Flexible heating sheet and manufacturing method thereof

A heating element, flexible technology, applied in the field of flexible heating element and its preparation, can solve the problem of heating parts that cannot have a curved surface, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the above-mentioned flexible heating sheet, including:

[0038] S1. Set the positive electrode pattern and the negative electrode pattern on the insulating insulation layer;

[0039] S2. Fill the electrothermal ink between the positive electrode pattern and the negative electrode pattern on the insulation layer, so that the electrothermal ink is in electrical contact with the positive electrode pattern and the negative electrode pattern at the same time, forming a heating function layer;

[0040] S3. An insulating heat radiation layer is provided on the heat generating functional layer.

[0041] In the above step S1, as mentioned above, the positive electrode pattern and the negative electrode pattern can be independently selected from one of aluminum, copper, and silver. The above-mentioned positive electrode pattern and negative electrode pattern can be prepared by various conventional methods, such as punchi...

Embodiment 1

[0050] This embodiment is used to illustrate the flexible heat sink disclosed in the present invention and its preparation method.

[0051] Take 0.1mm thick PET film as insulation layer.

[0052] A metal aluminum layer with a thickness of 0.007mm is pasted on the upper surface of the insulation layer as the positive electrode pattern and the negative electrode pattern. Then, electrothermal ink with a thickness of 0.02 mm is printed between the positive electrode pattern and the negative electrode pattern, so that the electrothermal ink fills the gap between the positive electrode pattern and the negative electrode pattern, and is electrically connected to the positive electrode pattern and the negative electrode pattern at the same time. A heat generating functional layer is formed.

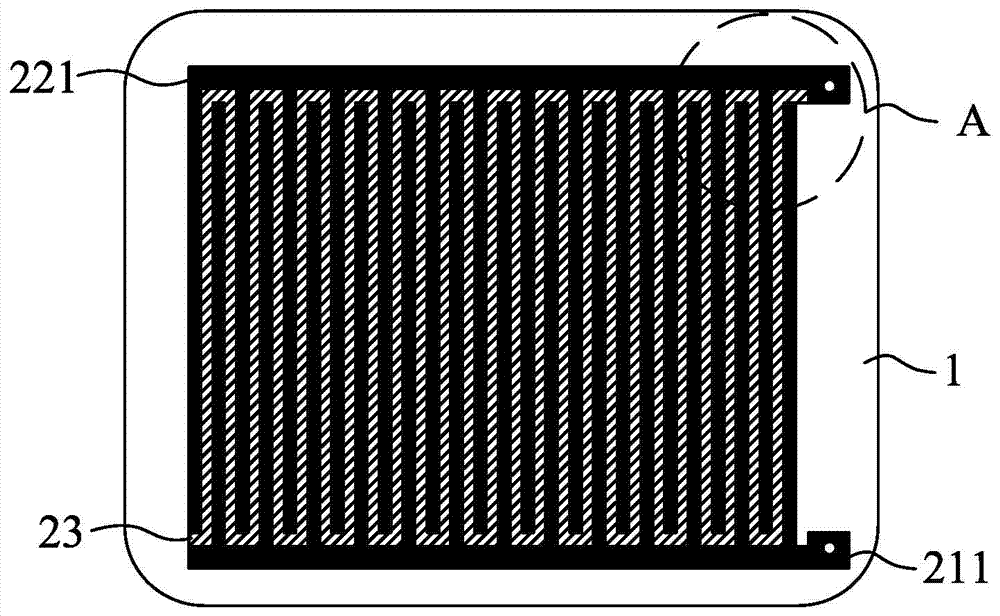

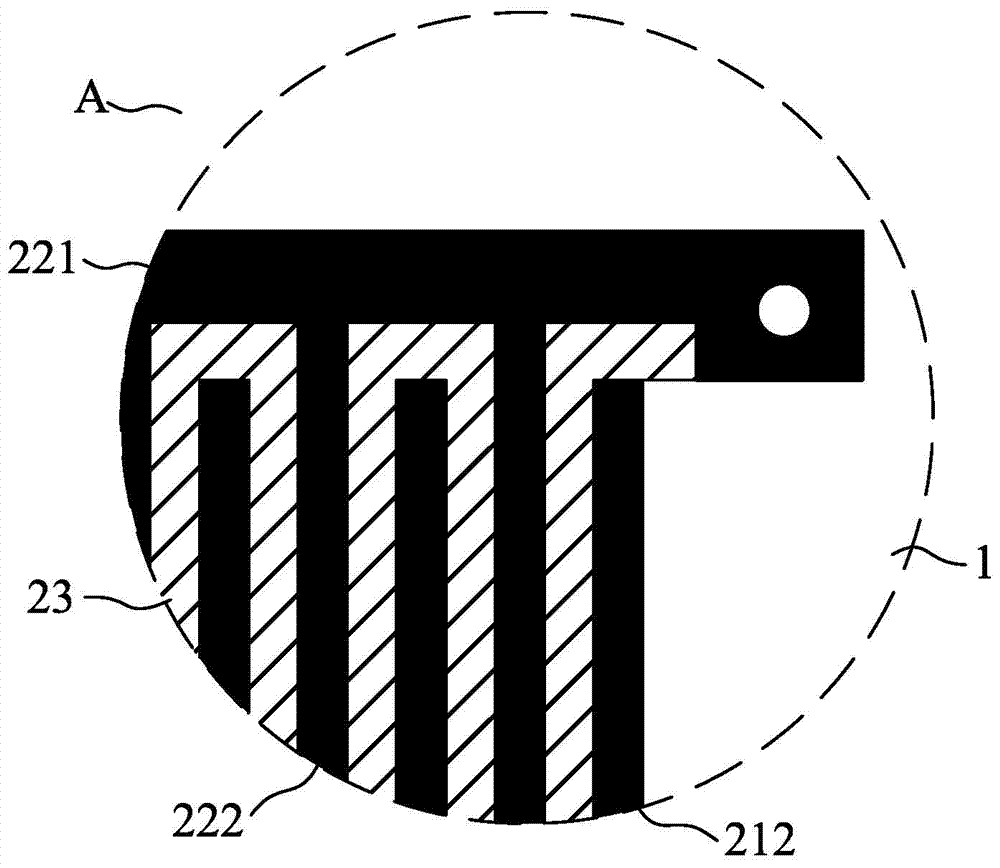

[0053] The structure of the heating function layer on the surface of the insulation layer is as follows: figure 1 and figure 2 shown. Wherein, the positive electrode pattern, the negative el...

Embodiment 2

[0063] This embodiment is used to illustrate the flexible heat sink disclosed in the present invention and its preparation method.

[0064] Take 0.05mm thick PET film as insulation layer.

[0065] A metal silver layer with a thickness of 0.1 mm is pasted on the upper surface of the insulation layer as the positive electrode pattern and the negative electrode pattern. Then, electrothermal ink with a thickness of 0.05mm is printed between the positive electrode pattern and the negative electrode pattern, so that the electrothermal ink fills the gap between the positive electrode pattern and the negative electrode pattern, and is electrically connected to the positive electrode pattern and the negative electrode pattern at the same time. A heat generating functional layer is formed. The structure of the heat generating functional layer is the same as in Example 1.

[0066] The width of the above-mentioned sub-positive electrode strips is 8mm, the width of the sub-negative elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com