Longitudinal moving windscreen wiper

A technology of longitudinal movement and wiper, which is applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problem of incomplete drainage of rainwater and achieve the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Examples: The following specific examples illustrate the implementation of the invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

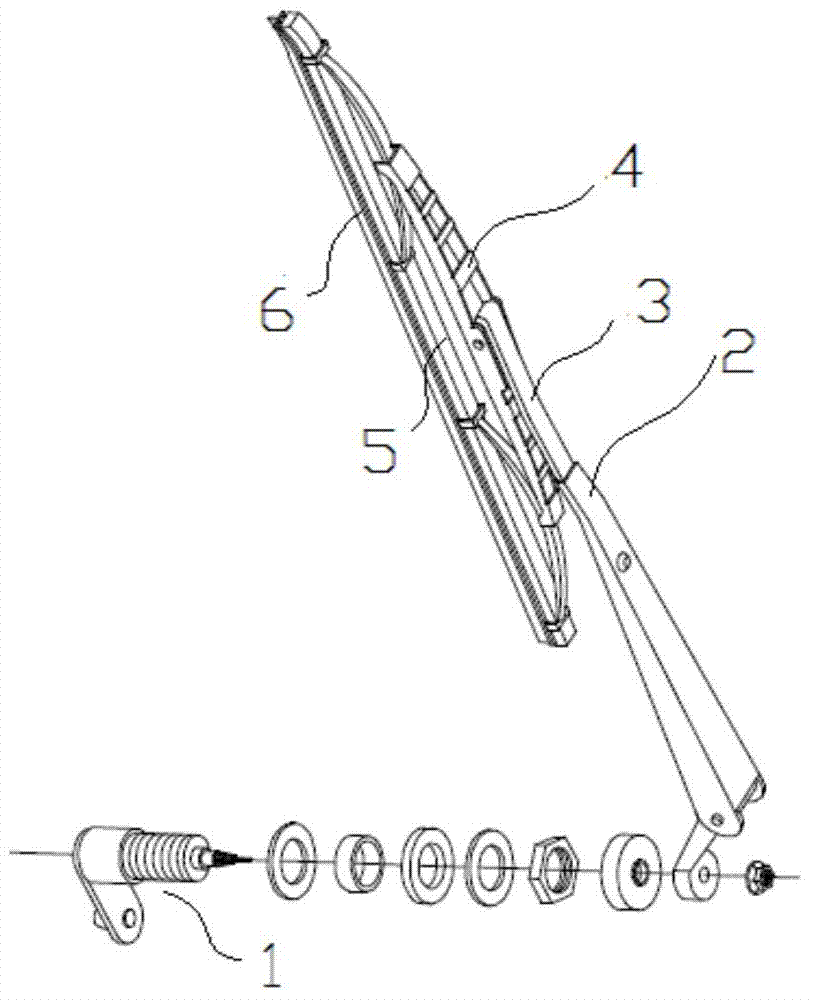

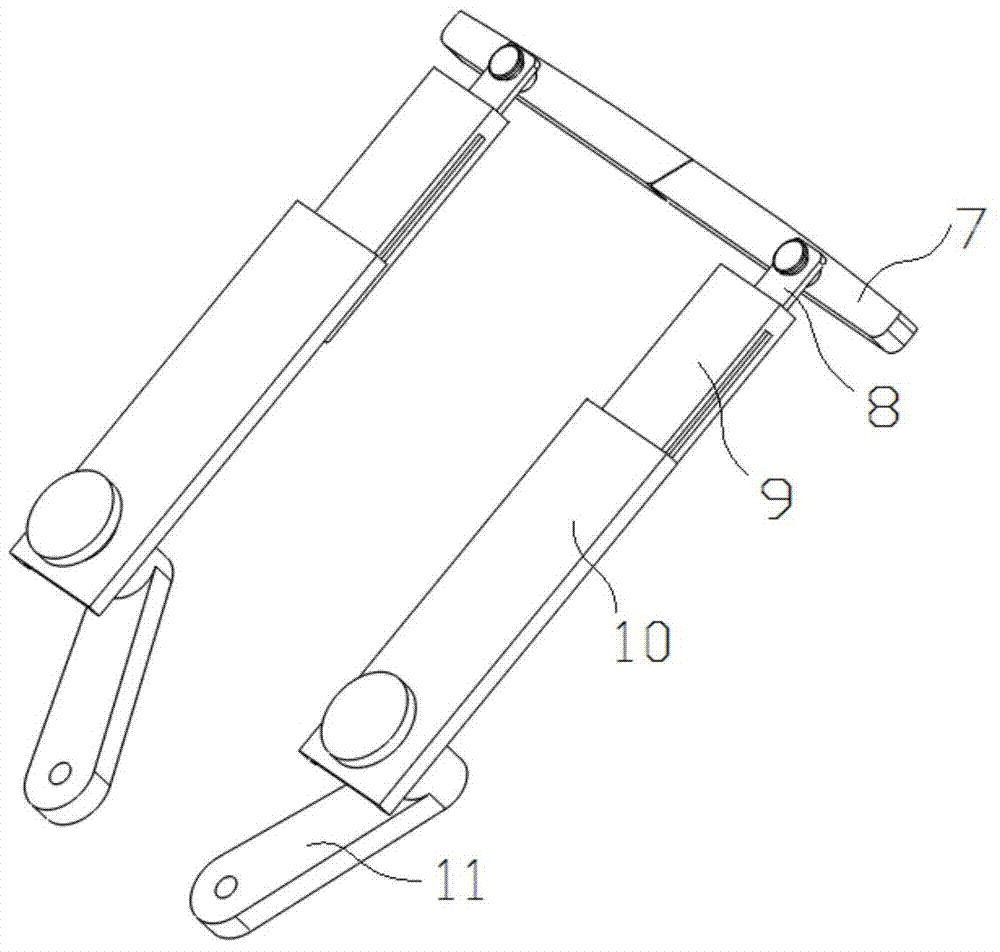

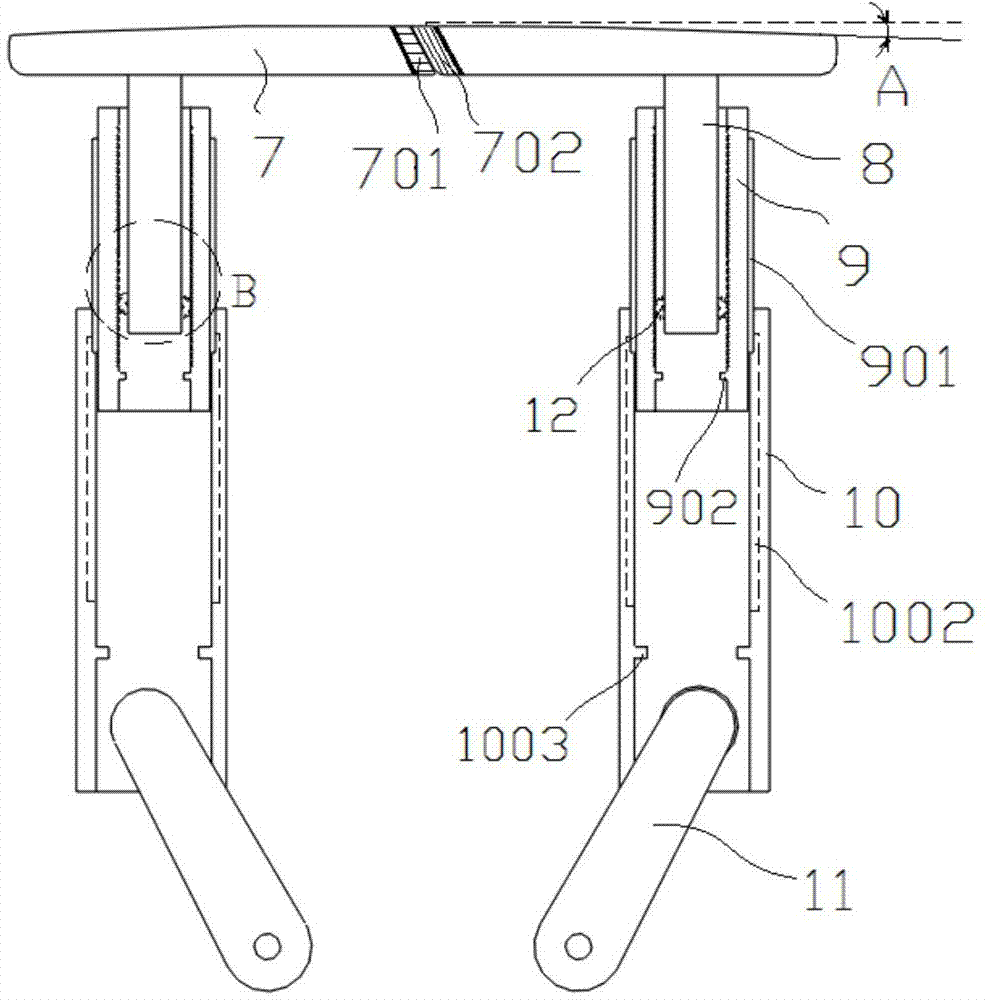

[0020] Such as figure 2 , image 3 and Figure 4 As shown, the longitudinally movable wiper includes a wiper blade 7 , a wiper gear arm 8 , a wiper rack arm 9 , a wiper arm 10 , a wiper arm spindle 11 and a gear 12 . The wiper blade of the longitudinally moving wiper adopts an integrated structure of two wiper blades. The two wiper blades 7 are respectively wrapped with a magnet at the respective connection ends 701 and 702. The magnet at the end 701 is the N pole, and the magnet at the end 702 is the S pole. When the wiper is working, the two originally separated wiper blades are combined into an integral wiper blade due to the mutual attraction of the opposite magnetic poles. The wiper blade 7 is hingedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com