Stratospheric aerostat skin and preparation method thereof

An aerostat and stratospheric technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of bursting, poor thermal conductivity, etc., to improve stability, improve thermal conductivity, and improve overall mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

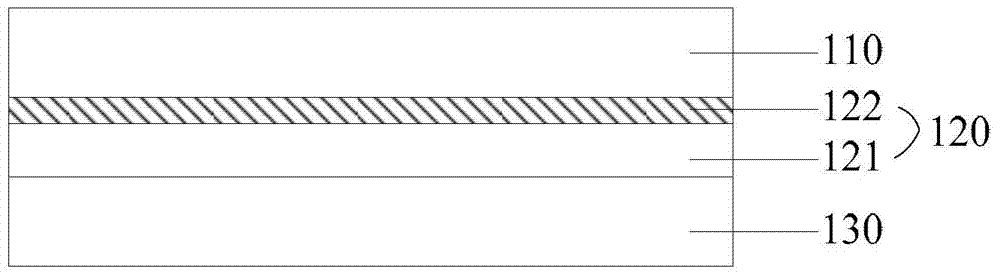

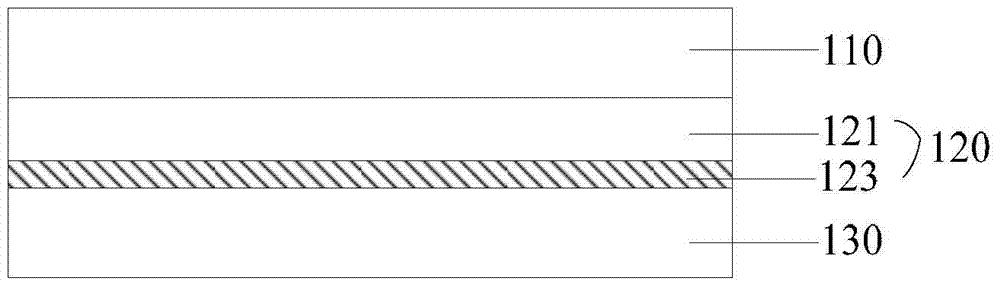

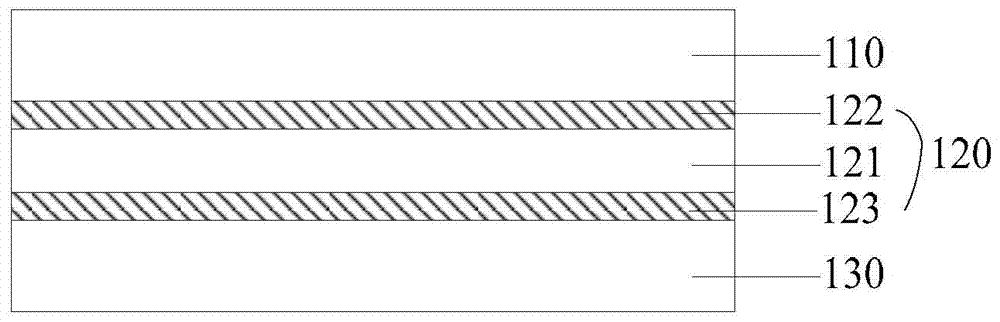

[0034] In addition, according to another aspect of the present invention, there is also provided a method for preparing the skin of a stratospheric aerostat, which includes the following steps: forming a first graphene-resin layer on the first surface of the aluminized PET layer 121 122, and / or form a second graphene-resin layer 123 on the second surface of the aluminized PET layer 121, thereby forming the first gas barrier layer 120; and the weather-resistant layer 110, the first gas barrier layer 120 and the bearing The layers 130 are stacked one after the other, and then heat-pressed to form the skin of the stratospheric aerostat.

[0035] In the above preparation method provided by the present invention, a graphene-resin layer is added on the first surface and / or the lower surface of the aluminum-coated PET layer 121 of the skin of the stratospheric aerostat. This can significantly improve the overall thermal conductivity of the stratospheric aerostat skin. In practical a...

Embodiment 1

[0045] On the first surface of the aluminized PET layer, the graphene-acrylic polyurethane photosensitive resin mixed glue is coated, and cured under ultraviolet light irradiation to form an aluminized PET layer with a graphene-photosensitive resin glue layer on the first surface, as the second A gas barrier layer is standby; wherein, the content of graphene in the graphene-photosensitive resin adhesive layer is 10wt%;

[0046] One side surface of the PBO fabric layer is coated with graphene-thermoplastic polyurethane hybrid glue, and after curing, a load-bearing layer with a second gas barrier layer is formed on the side surface for subsequent use; wherein, the graphene in the graphene-thermoplastic polyurethane glue layer The content is 20wt%; the ETFE layer, the first thermoplastic polyurethane film, the first gas barrier layer, the second thermoplastic polyurethane film, and the load-bearing layer with the second gas barrier layer on one surface are laid up from bottom to t...

Embodiment 2

[0050] On the first surface and the second surface of the aluminized PET layer, the graphene-acrylic polyurethane photosensitive resin mixed glue is coated respectively, and cured under ultraviolet light irradiation to form the graphene-photosensitive resin glue on the first surface and the second surface The aluminum-coated PET layer of the first layer is used as the first gas barrier layer; wherein, the content of graphene in the graphene-photosensitive resin adhesive layer is 10wt%;

[0051] One side surface of the PBO fabric layer is coated with graphene-thermoplastic polyurethane hybrid glue, and after curing, a load-bearing layer with a second gas barrier layer is formed on the side surface for subsequent use; wherein, the graphene in the graphene-thermoplastic polyurethane glue layer The content is 20wt%; the ETFE layer, the first thermoplastic polyurethane film, the first gas barrier layer, the second thermoplastic polyurethane film, and the load-bearing layer with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com