Anti-seismic and leak-proof structural temperature sensor

A temperature sensor and leakage resistance technology, applied in thermometers, thermometer parts, instruments, etc., can solve problems such as unsatisfactory use effect, instability, sensor damage, etc., and achieve excellent shock resistance and leakage resistance, service life and measurement accuracy. Guarantee and increase the effect of sealing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

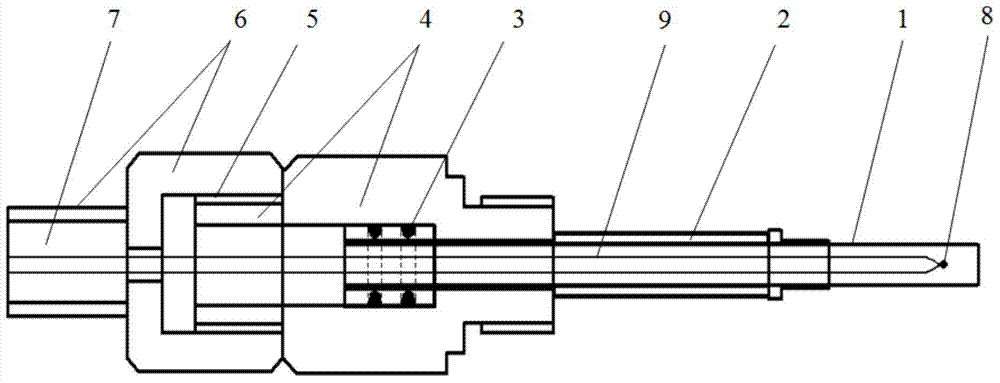

[0022] Such as figure 1 As shown, a temperature sensor with an anti-seismic and leak-proof structure, starting from the head of the temperature sensor, sequentially includes: an armored fixed sleeve 1, and the armored fixed sleeve 1 has a temperature-sensing element inside, and the temperature-sensing element includes a temperature-sensing probe 8 and the probe connecting wire 9, the probe connecting wire 9 has been connected to the junction box at the end of the temperature sensor (not shown in the figure); connected to the lower nut 4 of the armored fixing sleeve 1, the armored fixing sleeve The tube 1 can reciprocate in the lower nut 4 in the form of a piston; the upper nut 6 connected with the lower nut 4, the tail of the upper nut 6 is a hollow structure, which can be connected to a junction box or other structures as required; the armored fixing sleeve The pipe 1 is equipped with an elastic connector, and the lower nut 4 is provided with a sealing ring 3 inside which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com