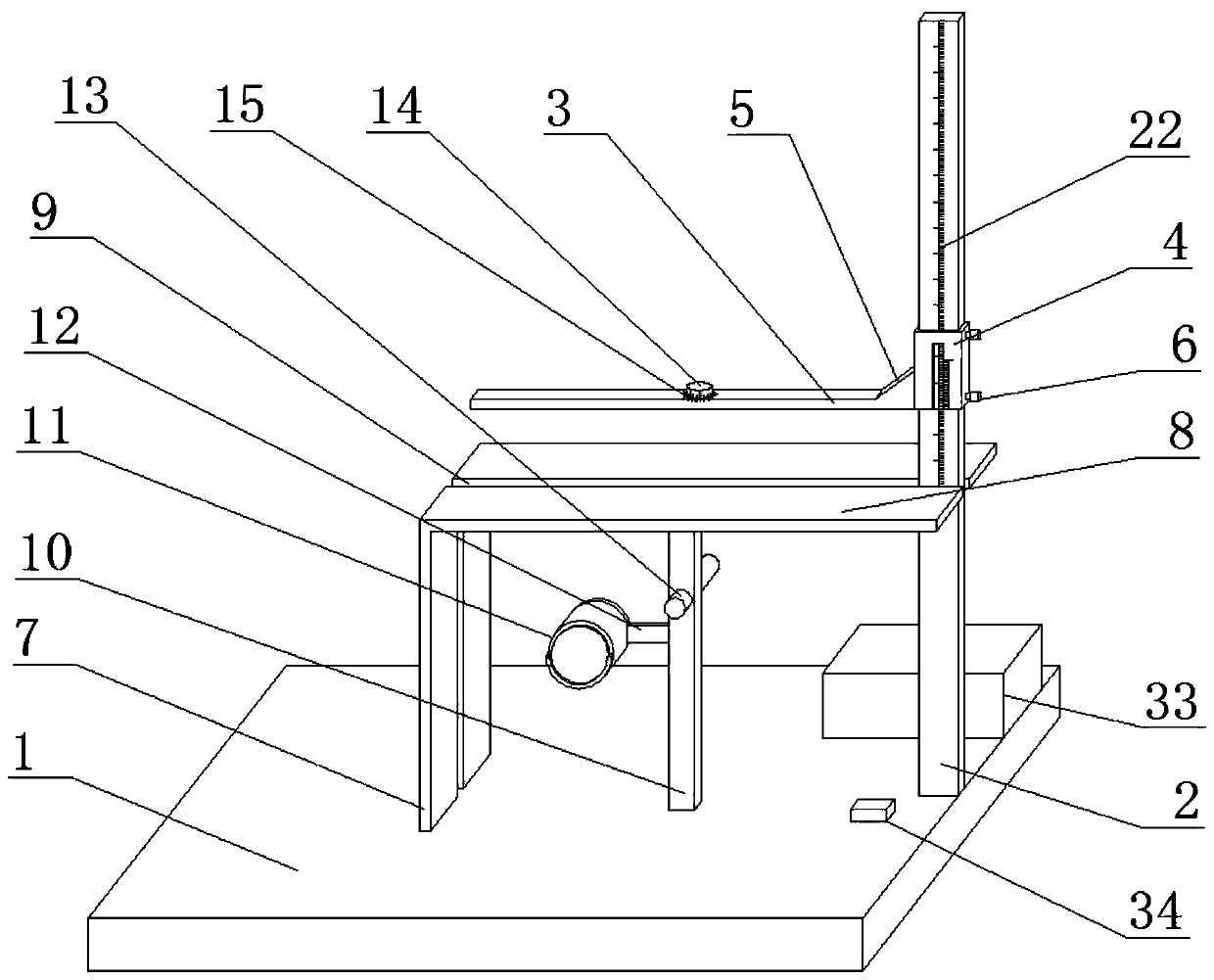

A device for detecting the thickness of a microcrystalline saw blade

A technology of thickness detection and microcrystalline stone, which is applied in the field of microcrystalline stone saw blade thickness detection devices, can solve the problem of inability to detect the roundness and flatness of microcrystalline stone saw blades, and the inconvenience of detecting the sawtooth thickness of microcrystalline stone saw blades. grain, can not guarantee the microcrystalline stone saw blade sawtooth thickness and frosted grain thickness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

