Compressor pre-rotation control method

A compressor and pre-rotation technology, which is applied in the direction of engine control, electrical control, mechanical equipment, etc., can solve problems such as limiting the driving conditions of the compressor, and achieve the effect of increasing the maximum speed and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

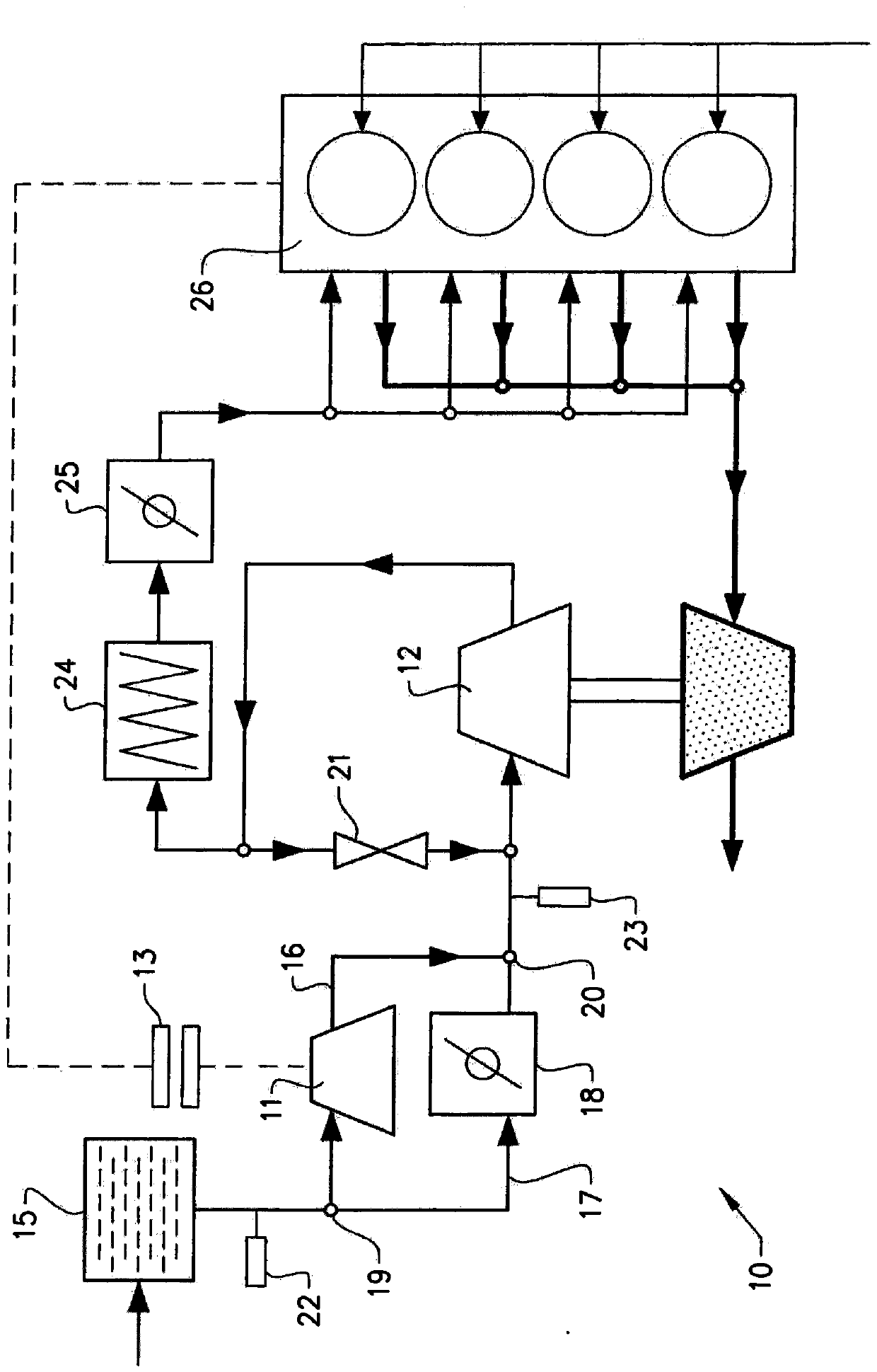

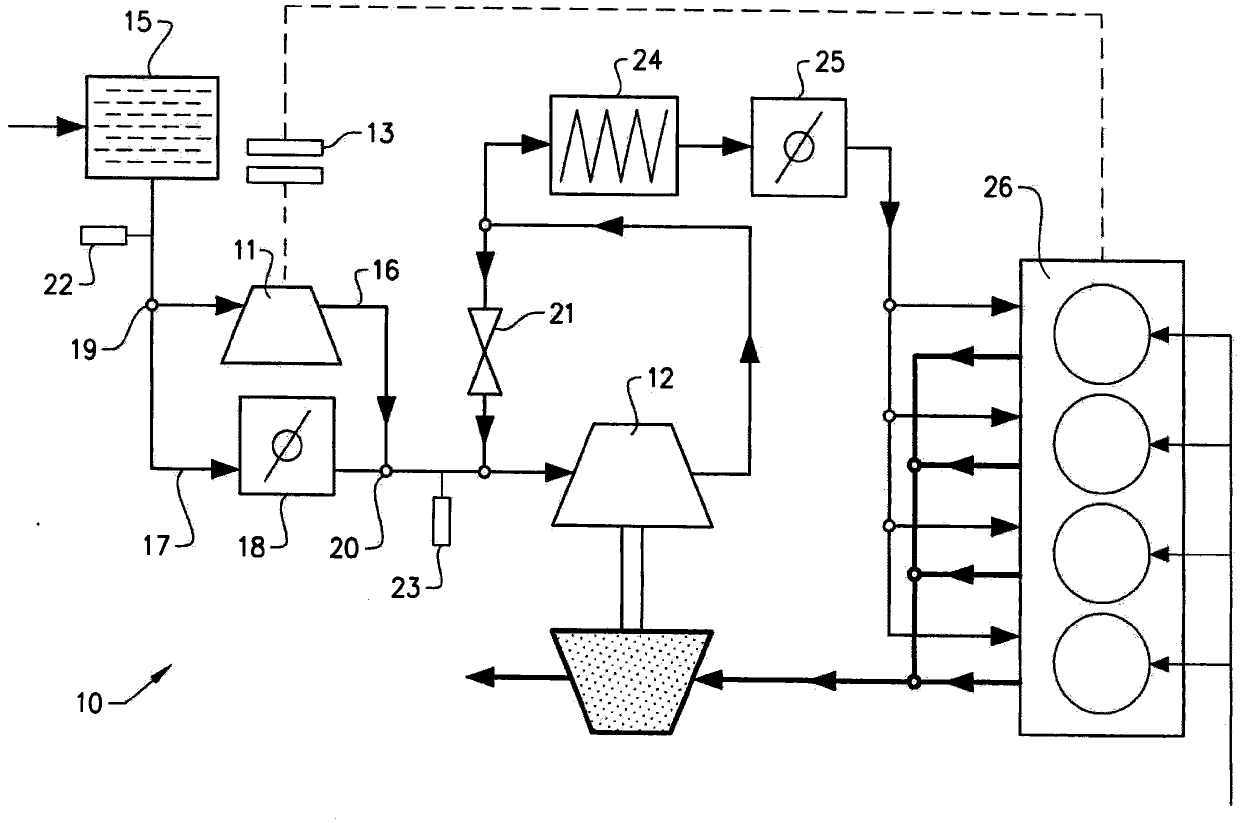

[0054] figure 1 A schematic diagram of a preferred embodiment of an internal combustion engine 10 with a compressor 11 and a turbocharger 12 is shown. The compressor 11 is connected to the crankshaft of the internal combustion engine 10 via a compressor clutch 13 . By engaging and disengaging the compressor clutch 13 , the compressor 11 can be directly or indirectly engaged and disengaged from the crankshaft of the internal combustion engine 10 , respectively. When the compressor 11 is engaged with the crankshaft of the internal combustion engine 10 , the crankshaft drives the compressor 11 . The compressor 11 increases the air pressure or air density so that more air (ie more oxygen) is supplied to the combustion chambers of the internal combustion engine 10 . The increased amount of air allows more fuel to be injected, allowing more power to be produced.

[0055] As previously stated, traditionally, when the compressor clutch is engaged, the compressor rotates significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com