Precision control method for stay rope manufacturing

A precision control and cable technology, applied in bridge parts, bridge materials, bridges, etc., can solve the problems of inability to apply cable precision control, difficult to find marking points, etc., and achieve the effect of improving manufacturing accuracy, convenient use and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A precision control method for cable production, which is implemented sequentially according to the following steps:

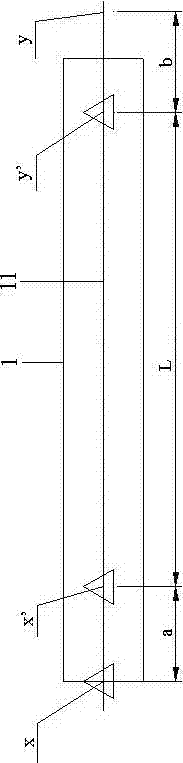

[0019] a. make the standard length steel wire 11 by the standard length of the cable steel wire, and mark the reference point and the cutting point on the standard steel wire 11, figure 2 Middle x and y are respectively the front end reference point and the rear end reference point on the standard steel wire 11, figure 2 Middle x' and y' are respectively the front end cut-off point and the rear end cut-off point on the standard steel wire 11;

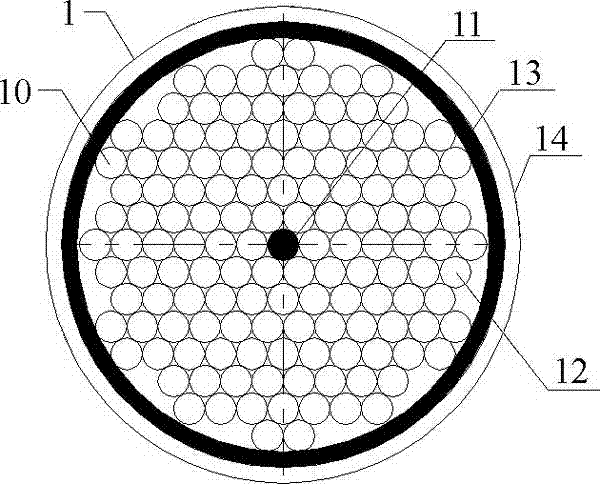

[0020] b. Weave the standard steel wire 11 into the cable strand 10, that is, continue to attach the strand steel wire 12 outside the standard steel wire 11, such as figure 1 As shown, the standard steel wire 1 is used as the central steel wire of the cable strand 10, that is, the standard steel wire 11 is located at the center of the section of other cable strand steel wires 12;

[0021] c. Twist the cable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com