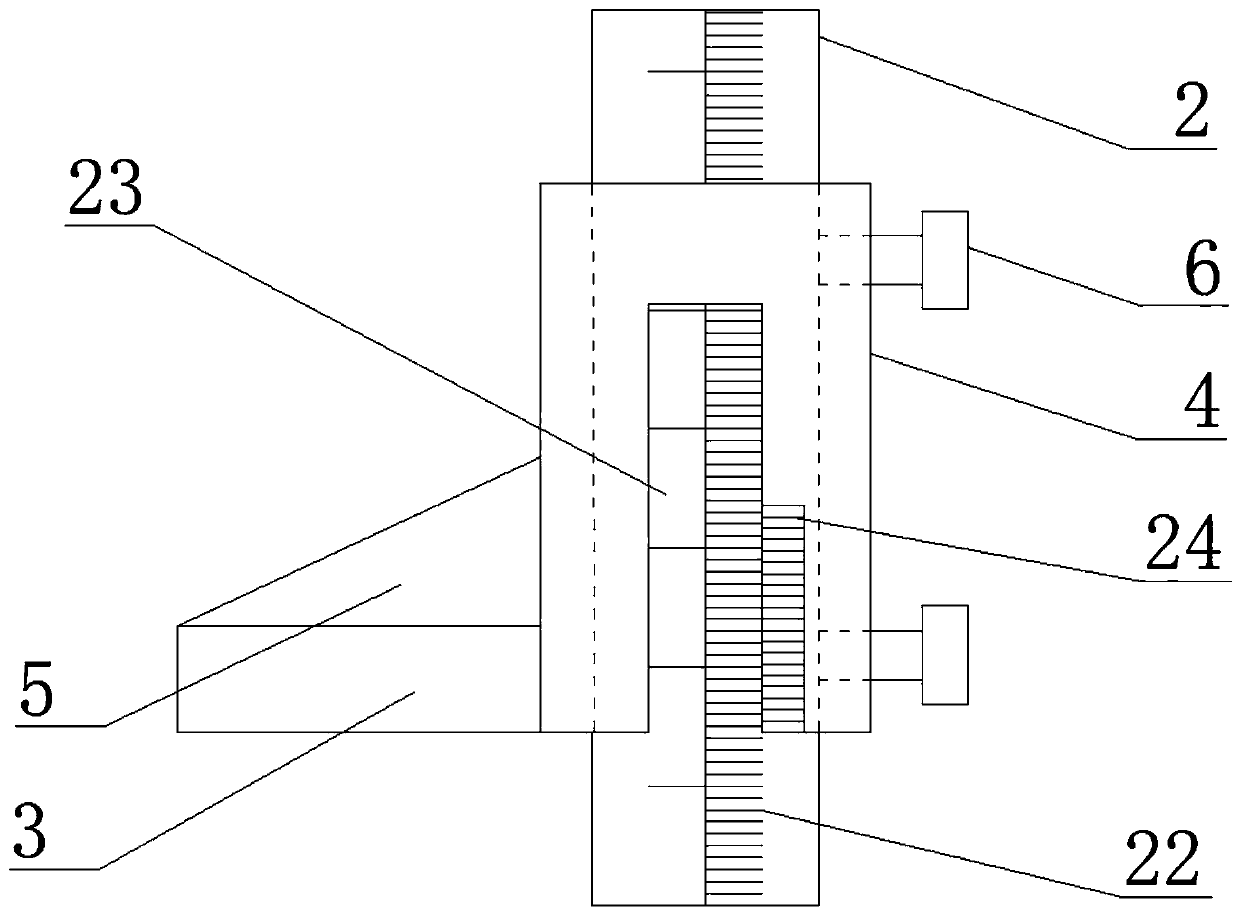

[0026] As a preferred embodiment of the present invention, the battery 33 is connected to the switch 34 through wires, and the switch 34 is connected to the lighting lamp 28 through wires.

[0027] As a preferred embodiment of the present invention, the bottom plate 30 is disposed on the bottom of the second magnifying glass 29 , and the ferrule 32 is sleeved on the outer side of the rotating shaft 31 .

