Combined type brushless direct-current permanent magnet magnetic flow switching motor and axial proportion calculation method

A magnetic flux switching motor, combined technology, applied in electrical components, electromechanical devices, etc., can solve the problems of narrow speed range, poor field weakening ability of brushless DC motors, etc., achieves low risk of demagnetization, easy speed sensorless technology, Control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

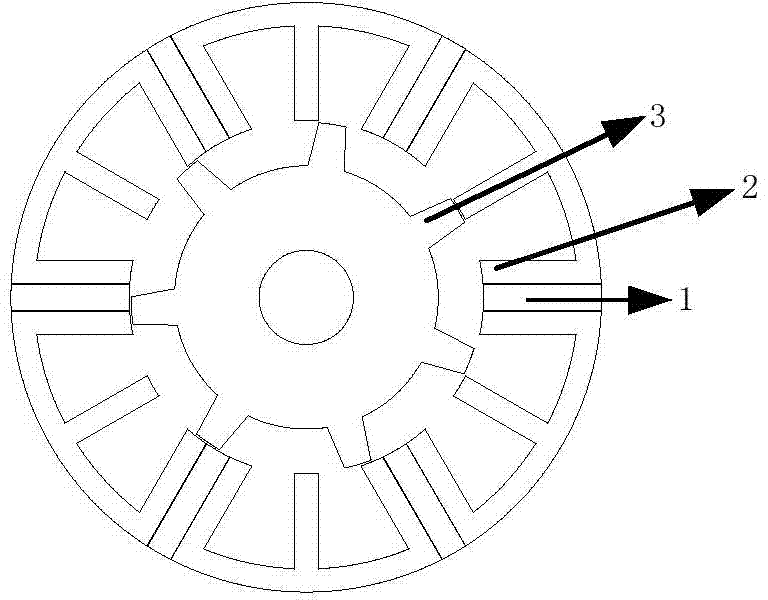

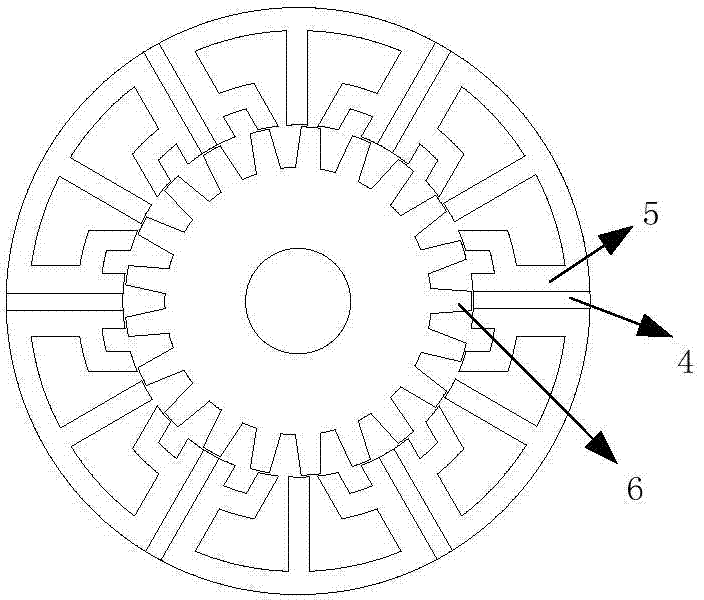

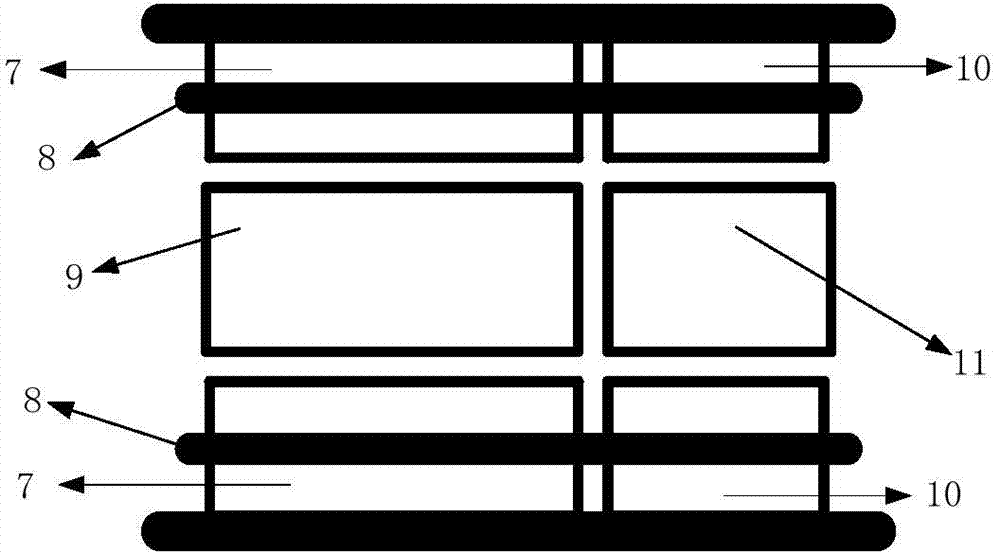

[0041] In the first embodiment, the stator core of the first motor and the stator core of the second motor are both 6-tooth structures, the number of teeth of the first rotor is 7, and the number of teeth of the second rotor is 21 as an example to further illustrate the technical solution of the present invention:

[0042] The excitation direction of the excitation source on the stator teeth of the stator of the first motor and the stator of the second motor can be the same or opposite. The first motor and the second motor are separated by a magnetic isolation material; The first rotor teeth of the second motor rotor are staggered by a rotor offset angle, the offset angle is An integer multiple of.

[0043] In the combined brushless DC permanent magnetic flux switching motor, if the stator of the first motor and the stator of the second motor have the same stator teeth, the excitation direction of the excitation source is the same, then the first rotor tooth of the first motor roto...

Embodiment 2

[0069] The second embodiment is a 6 / 5C iron core permanent magnetic flux switching motor and a 6 / 15 multi-tooth fault-tolerant permanent magnetic flux switching motor. Among them, 6 / 5C iron core permanent magnetic flux switching motors such as Figure 7 As shown, the 6 / 15 multi-tooth fault-tolerant permanent magnetic flux switching motor is as Figure 8 Shown. Figure 7 with Figure 8

Embodiment 3

[0070] The third embodiment is a 6 / 8C iron core permanent magnetic flux switching motor and a 6 / 24 multi-tooth fault-tolerant permanent magnetic flux switching motor. Among them, the 6 / 8C iron core permanent magnetic flux switching motor such as Picture 9 As shown, the 6 / 24 multi-tooth fault-tolerant permanent magnetic flux switching motor is as Picture 10 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com