Combined type ultrasonic-eddy current detection probe clamping structure

A technology of eddy current detection probe and clamping structure, which is applied in the direction of material analysis, measuring devices and instruments using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as probe layout restrictions and achieve the effect of preventing water overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

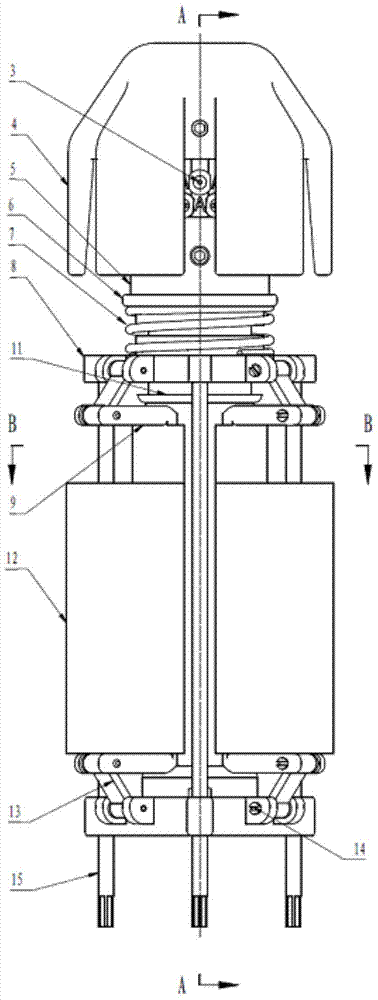

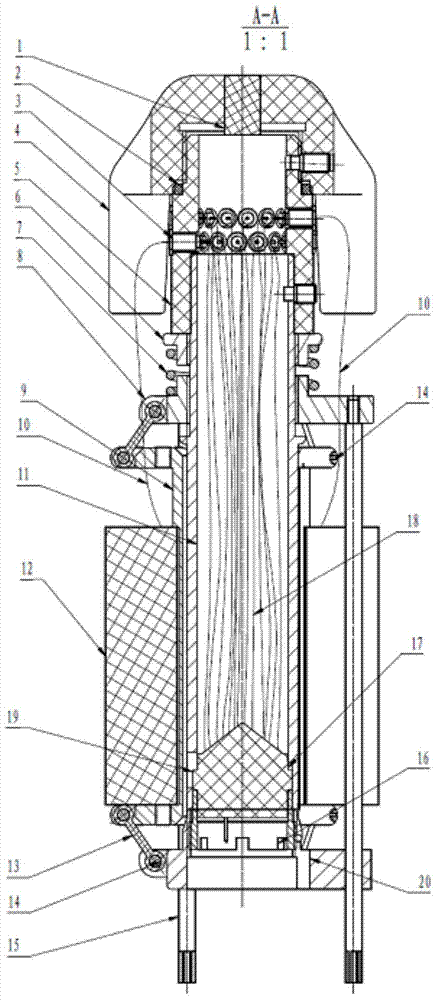

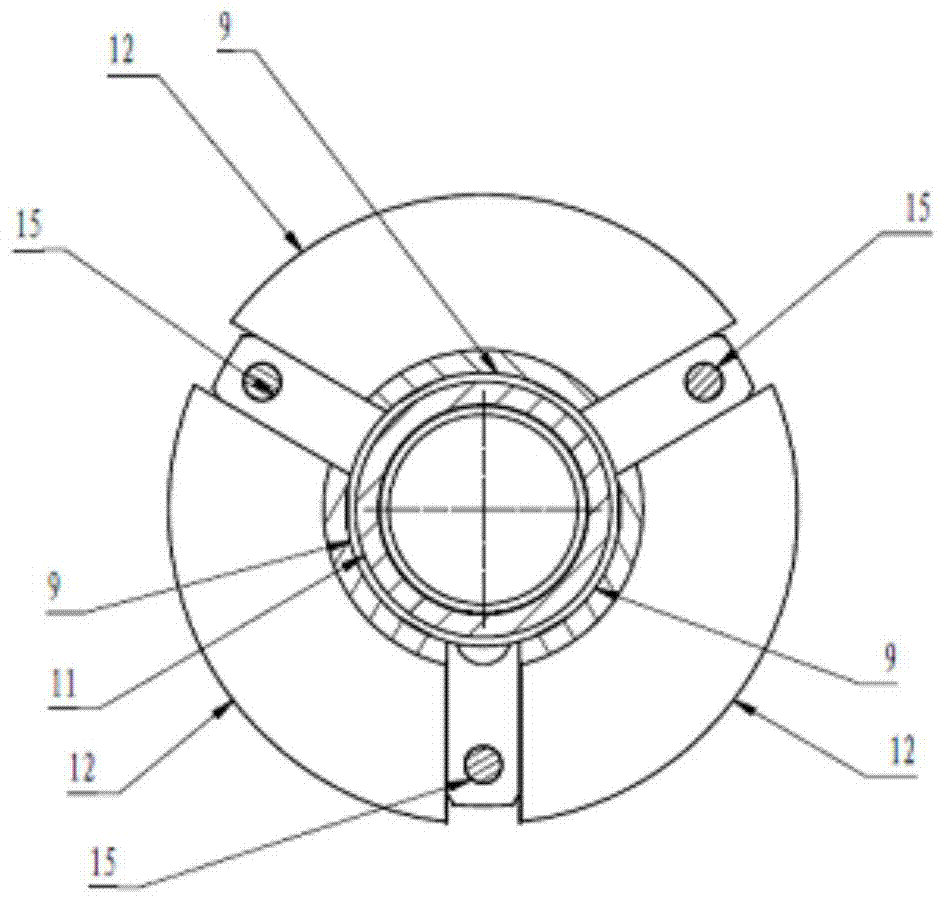

[0027] A combined ultrasonic-eddy current detection probe clamping structure, its structure is as follows figure 1 As shown, it includes a base structure and a probe-driven four-bar mechanism. The probe-driven four-bar mechanism includes a compression spring nut 6, a compression spring 7, an upper compression ring 8, a probe liner 9, a core tube 11, a new combination probe 12, and a connecting rod. Rod 13, rotating shaft pin 14, ejector rod 15 and base 20;

[0028] The core tube 11 is cylindrical, and the compression spring nut 6, the compression spring 7, and the upper pressure ring 8 are sequentially set on the outside of the core tube 11 from top to bottom, and the compression spring nut 6 has an internal thread, which is connected to the core tube 11 through the thread;

[0029] The probe liner 9 is located below the upper pressure ring 8 and inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com