Testing device for thickness of blank body in mechanical pressing

A technology of machine press forming and testing equipment, which is applied in the direction of measuring equipment, optical equipment, instruments, etc., can solve the problem that the size and thickness of the green body cannot be automatically controlled, and achieve the effect of improving production enthusiasm and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

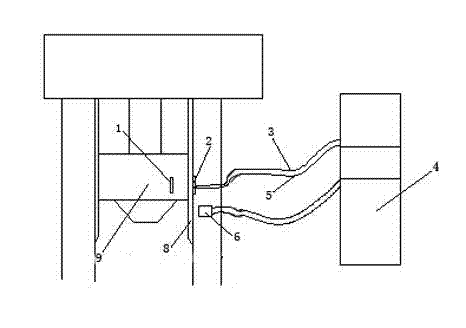

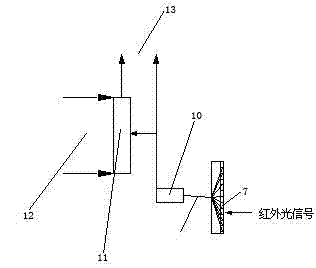

[0016] Such as figure 1 As shown, the present invention is a test device for the thickness of a green body during press forming. The overall structure is a control device 4 including a sensor device, which is preset with the optimal range of values for the required green body thickness and controls the operation of the press machine. The display device 6 for monitoring and suppressing the situation; the sensor device is composed of a sensing device one 1 and a sensing device two 2 installed oppositely; the sensing device one 1 is installed on the press slider 9, and the sensing device two 2 is installed on the press On the side wall 14 of the press next to the slideway; the first sensing device 1 and the second sensing device 2 are infrared sensors, which send and receive infrared signals to each other to sense the thickness of the green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com