Movable-type grinding wheel polisher dust hood, dust collecting device and dust control method

A technology of dust collecting device and dust collecting hood, which is applied in the fields of dust collecting hood, dust collecting device and dust removal and dust collection, can solve the problems such as affecting the operation of workers, cannot be used normally, complicated structure, etc., and achieves good sealing effect and stable work. , The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

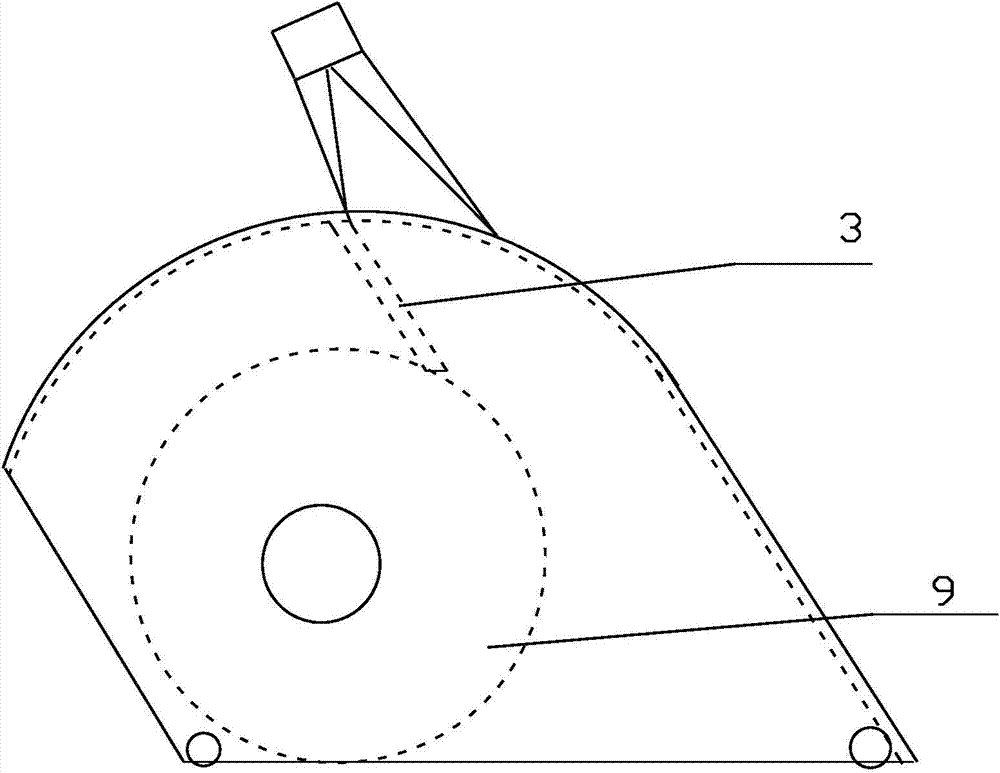

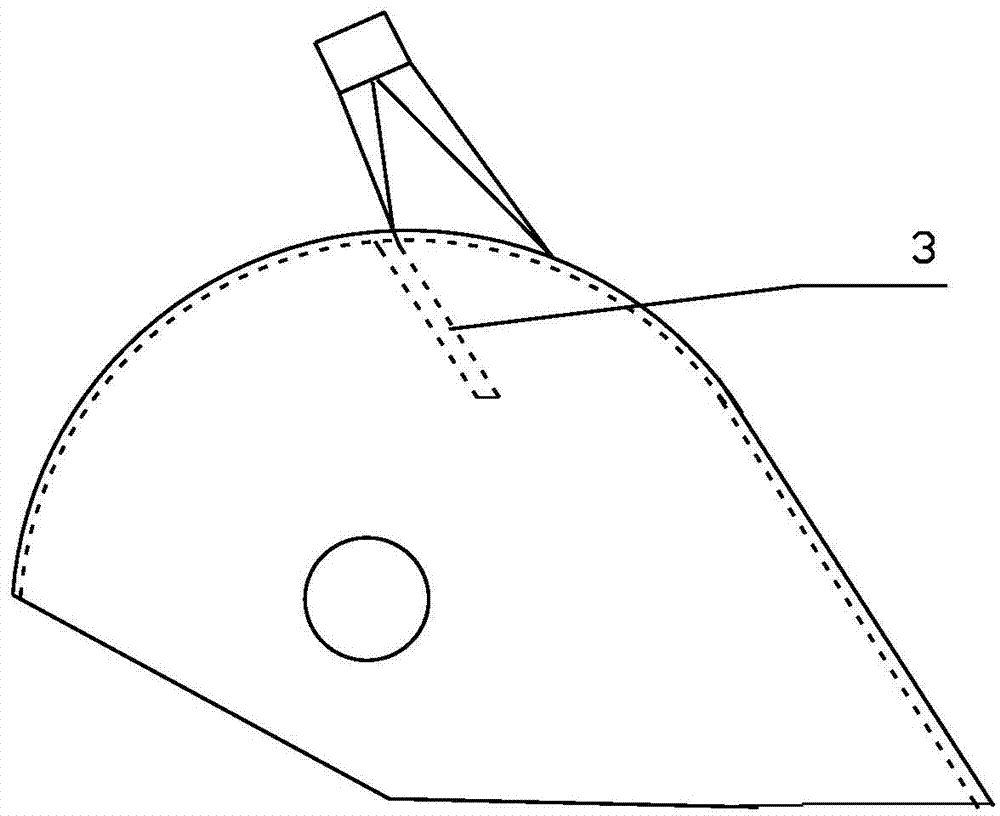

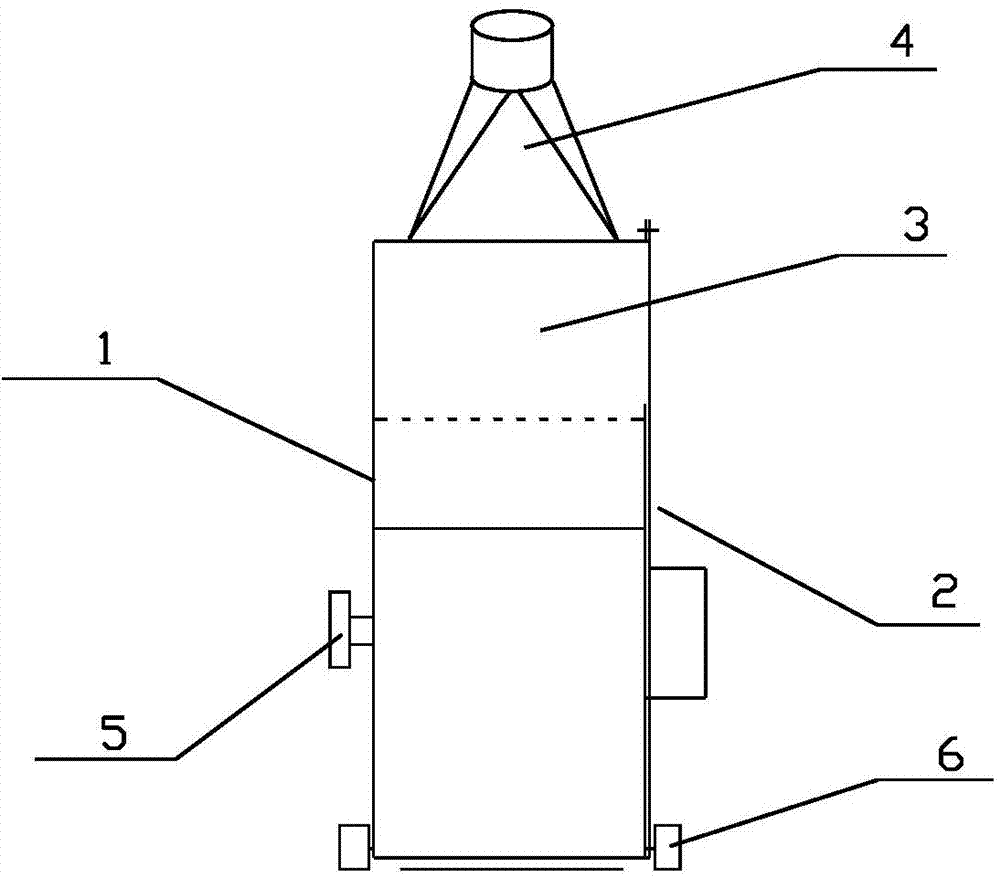

[0027] Such as Figure 1-4 As shown, a dust collection device for a mobile grinding wheel grinder includes a dust collection cover 1, a cover plate 2, a deflector plate 3 and an air collecting pipe 4. The dust collection cover 1 is a semi-closed grinding wheel dust collection cover. The dust collection cover 1 is fixed on the frame of the grinding wheel grinder and covered on the grinding wheel 9 of the grinding wheel grinder. The outer contour curve of the dust collection cover 1 is an involute or an eccentric circle. , to facilitate airflow collection and reduce resistance loss. The front part adopts a straight line section tangent to the curve to increase the volume of the air collection chamber, so as to diffuse and decelerate the dust, which is convenient for the air collection airflow to collect dust. The dust collection cover 1 can be processed by sheet metal, or can be molded from non-metallic materials such as plastics.

[0028] The cover plate 2 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com