Water tank of concrete corrosion resistance tester

An anti-corrosion, testing machine technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as blocked pipelines, achieve low manufacturing and maintenance costs, good filtering effect, improve work efficiency and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

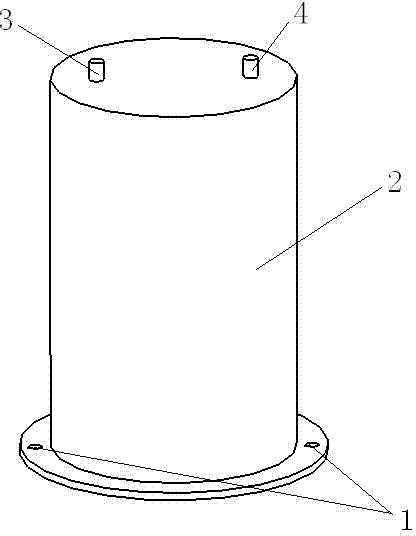

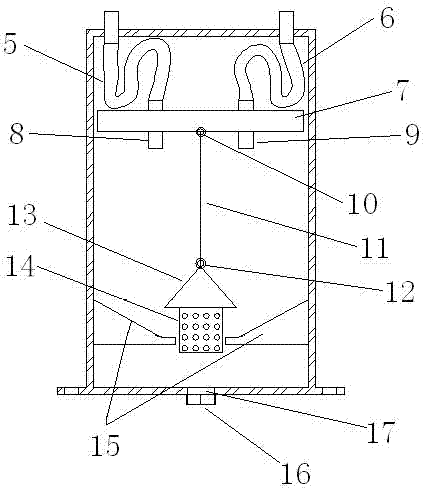

[0013] A concrete corrosion resistance testing machine water tank comprises a tank body 2, a circular floating plate 7, a nylon wire 11, a water inlet silicone steel wire hose 5, an outlet water silicone steel wire hose 6 and a waste shut-off valve 13.

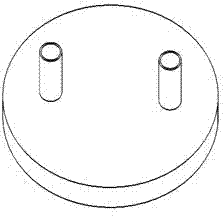

[0014] The box body 2 is a cylinder, the left side of the upper end surface of the box body 2 is the water inlet 3, the right side of the upper end surface of the box body 2 is the water outlet 4, and the middle position of the bottom surface of the box body 2 is the sewage outlet 17, and the sewage outlet is installed with a plug 16. The bottom surface of the body 2 is larger than the top surface of the box body 2, and the bottom surface of the box body 2 has two fixing holes 1, and the inside of the box body is provided with a circumferential slope 15.

[0015] Two PPR pipes are fixed on the circular floating plate 7, the left side is the water inlet PPR pipe 8, the right side is the water outlet PPR pipe 9, and the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com