Vacuum tower online monitoring method based on fuzzy process capacity of kernel function

A technology of fuzzy process capability and process capability, applied in electrical digital data processing, electrical testing/monitoring, special data processing applications, etc., can solve the evaluation, the complex interaction relationship, the volatility of the production data of vacuum tower distillation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

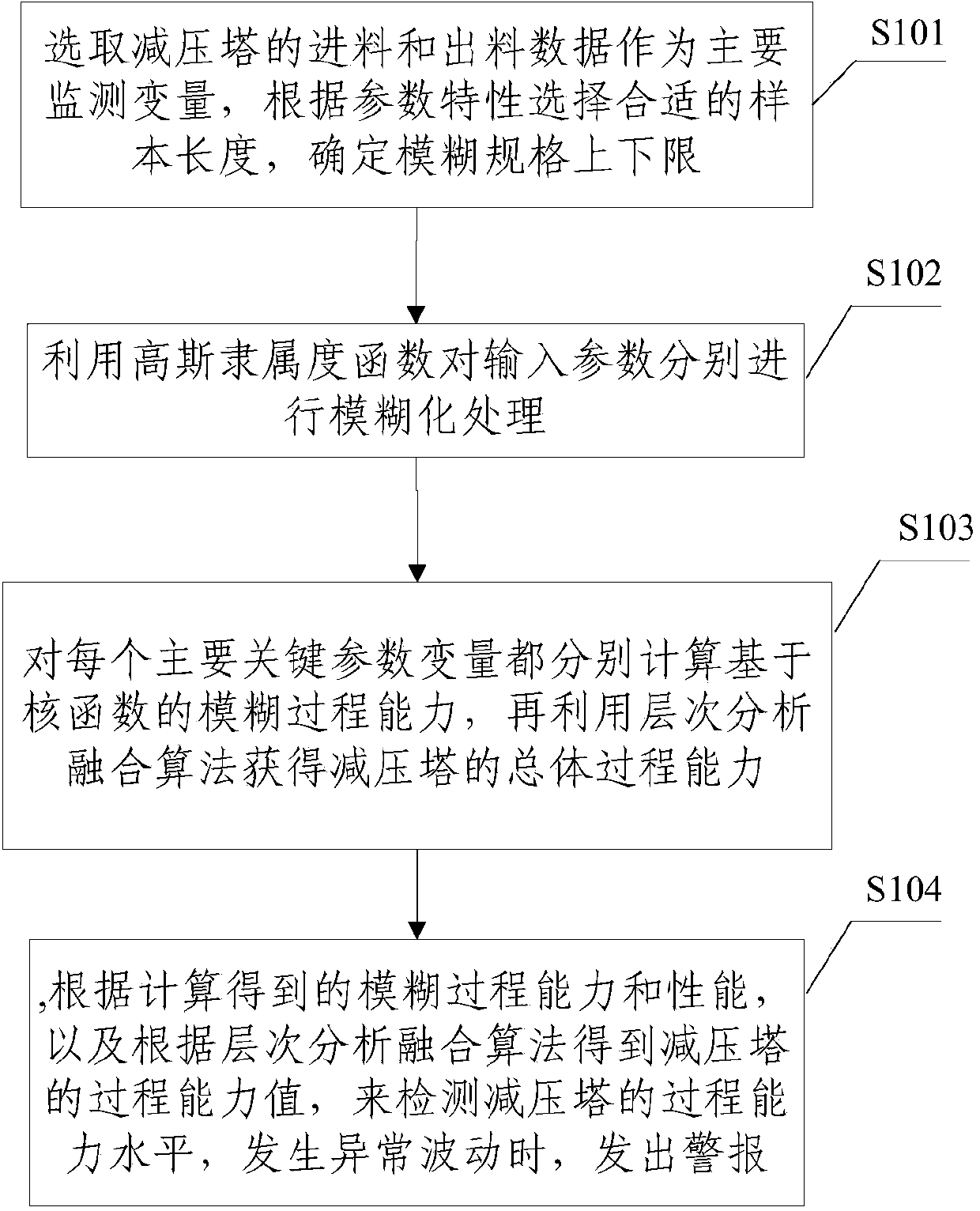

[0049]The vacuum tower on-line monitoring method based on the fuzzy process capability of kernel function of the present invention comprises the following steps:

[0050] S101, selecting the main input and output parameters of the process flow of the vacuum tower as monitoring variables, selecting an appropriate sample length according to the characteristics of the parameters, and determining the upper and lower limits of fuzzy specifications;

[0051] In actual operation, you can choose to collect data in real time from the OPC server, select the feed parameter variable FICA-11401, FICA-11402, FICA-11405, FICA-11406 of the vacuum tower process flow, and the discharge para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com