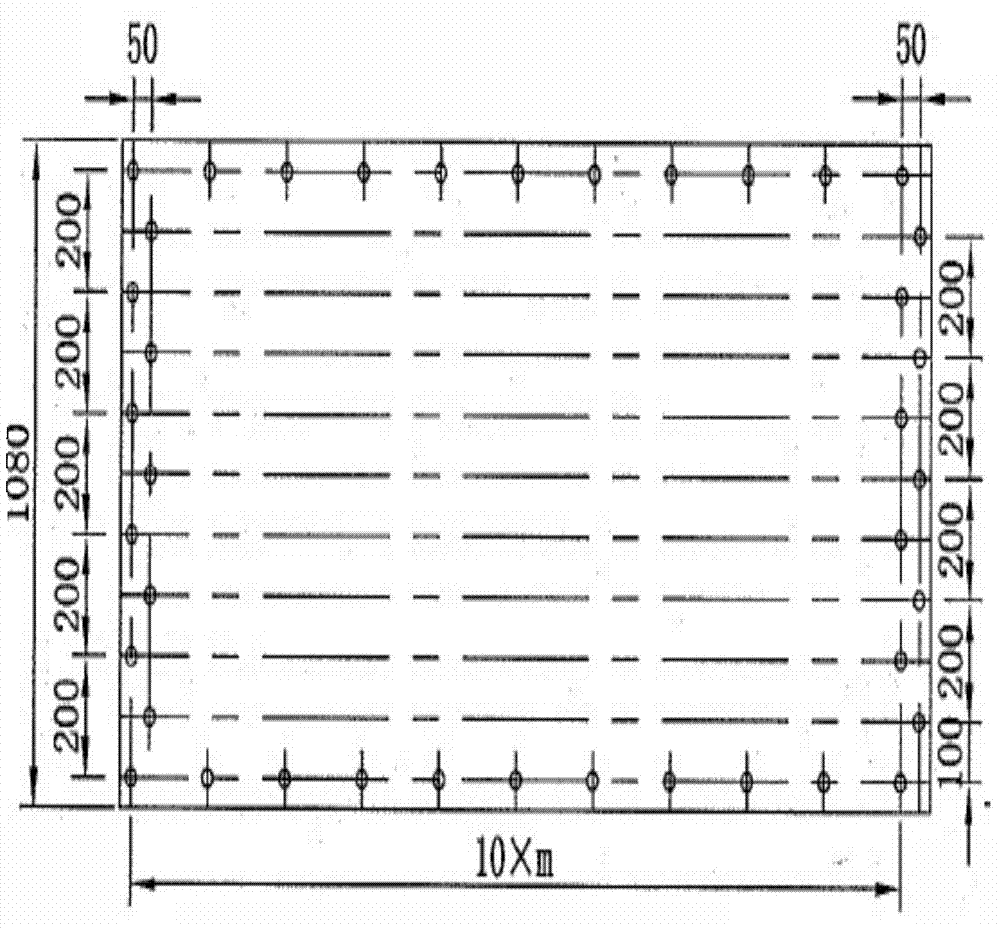

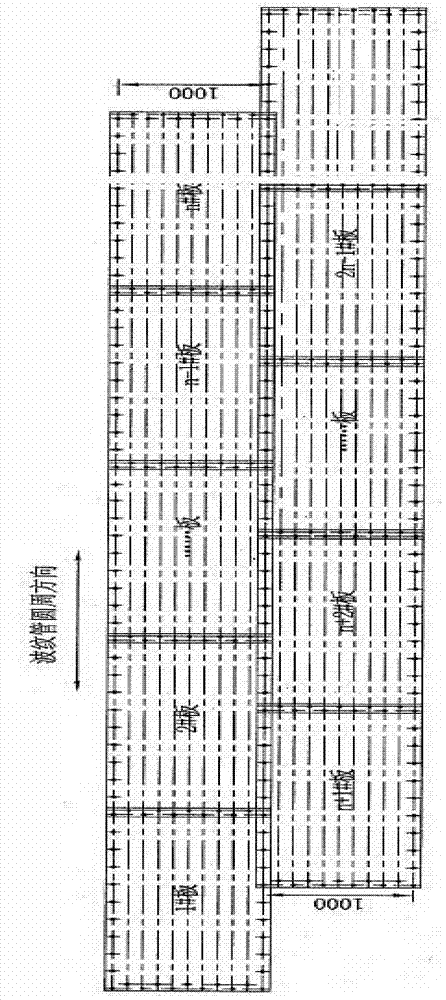

[0026] The construction process of bulk large-diameter steel bellows includes the following steps: foundation pit excavation, site leveling, foundation construction, pre-camber setting, steel bellows assembly, steel bellows joint deviation correction, joint fixation, sealant Treatment, asphalt waterproof layer treatment, backfilling of platform back and eight-character wall construction;

