Fabric defect detection method based on B-spline wavelets and deep neural network

A spline wavelet and defect technology, applied in biological neural network models, image data processing, instruments, etc., can solve problems such as manual intervention of different background patterns, slow calculation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

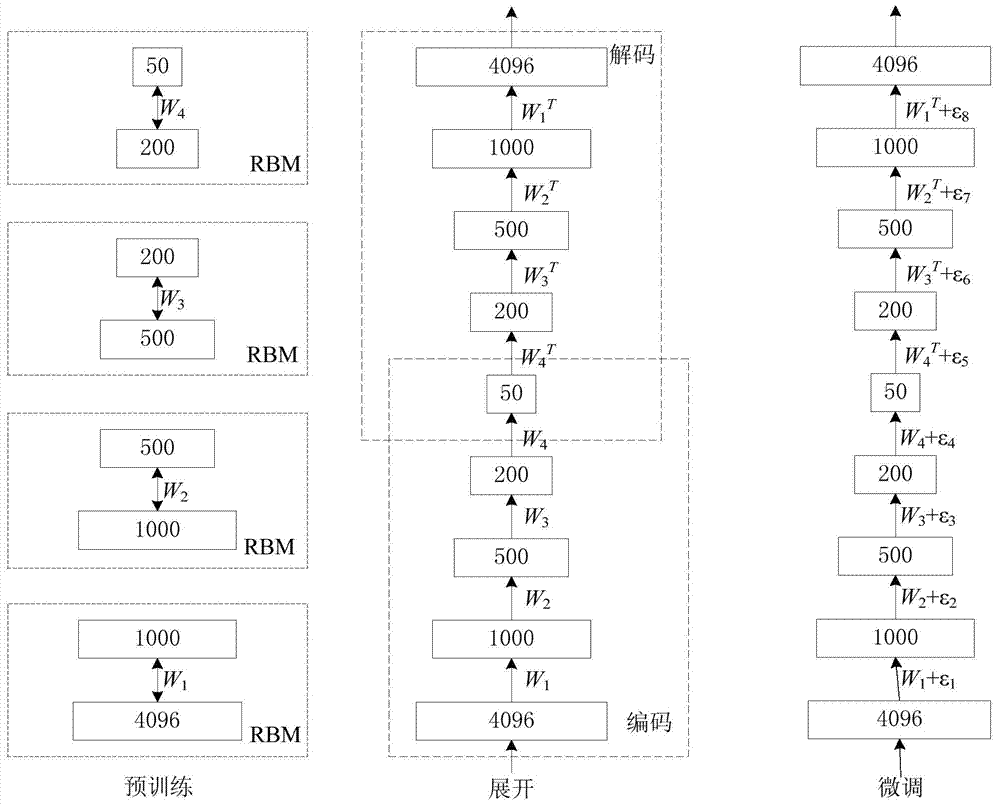

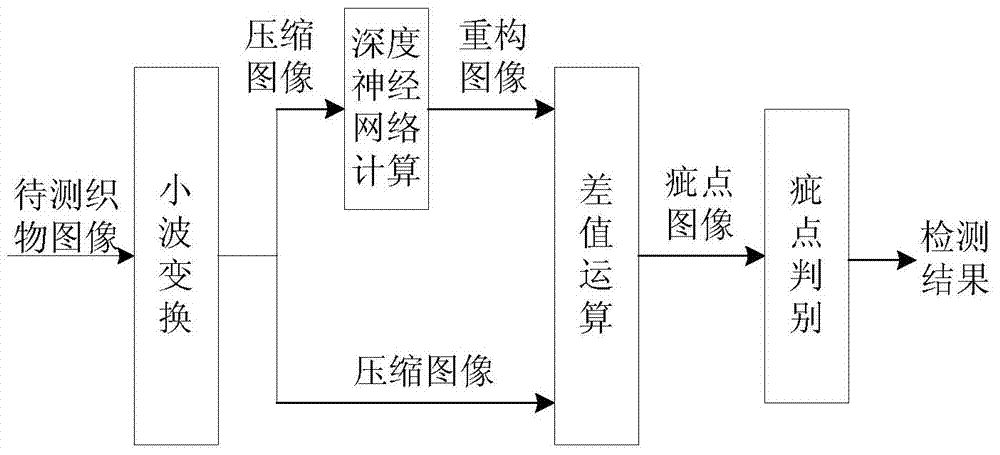

[0064] An automatic detection method for fabric defects includes two steps: a model training stage and a detection stage.

[0065] Step 1, the model training stage has the following implementation steps:

[0066] 11. Expand the length and width pixels of the image in the sample library to 2 n The square, the extended part is filled with 0;

[0067] 12. Perform multiple B-spline wavelet transforms on the image, the specific implementation is as follows:

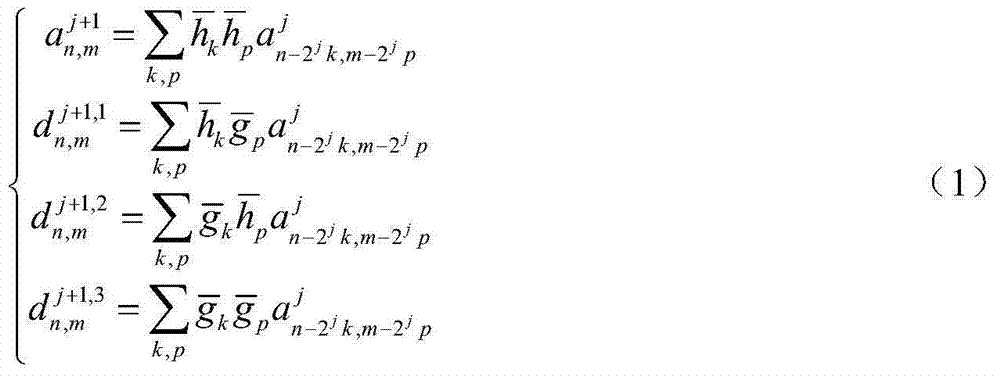

[0068] 12.1 Carry out B-spline wavelet transform on the image to obtain four images of diagonal direction sub-image HH, vertical direction sub-image HL, horizontal direction sub-image LH and low-frequency sub-image LL. The fast wavelet transform algorithm is shown in formula (1):

[0069] a n , m j + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com