Optical axis orientation consistency detection system and method of corner reflector or corner reflector array

A corner reflector and optical axis pointing technology, applied in the field of optical testing, can solve problems such as no public reports, inconsistent brightness and size of corner reflector arrays, and no special device or method for testing optical axis consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

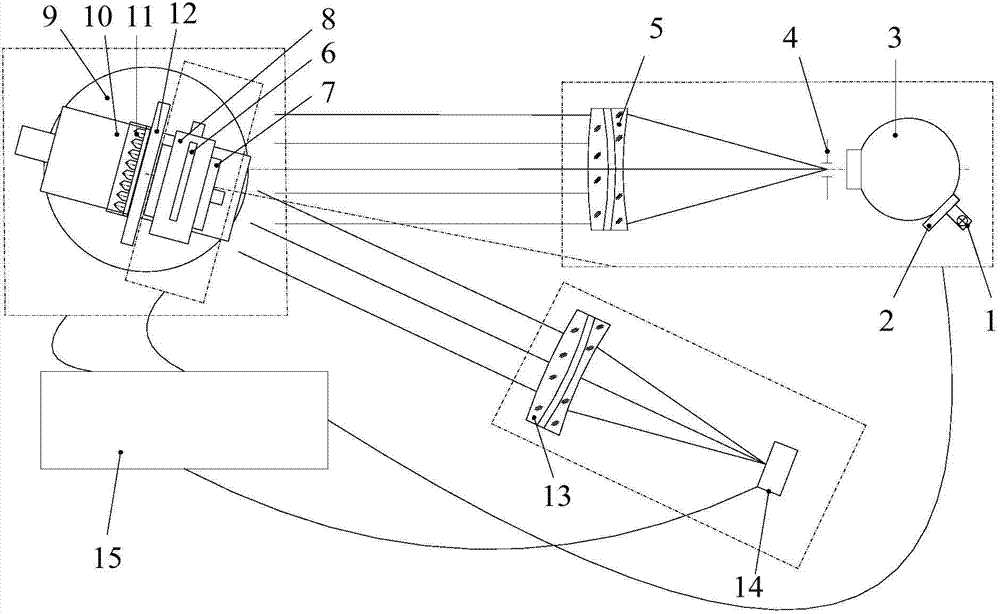

[0045] see figure 1 , the present invention provides a corner reflector or a corner reflector array optical axis pointing consistency detection system (abbreviation: detection system), which includes a collimated light source unit, a liquid crystal light valve dynamic diaphragm unit, and a corner reflector attitude adjustment unit , CCD measurement unit and control unit 15; the liquid crystal light valve dynamic diaphragm unit is arranged on the outgoing light path of the collimated light source unit; the corner reflector attitude adjustment unit is arranged on the outgoing light path of the liquid crystal light valve dynamic diaphragm unit; the measured angle The reflector or corner reflector array 11 is arranged on the corner reflector attitude adjustment unit; the CCD measurement unit is arranged on the optical path where the reflected light reflected by the measured corner reflector or corner reflector array is located; the control unit 15 is respectively connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com