Simulation and test device for complex working condition of wind turbine planet gear

A technology of planetary gears and wind turbines, which is applied in the field of simulation of complex working conditions of wind turbine planetary gears and the structural design of test devices, which can solve the problems that the vibration and noise of planetary gears have not been well resolved, and achieve variable shaft positions, The device is flexible and convenient, and the effect of optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, below in conjunction with accompanying drawing and embodiment the technical scheme of invention is further described as follows:

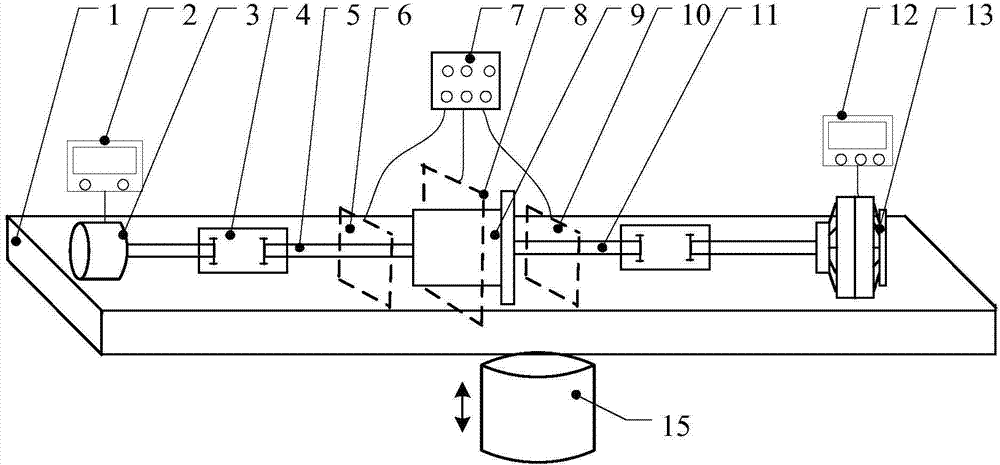

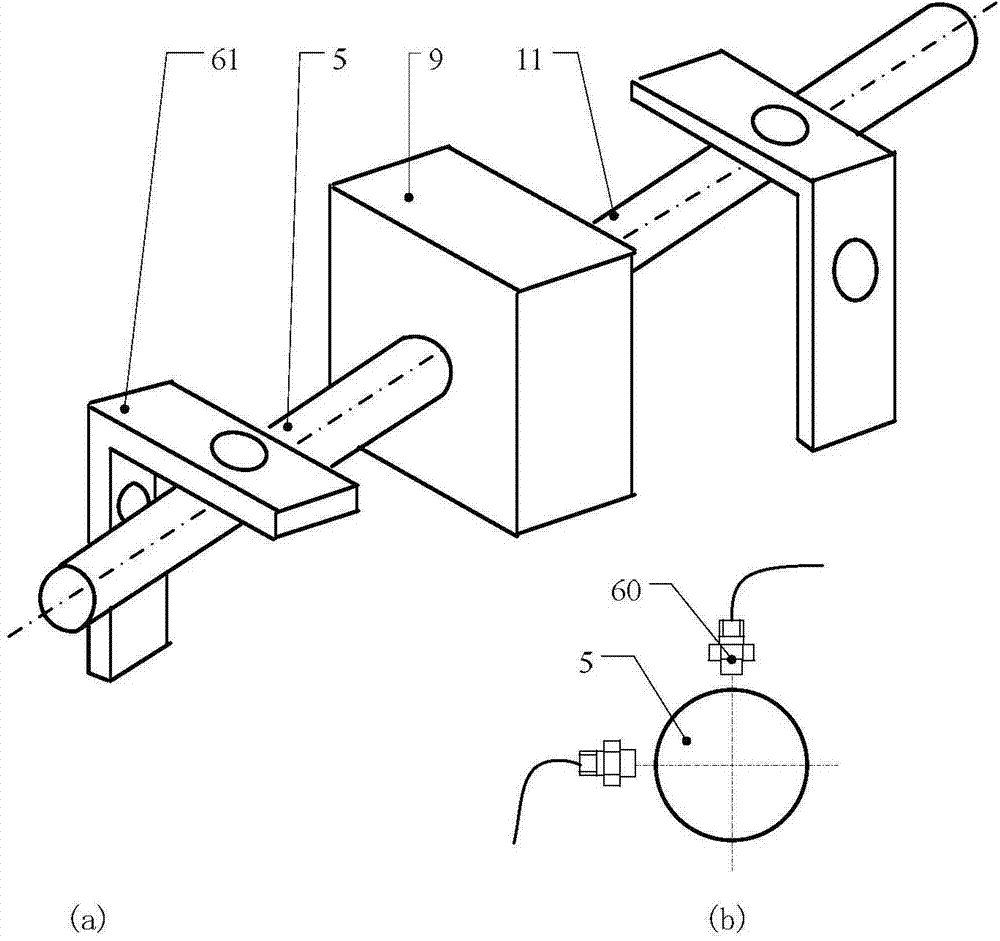

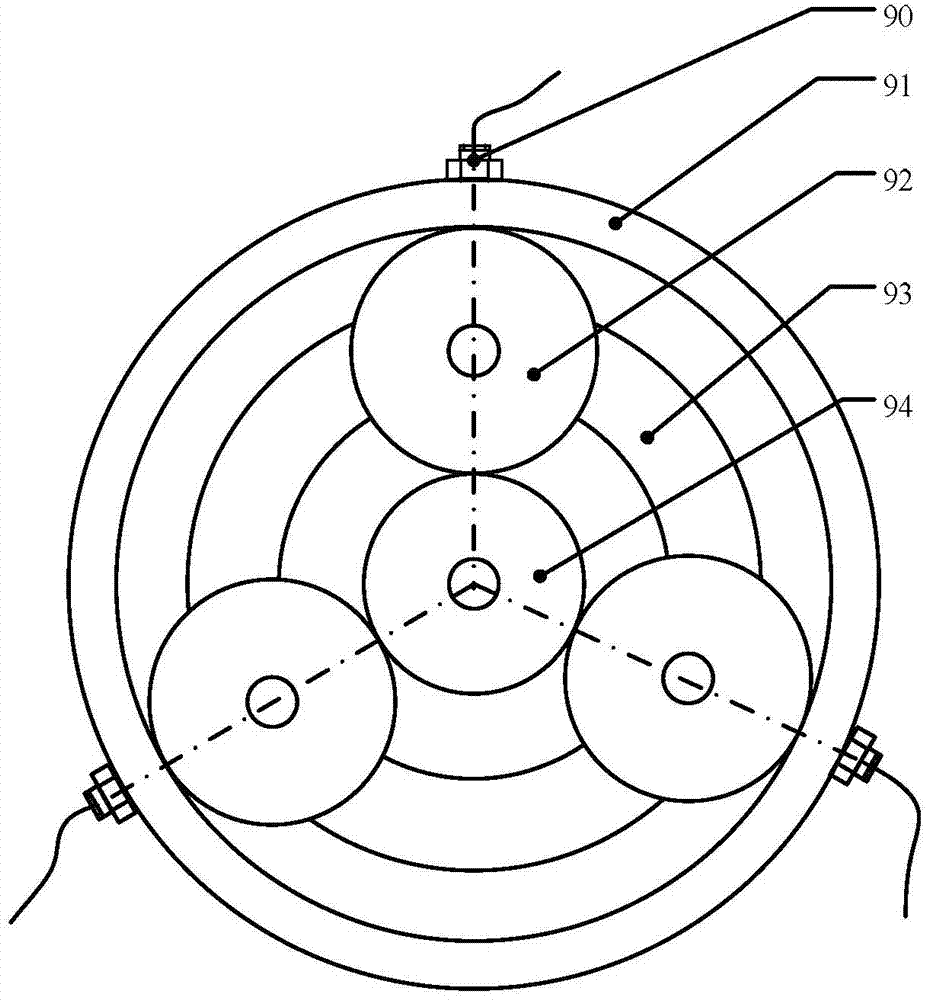

[0022] Embodiment 1 of the wind turbine planetary gear complex working condition simulation and testing device of the present invention has a composition structure as follows figure 1 As shown, the input shaft 5 of the wind turbine planetary gear, the planetary gear box 9 and the planetary gear output shaft 11 in the present embodiment are parts to be simulated and tested, and the simulation and test device includes a flat base 1, a motor controller 2, A servo motor 3, two diaphragm couplings 4, an eddy current sensor assembly, a signal collector 7, an acceleration sensor assembly, a magnetic powder brake controller 12, a magnetic powder brake 13, and a vibrating table 15; the components of the device The connection relationship is as follows: the servo motor 3 is connected to the motor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com