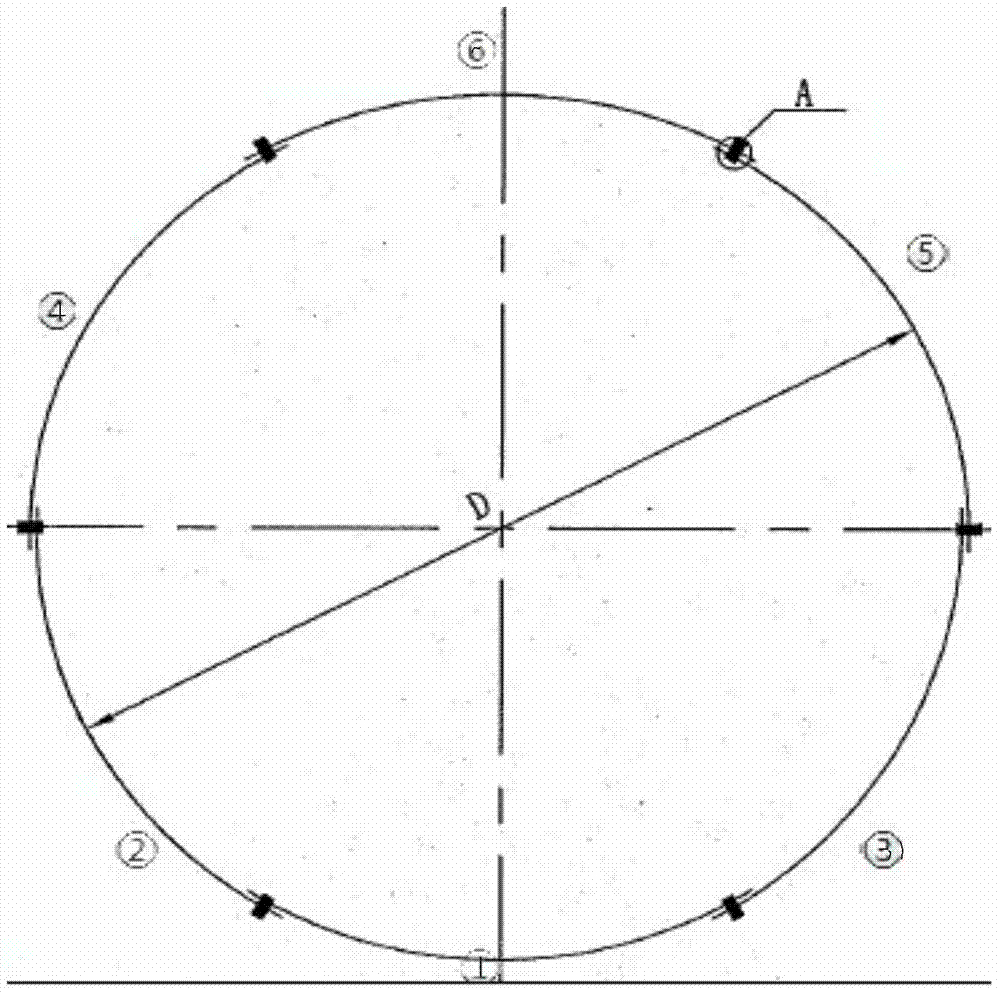

[0027] 1. Measurement and stakeout

[0028] Before pipe culvert construction, the center and vertical and horizontal axes of the pipe culvert should be accurately determined first. And do a good job of pile protection, foundation pit slope slope according to 1:1 for grading.

[0029] 2. Foundation pit excavation

[0030] The method of manual and mechanical excavation is adopted, and the slope of the foundation pit side slope is graded according to 1:1. For places with deep excavation depth and water, the stable side slope should be the main method, and the slope should be properly graded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com