Cathode material for high-capacity graphene lithium sulphur battery and preparation method of cathode material

A positive electrode material, lithium-sulfur battery technology, applied in the field of electrochemical applications, can solve the problems of reducing ohmic resistance, poor adhesion between slurry and current collector, etc., to reduce ohmic resistance and solve poor adhesion , the effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] One coat:

[0021] (1) Add 0.1g of PVDF (polyvinylidene fluoride) to 1.15g of NMP (N-methylpyrrolidone), keep the temperature at 40°C, and magnetically stir for 4 hours to form a PVDF solution.

[0022] (2) Add 0.9g graphene to 4.5g NMP, stir magnetically for 6 hours, put it into an ultrasonic oscillator with an ultrasonic power of about 100 W, and oscillate ultrasonically for 1 hour, then add 1.25g PVDF solution and an appropriate amount of NMP to adjust the slurry Viscosity, continued magnetic stirring for 2 hours, coated the prepared slurry on aluminum foil by casting method, and dried it in a vacuum oven at 120°C for 2 hours to obtain a graphene-coated aluminum foil current collector. The number of graphene sheets used is 4-7 layers, with good crystallinity and a specific surface area of about 380 m 2 / g, the electrical conductivity is about 3520 S / m, and the thickness of the graphene coating is 4 μm.

[0023] Secondary coating:

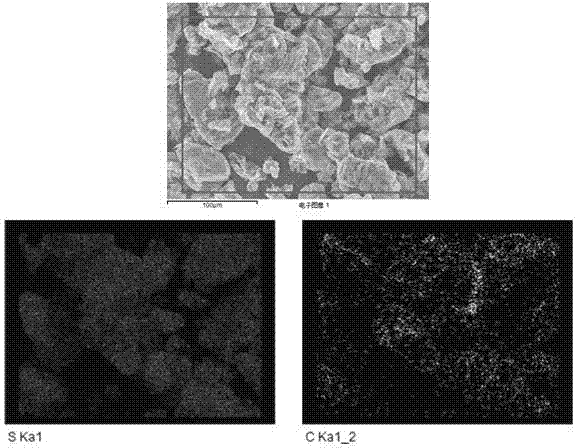

[0024] (1) Mix graphene an...

Embodiment 2

[0029] One coat:

[0030] (1) Add 0.1g of PVDF to 1.15g of NMP, keep the temperature at 40°C, and magnetically stir for 4h to form a PVDF solution.

[0031] (2) Add 0.9g graphene to 4.5g NMP, stir magnetically for 6 hours, put it into an ultrasonic oscillator with an ultrasonic power of about 100 W, and oscillate ultrasonically for 1 hour, then add 1.25g PVDF solution and an appropriate amount of NMP to adjust the slurry Viscosity, continued magnetic stirring for 2 hours, coated the prepared slurry on aluminum foil by casting method, and dried it in a vacuum oven at 120°C for 2 hours to obtain a graphene-coated aluminum foil current collector. The number of graphene sheets used is 4-7 layers, with good crystallinity and a specific surface area of about 380 m 2 / g, the electrical conductivity is about 3520 S / m, and the thickness of the graphene coating is 4 μm.

[0032] Secondary coating:

[0033](1) Mix graphene and sublimed sulfur evenly in a mixer at a mass ratio of 1...

Embodiment 3

[0038] One coat:

[0039] (1) Add 0.1g of PVDF (polyvinylidene fluoride) to 1.15g of NMP (N-methylpyrrolidone), keep the temperature at 40°C, and magnetically stir for 4 hours to form a PVDF solution.

[0040] (2) Add 0.9g graphene to 4.5g NMP, stir magnetically for 6 hours, put it into an ultrasonic oscillator with an ultrasonic power of about 100 W, and oscillate ultrasonically for 1 hour, then add 1.25g PVDF solution and an appropriate amount of NMP to adjust the slurry Viscosity, continued magnetic stirring for 2 hours, coated the prepared slurry on aluminum foil by casting method, and dried it in a vacuum oven at 120°C for 2 hours to obtain a graphene-coated aluminum foil current collector. The number of graphene sheets used is 4-7 layers, with good crystallinity and a specific surface area of about 380 m 2 / g, the electrical conductivity is about 3520 S / m, and the thickness of the graphene coating is 8 μm.

[0041] Secondary coating:

[0042] (1) Mix graphene and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com