Current effective value minimizing control method for bidirectional half-bridge tri-level DC (Direct Current)-DC converter

A DC-DC, half-bridge three-level technology, applied in the direction of converting DC power input to DC power output, adjusting electrical variables, control/regulation systems, etc., can solve the problems of reducing converter efficiency, increasing circulating power and current stress, Issues such as increased switching device and magnetic component losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

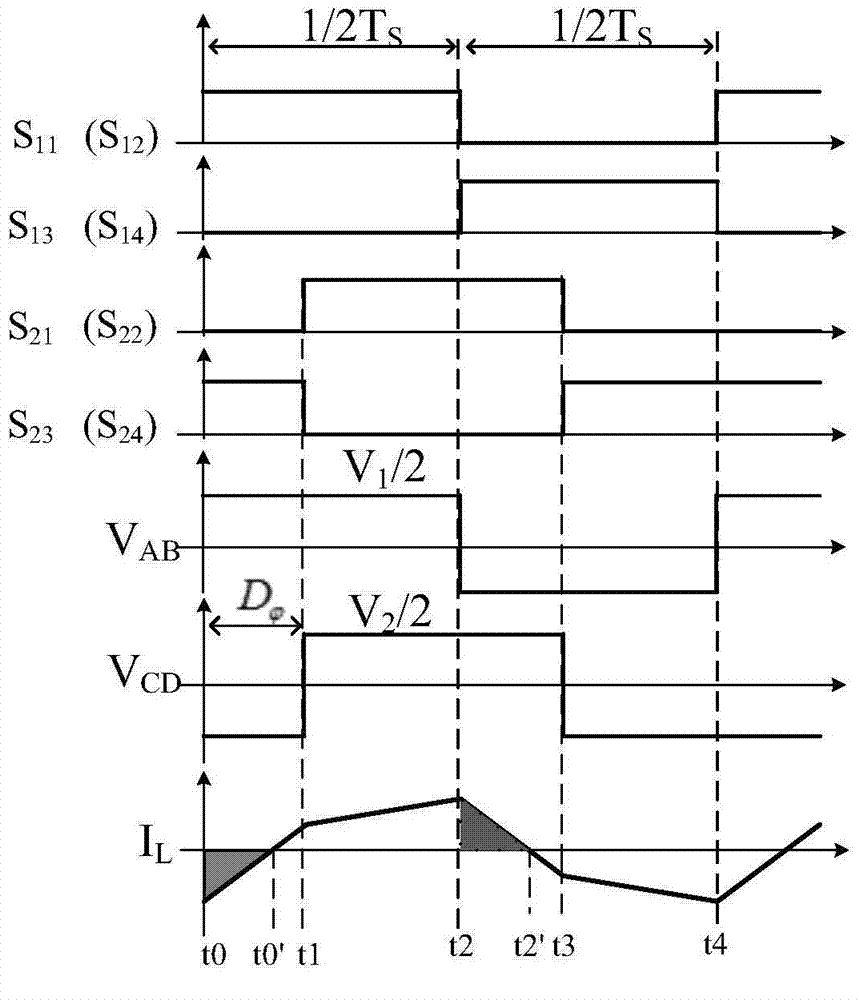

[0055] According to the analysis steps of the control method provided in the Summary of the Invention part and the D that meets the control target provided by Table 1 1 、D 2 about the expression of Figure 5 When k=0.3, 0.5, 0.7, 0.9, D 1 、D 2 about control curve. The controller implements the specific implementation of the optimal control method proposed in this patent as Figure 7 Shown:

[0056] a) The voltage control module of the controller controls the load side voltage (V 2 ) and reference voltage (V 2ref ) error for feedback control, get shift phase

[0057] b), read in the result of a), and obtain the duty ratio D of the primary side bridge arm voltage according to Table 1 1 and the duty cycle of the secondary arm voltage D 2 :

[0058] when in the range of hour,

[0059] when in the range of hour,

[0060]

[0061] when in the range of when D 1 = 1, D 2 = 1;

[0062] c), the step a), b) obtained D. 1 and D 2 The input switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com