Screw fastener assembling device

A technology for assembling devices and fasteners, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, long working time, high labor intensity, etc., to reduce labor intensity and meet the needs of enterprises , The effect of simple assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

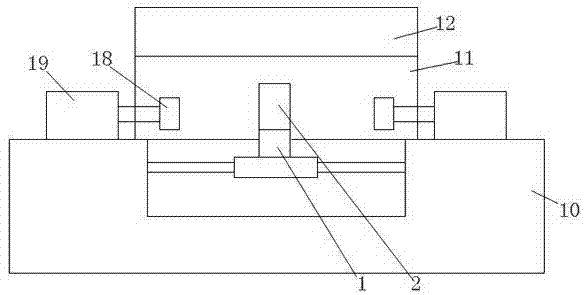

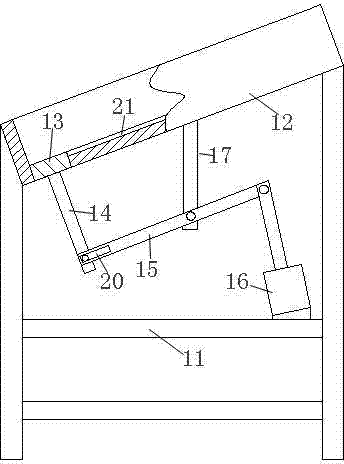

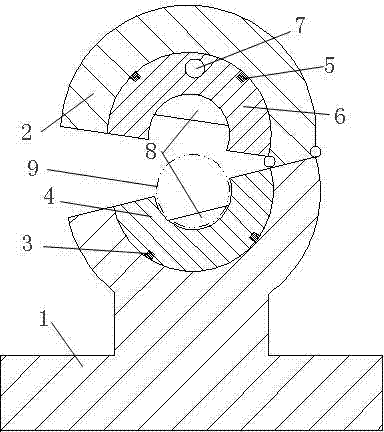

[0018] refer to Figure 1 to Figure 3 , the present invention relates to a screw fastener assembly device, comprising a machine base 10 and a frame 11 for conveying the screw, the base is connected with a base 1 for assembling the screw through a screw pair, the said The base is hinged with a loam cake 2 that realizes screw rod 9 hooping, and the top of the frame is fixedly provided with a trough-shaped platform 12 for conveying the screw rod. The inner wall is provided with a lower positioning column 3, and the base is positioned and connected with a lower semi-annular sleeve block 4 through the lower positioning column. The inner wall of the upper positioning column is provided with an upper positioning column 5, and the upper positioning column is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com