Floating installation method for upper assembling block of tension leg platform

A technology of tension leg platform and block, which is applied to ship parts, transportation and packaging, ships, etc., can solve the problems of high capacity requirements of ships, and achieve the effect of saving debugging, reducing impact, and flexible towage form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

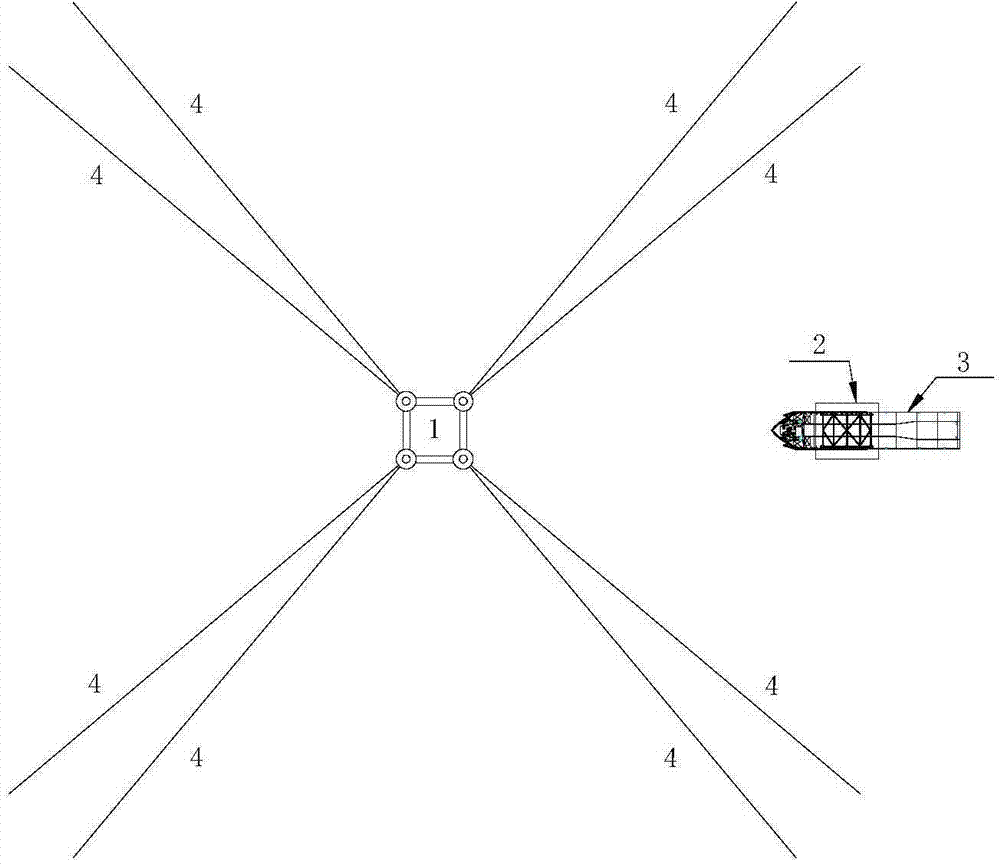

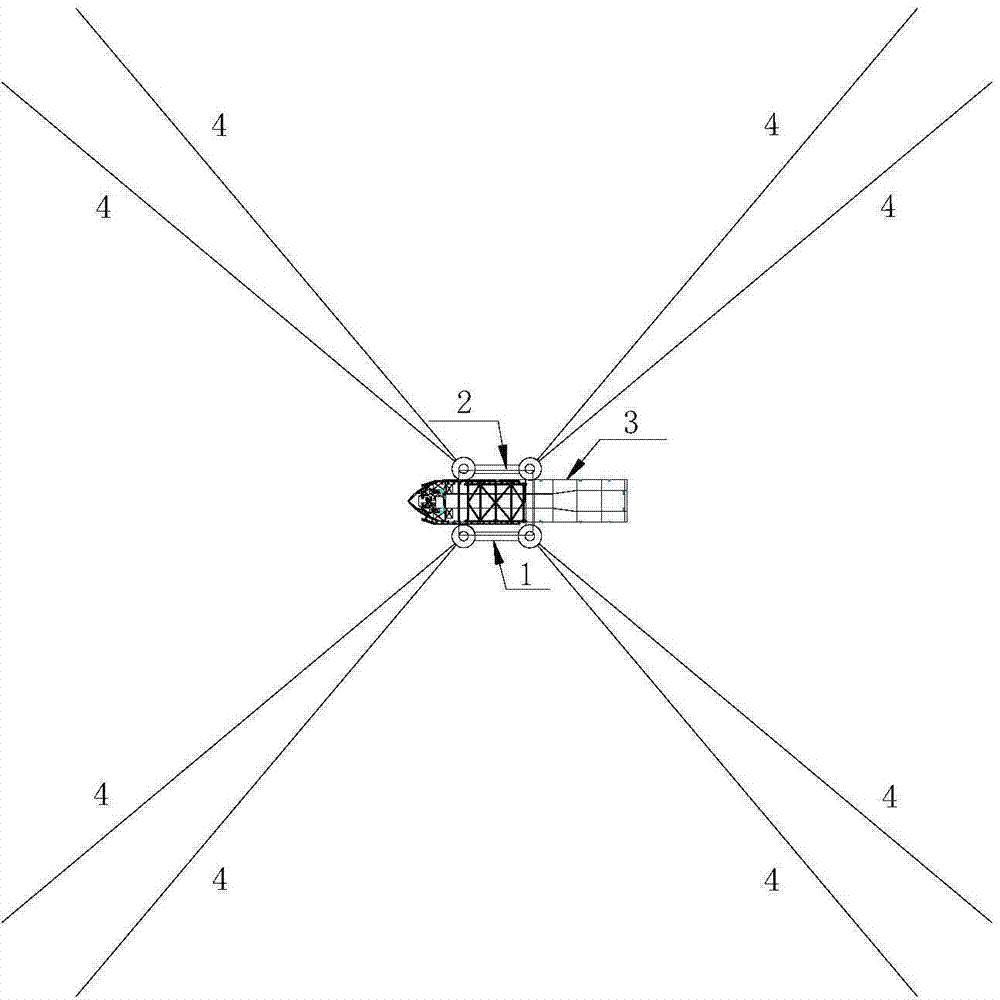

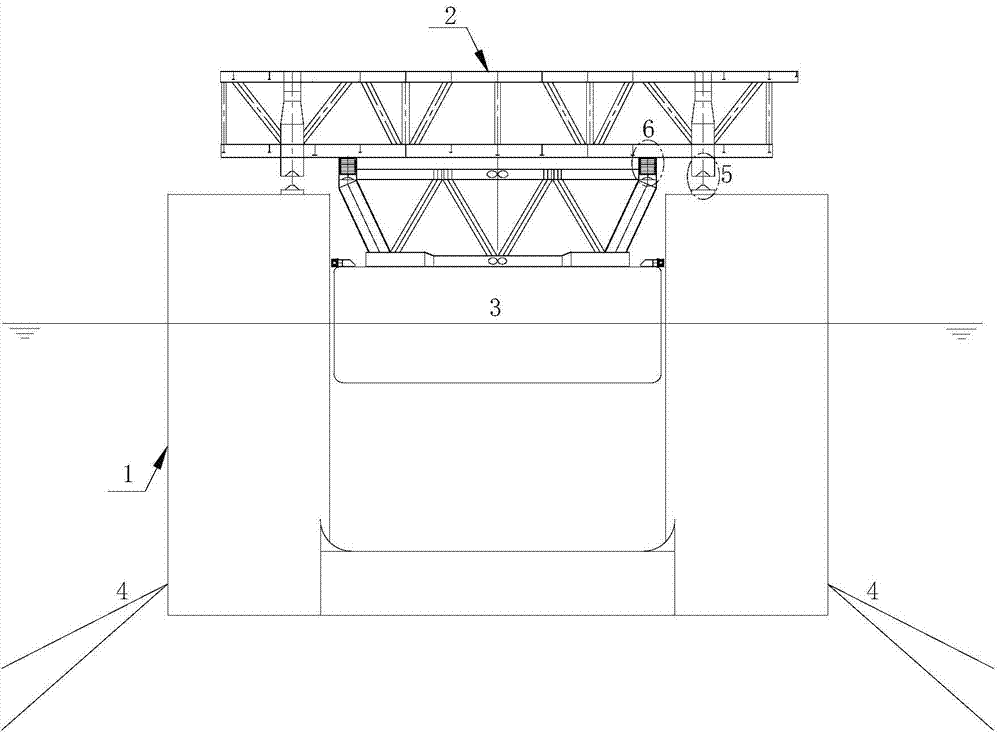

[0026] Such as figure 1 — Figure 5 As shown, the present invention adopts the following installation steps:

[0027] The first step: After the construction of the lower floating body 1 is completed, the lower floating body 1 is towed to the installation sea area with a tugboat for standby, and then connected to the columns of the lower floating body 1 through the temporary mooring system 4 and fixed; used to restrict the lower floating body 1 movement;

[0028] Step 2: Connect the upper module 2 to the dynamic positioning vessel 3 by the module support unit 6 and dry tow it to the installation sea area for standby; the position of the dynamic positioning vessel 3 from the lower floating body 1 is 300 meters away.

[0029] Step 3: Set up an environmental monitoring system on the work ship near the installation sea area to forecast the environmental conditions of the installation sea area in real time, and monitor the movement of the lower floating body 1 and the dynamic positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com