[0028] As a preferred embodiment of the present invention, the number of the lighting lamps 28 is four, and the lighting lamps 28 are evenly distributed outside the magnifying glass one 27 .

[0029] As a preferred embodiment of the present invention, the switch 34 is arranged on one side of the pole one 2, the battery 33 is arranged on the other side of the pole one 2, and the other side of the flat plate 8 is welded on the pole one. Rod one 2 up.

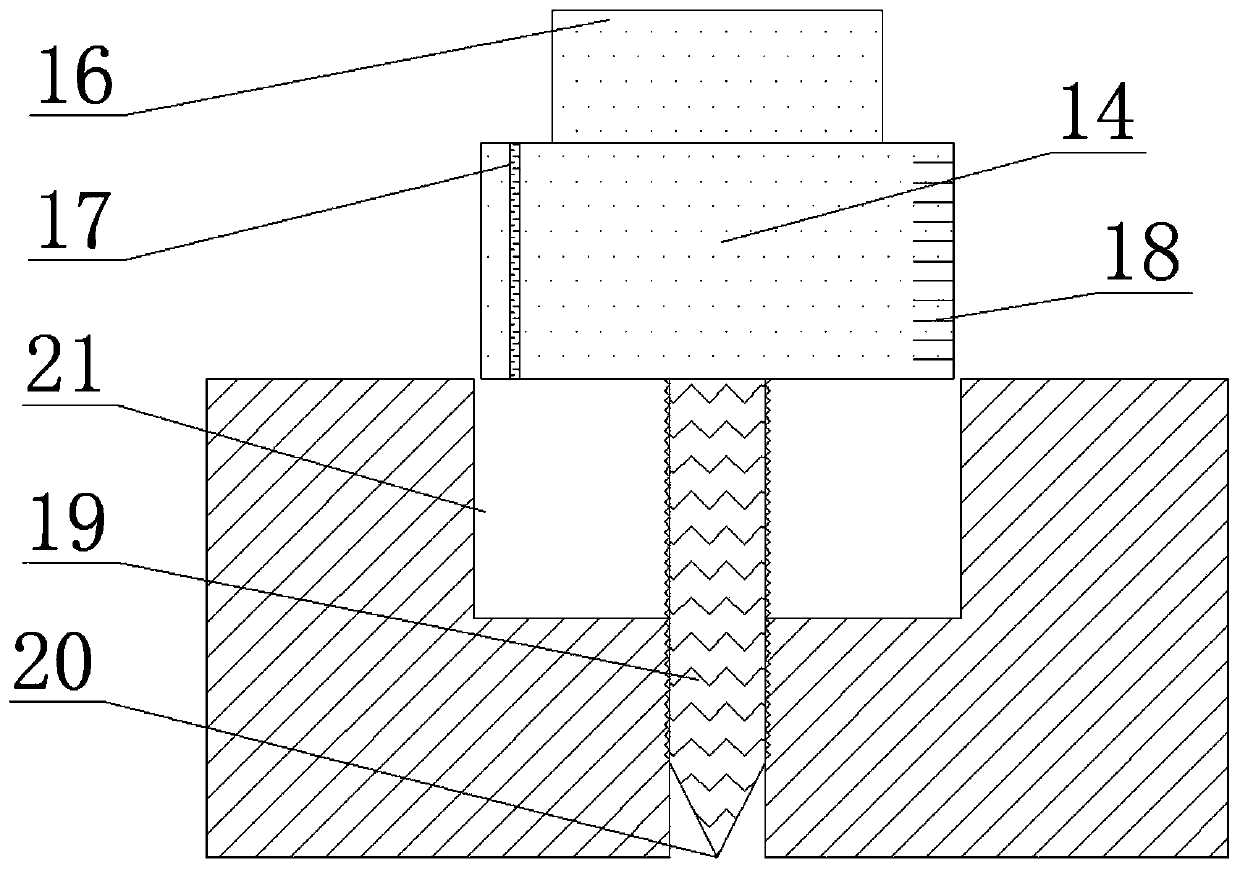

[0030] As a preferred embodiment of the present invention, the second pole 10 and the second magnet 26 are provided with a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com