Electric fuse structure

A technology of electric fuses and fuses, applied in circuits, electrical components, electric solid devices, etc., can solve the inconvenience of circuit designers and the inability to obtain constant resistance value changes, etc., and achieve the effect of flexible circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

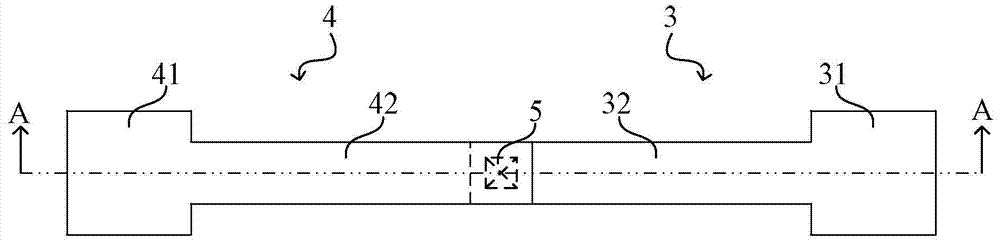

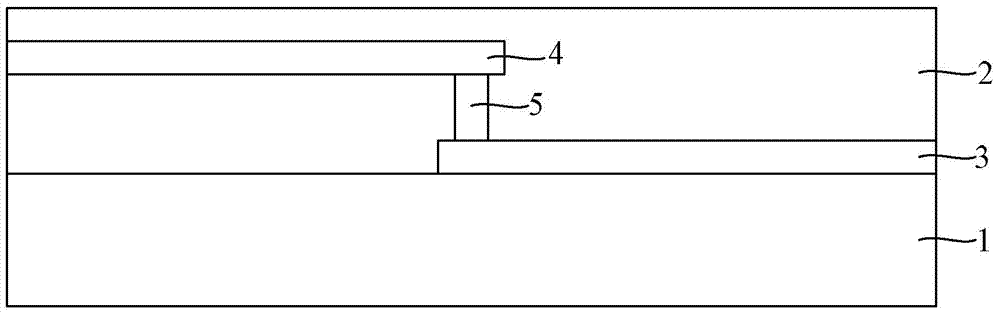

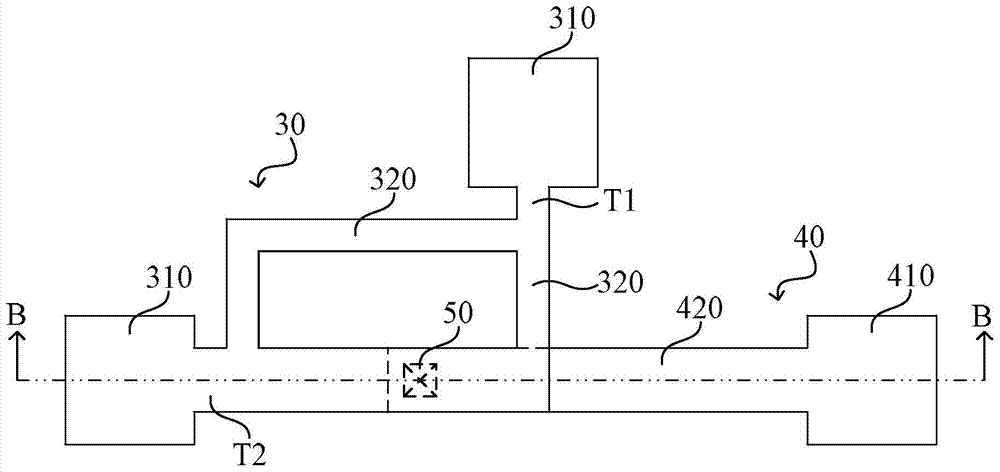

[0038] It can be seen from the foregoing that the existing electric fuse structure has only two electrodes, namely an anode and a cathode, and the two electrodes are electrically connected through a conductive plug. According to the fusing mechanism of the electric fuse structure, when the electric fuse structure is blown, the position of the conductive plug will be blown, so that a constant resistance value cannot be measured at the two electrodes after the electric fuse structure is blown.

[0039] In view of this, the present invention proposes an improved electric fuse structure, by arranging a first electric fuse unit including a plurality of first fuses in the first conductive pattern layer of the electric fuse structure, and at least one first A first fuse of an electric fuse unit is electrically connected with the conductive plug, so that when the electric fuse structure is blown, although the position of the conductive plug will be blown, so that after the electric fus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com