Energy-saving type grain drying storehouse

A grain drying warehouse, energy-saving technology, applied in the direction of static material dryer, drying solid material, drying gas arrangement, etc., can solve the problems of poor drying uniformity, limited efficiency, difficult hot air in the central area, etc., and achieve low energy waste The effect of chemicalization and energy waste is the most

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

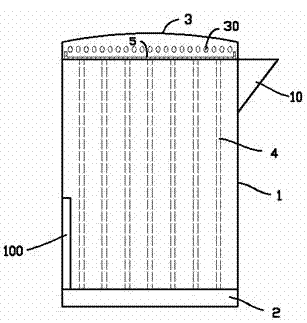

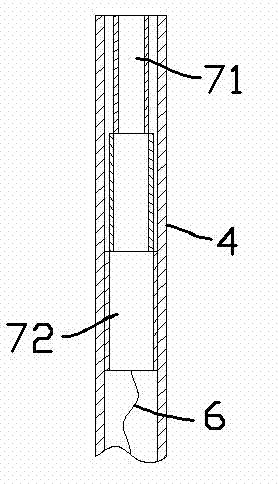

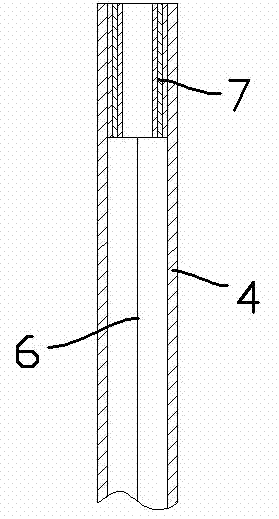

[0013] Such as figure 1 As shown, the energy-saving grain drying bin includes a bin body 1, a base 2 is provided below the bin body 1, a bin cover 3 is covered above the bin body 1, and a feed inlet 10 is provided on the upper side of the bin body 1; In the cross-section surrounded by the warehouse body 1, there are evenly distributed vertically extending heat pipes 4, and the peripheral walls of the heat pipes 4 are evenly distributed with pores that can block grains, that is, the surrounding walls of the heat pipes are ventilated, but it is not allowed The grains enter the heat pipe; the heat pipe 4 is provided with a heating device; one end of the heat pipe 4 extends to the base 2 and communicates with the outside world, and the other end extends to the warehouse body 1 and the warehouse cover 3 The surface of the net plate at the joint; the periphery of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com