A semi-automatic deviation correction and reset device for wooden frame

A reset device and semi-automatic technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of unknown force system size, skewed and flashing deformation of wooden frames, overturning of wooden frames, etc., achieving significant social and economic benefits, scientific working principle, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

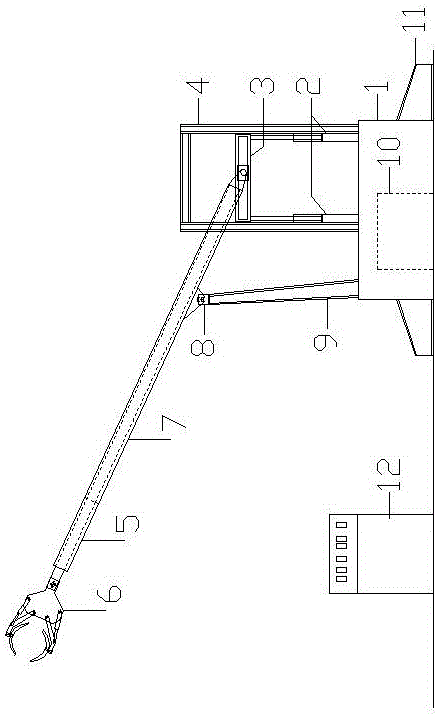

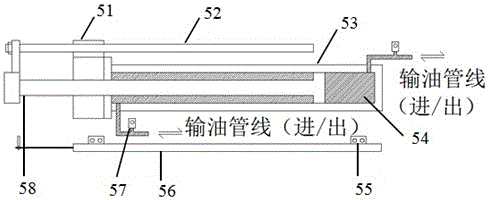

[0028] Such as figure 1 As shown in -4, a semi-automatic deviation correction and reset device for a wooden frame includes a box base 1, a machine body column 9, a reaction frame 4, a pulley device 3, a cross arm 7, a synchronous hydraulic jacking device 2, a double-acting hydraulic cylinder 5, Mechanical hoop 6, hydraulic pump station 10, control cabinet 12.

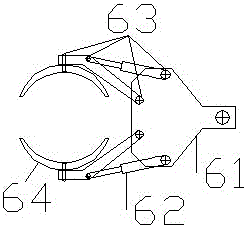

[0029] The box base 1 is equipped with a hydraulic pump station 10, and the machine body column 9 is fixed on the box body base 1. The top of the machine body column 9 is hinged to the cross arm 7 through a cross hinge 8, and the cross arm 7 is equipped with double-acting hydraulic pressure The piston rod of the oil cylinder 5, the double-acting hydraulic oil cylinder 5 extends out of the cross arm 7, and the piston rod of the double-acting hydraulic oil cylinder 5 is connected to the mechanical hoop 6 through a cylindrical pin 63; the rear end of the cross arm 7 is opposite to the block 31 in the block device 3 Articulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com