Temperature and humidity control device for transformer substation

A temperature and humidity control, substation technology, applied in substation/switchgear cooling/ventilation, non-electric variable control, control/regulation system, etc., can solve problems such as reduced service life, high humidity, cabinet condensation, etc. Guaranteed service life, reasonable structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

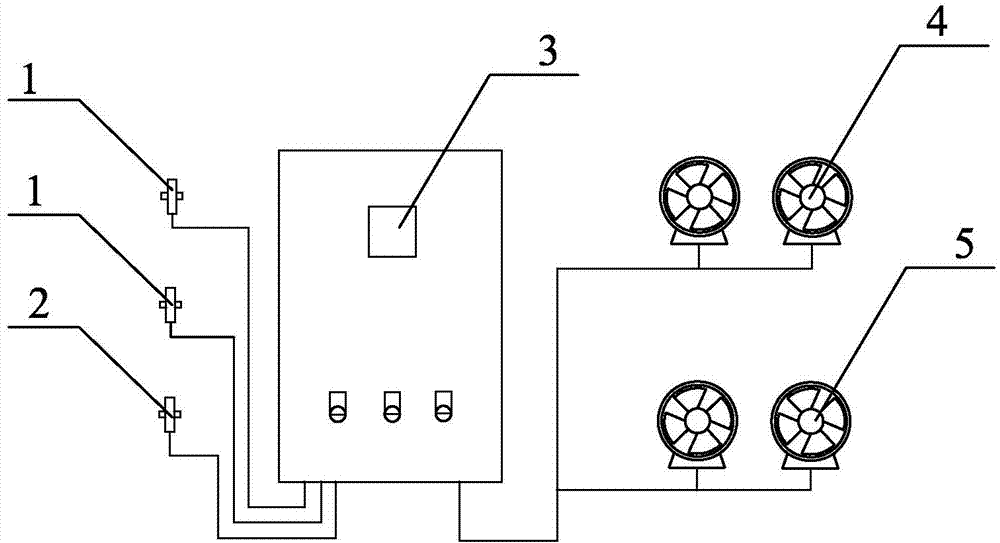

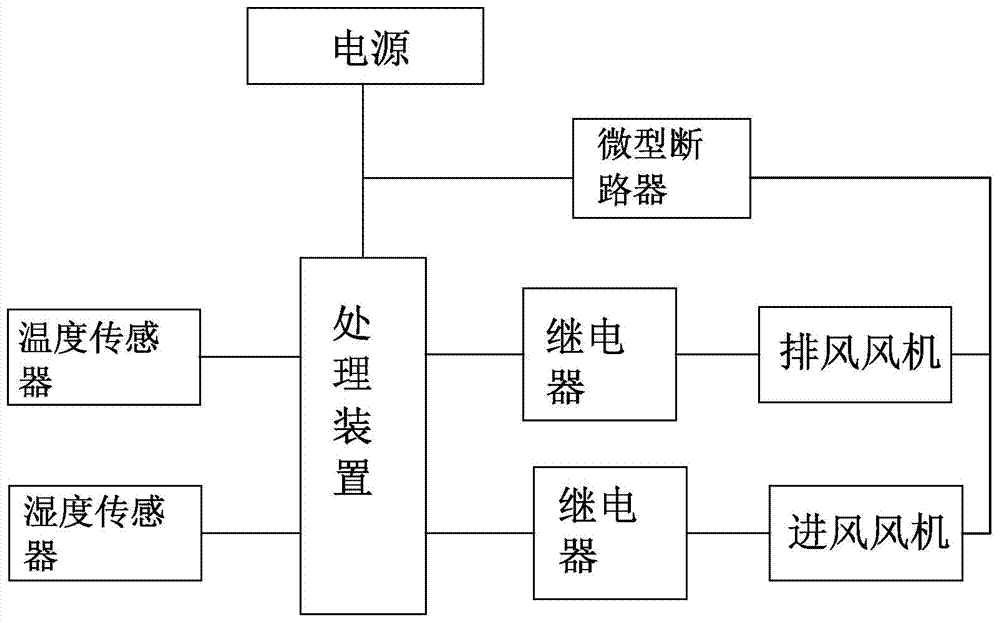

[0016] Such as figure 1 The shown substation temperature and humidity control device includes a temperature sensor 2, a humidity sensor 1, an exhaust fan 4, an air intake fan 5, and a control box 3. The control box 3 is installed in the substation, and the temperature sensor 2 and the humidity sensor 1 are connected by a data line. The control box 3, the exhaust fan 4 and the air intake fan 5 are controlled by the control box 3; there is a processing device in the control box 3, the processing device is connected to the temperature sensor and the humidity sensor, and the processing device is connected to the air intake fan and the exhaust fan through a relay. wind blower.

[0017] Two humidity sensors and one temperature sensor are connected to the processing device through a 20-meter-long data cable, which can be freely placed in every corner of the substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com