A biomass carbonization raw material forming unit

A molding unit and biochar technology, applied in the direction of material molding presses, mixers, presses, etc., can solve the problems of waste of resources, difficult crushing, wet materials, etc., and achieve the effect of convenient movement and reduced belt connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

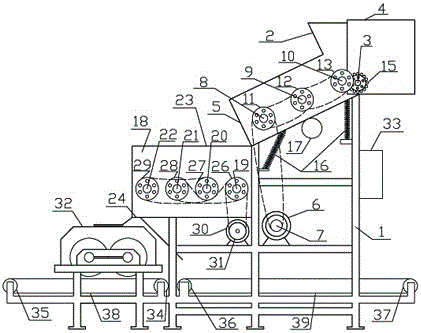

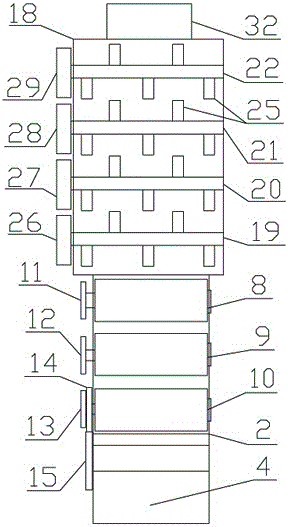

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] The direction of the vertical drawing surface is specified as the left and right directions.

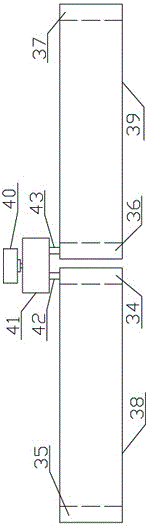

[0023] A biomass carbonization raw material molding unit, including a mill, a mixer, a molding machine 32 and a support 1, the mill, the mixer, and the molding machine 32 are all fixed on the bracket 1, and the mill includes Cabinet 2, feed roller 3 and three grinding rollers, the upper end of the cabinet 2 is provided with a first feed port 4, and the bottom is provided with a first discharge port 5, and the feed roller 3 is installed in the cabinet On the left and right walls of 2, the left and right walls of the cabinet 2 are provided with bearing assembly holes respectively, and the bearings are installed on the cabinet 2 through the bearing assembly holes, and the three grinding rollers are assembled on the cabinet 2 through the bearings on the left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com