Anti-floating device for tunnel construction, steel mould board lining rig and anti-floating construction method

A technology for tunnel construction and lining of trolleys, which is applied in tunnel lining, tunnel, shaft lining and other directions, can solve problems such as low construction efficiency, heavy trolley weight, complex structure, etc., and achieves improved construction efficiency, good lining effect, and anti-floating. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further clearly and completely described in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of them.

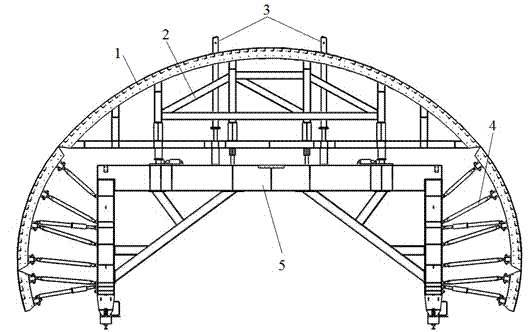

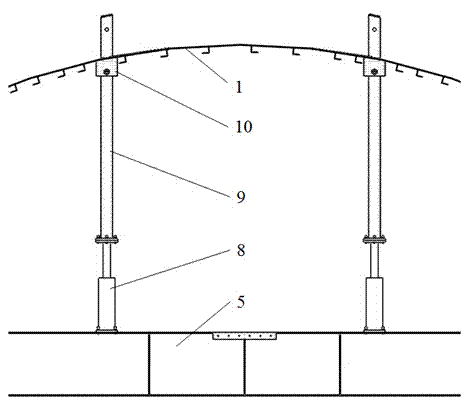

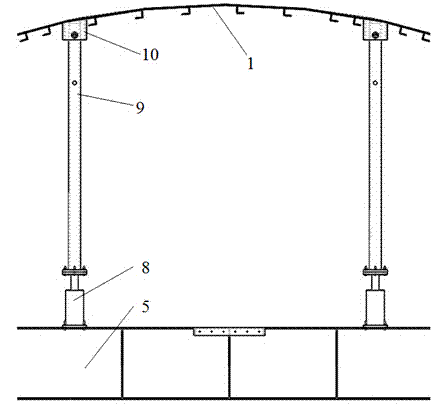

[0028] Reference attached Figure 5 , Image 6 , an anti-floating device for tunnel construction, comprising an anti-floating column 9, a lifting cylinder 8 and a limit mechanism 10, the lower end of the anti-floating column 9 is connected to the trolley door frame 5 of the steel mold lining trolley through the lifting cylinder 8, and the anti-floating column 9 The upper part is provided with a plurality of limit holes 12 in the axial direction, and the limit mechanism 10 includes a limit installation body 18 and a limit pin 16, wherein the limit installation body 18 is installed on the trolley template 1 of the steel mold lining trolley, and the limit The position mounting body 18 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com