Novel ceiling lamp chassis

A ceiling lamp and chassis technology, applied in lighting devices, light sources, fixed lighting devices, etc., can solve the problems of non-uniform specifications of LED lamp bead strips or lamp bead rings, difficulty in replacing ordinary users, and restricting the promotion of lighting products. It is difficult to replace, eliminates light and dark areas, and replaces easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] detailed description, Embodiments of the present invention are further elaborated below in conjunction with accompanying drawings:

Embodiment approach 1

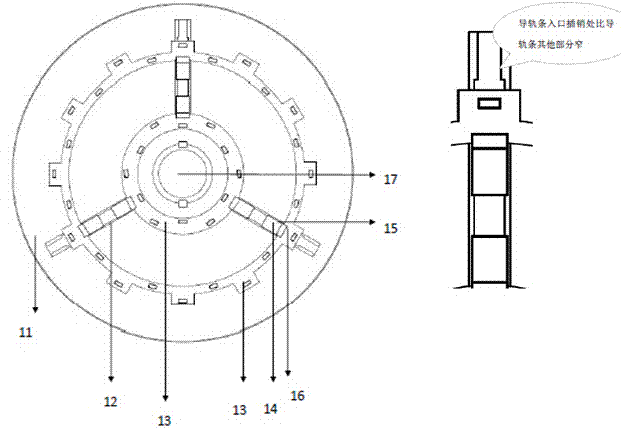

[0016] Implementation Mode 1: If figure 1 , a number of LED lamp bead rings with a circular chassis body structure

[0017] Step 1: Stamping out the guide rail (12) while forming the chassis (11) by mechanical stamping, According to the area of the circular chassis (11) with the center of the circle as the starting point, the guide rail strips (12) are evenly distributed in a diverging and radial manner, and the entrance end of the guide rail strips (12) (see figure 1 Partial enlarged view) is slightly narrower and the other parts keep the width matching the buckle (14). In general, three guide rail bars (12) are used, such as figure 1 As a benchmark, guide rail bars can be added according to the size of the circular chassis body (11) and the shape of the object to be fixed.

[0018] Step 2: Movable buckle (14) (short straight type) : The tongue (16) of the movable buckle (14) is facing outward to bite the fixed object, and the non-fixed end of the tongue (15) is stu...

Embodiment approach 2

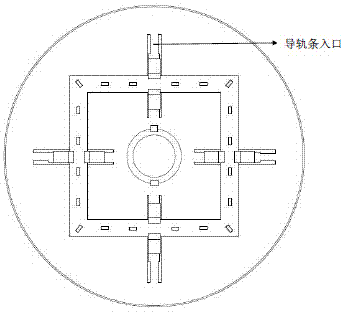

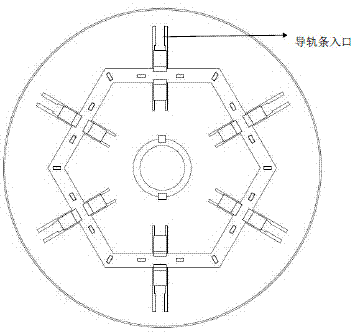

[0022] Implementation mode two: if Figure 6 The chassis body is square, and the driver is located between any two adjacent LED strips;

[0023] While mechanically punching and forming the square chassis body (62), according to Figure 6 As shown in the stamped guide rail (65), there are at least two guide rails (65) in the longitudinal direction of the guide rail (65), because there is only one up and one down two snap points In order to fix an LED lamp bead product (bar, ring, frame), there must be at least one guide rail (65) in the horizontal direction, and the length of the guide rail (65) is set according to the chassis area and the required mechanical strength. , the short guide rail (65) has higher mechanical strength than the long guide rail (65), and it can also be directly installed on the guide rail (65) by adding movable buckles (14) (61) (81) To increase the density of LED lamp bead products and improve the lighting effect;

[0024] The movable buckles (14)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com