Chemical material anti-corrosion agent storage tank

A technology for anti-corrosion and storage tanks, which is applied in the field of anti-corrosion agent storage tanks for chemical materials. It can solve the problems of continuous storage of agents that affect the service life of the inner wall of the tank, reduce the effect of scraping, corrosion of anti-corrosion coatings, etc., and achieve improved scraping liquid. Efficiency, increase efficiency, reduce corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

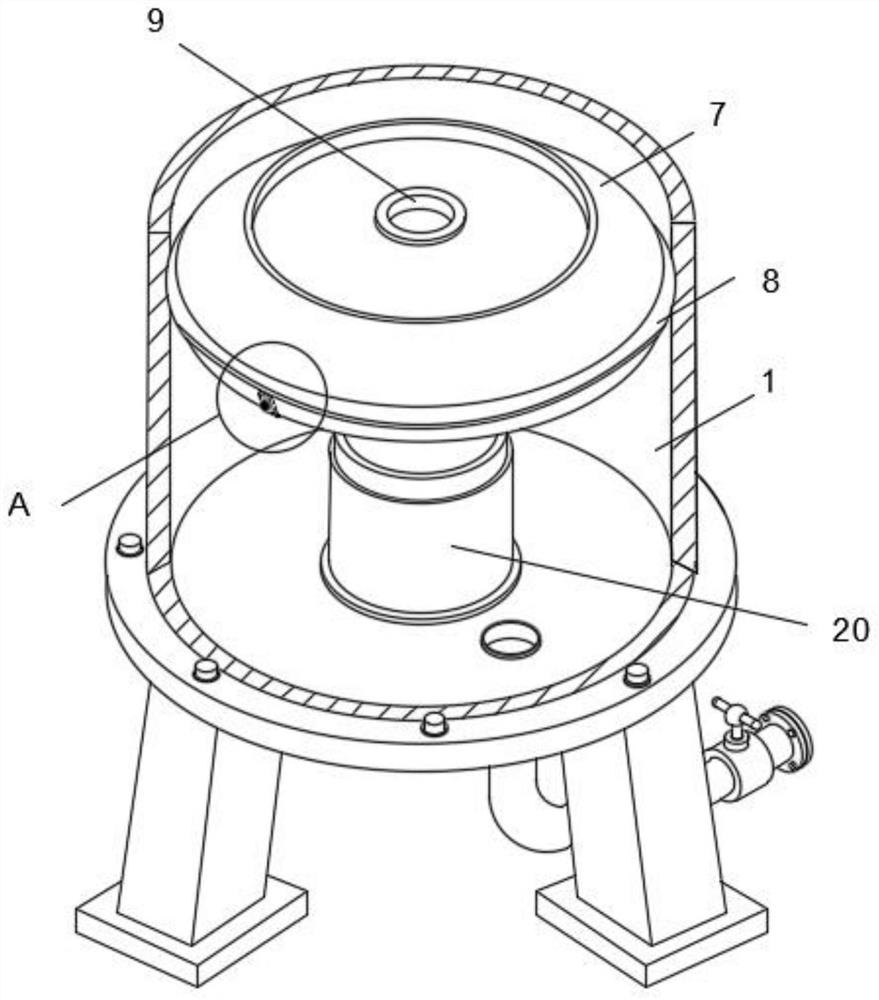

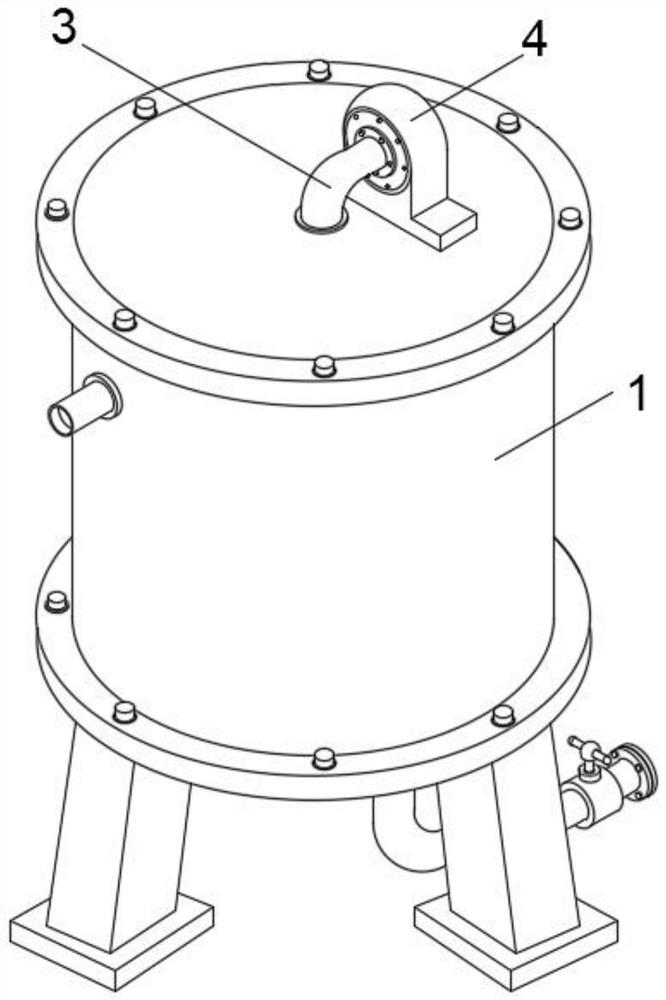

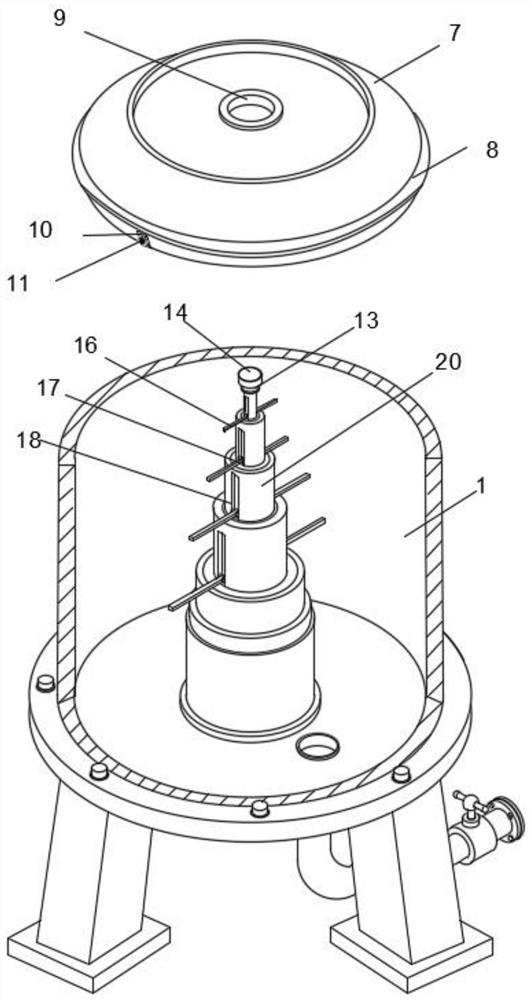

[0042] see Figure 2-8 , a chemical material anti-corrosion agent storage tank includes a tank body 1, the inner end of the tank body 1 is provided with a circular scraper 7, and the outer end of the circular scraper 7 is fixedly connected with clear liquid that abuts against the inner wall of the tank body 1 The silicone ring 8 and the circular scraper 7 are fixedly connected with a support frame 12 inside, and the outer end of the support frame 12 is fixedly connected with a plurality of booster protrusions 15 extending to the inside of the clear liquid silicone ring 8, and the upper end of the circular scraper 7 An air collecting hole 9 is opened, and the clear liquid silicone ring 8 is filled with a plurality of inflatable air bags 6 connected to the air collecting hole 9, and the inflatable air bags 6 and the pressurizing protrusions 15 are arranged at intervals.

[0043] see Figure 5 , Figure 6 , the lower end of the circular scraper 7 is provided with an inwardly re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com