Roller type water-removed leaf air separator

A drum-type, wind-separator technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of inability to meet the requirements of high-quality green tea greening process, inconsistent fresh leaf picking standards, and adverse effects. High-quality green tea quality and other issues, to achieve the effect of ingenious design, reduced volume and weight, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

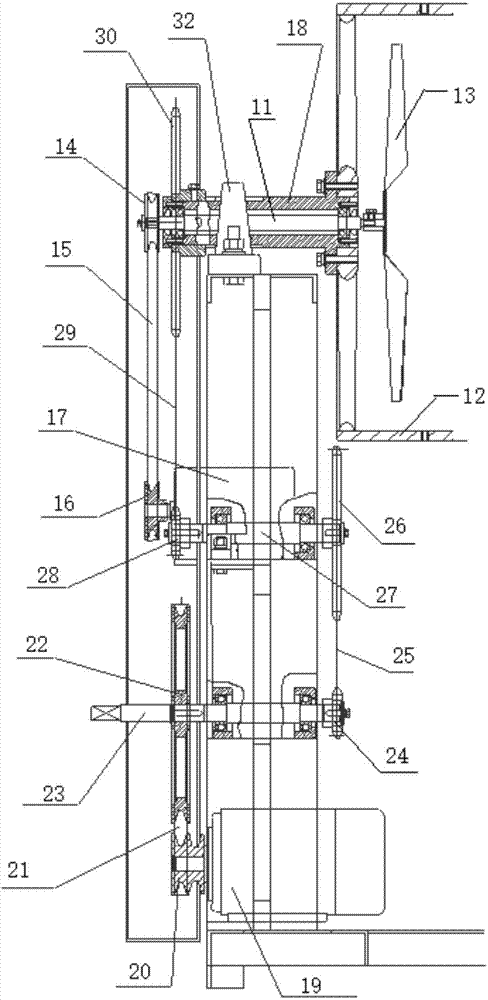

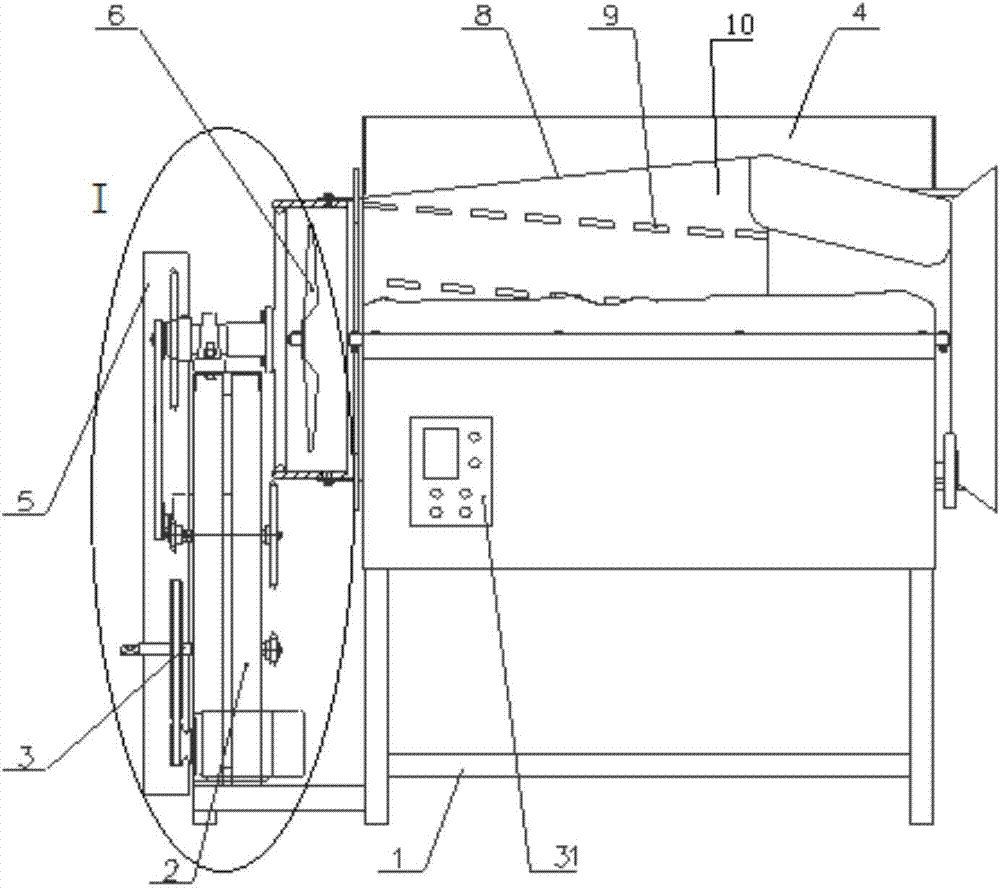

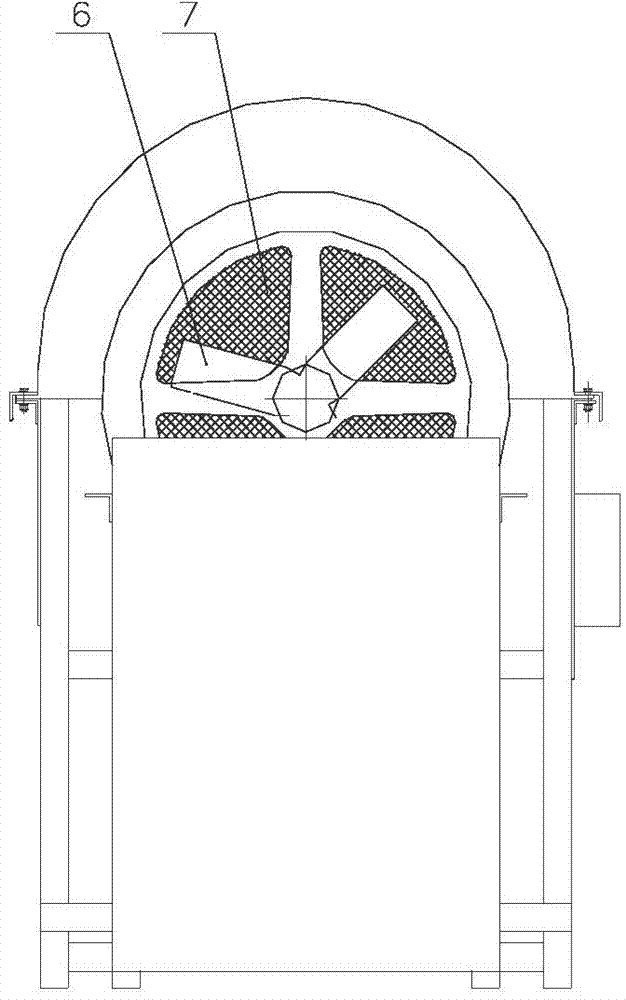

[0024] The structure of a kind of drum type finishing leaves air separator provided by the invention is as follows: figure 1 and figure 2 As shown, it at least includes a drum, a casing 4, a drum bracket 1, a fan mechanism 6, a transmission mechanism 3, a transmission bracket 2 and a frequency conversion control box 31. The transmission support 2 is fixed on the drum support 1. The drum is composed of a cylinder body 8 and an isolation screen 7 . The cylinder body 8 is composed of two conical half cylinders, the whole is in the shape of a waist drum, the cylinder body is fixed on the shell, and the shell 4 is fixed on the roller support. The isolation net plate 7 is encapsulated in one port of the cylinder body, and the other port of the cylinder body is the tea inlet and outlet.

[0025] Fan mechanism 6 comprises fan shaft 11, fan casing 12, fan blade 13, fan p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com