Calibration method of camera optical axis detection apparatus

A technology of detection equipment and calibration method, which is applied in the field of calibration, can solve problems such as large investment, and achieve the effect of simple operation, cost saving, and accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Place the camera on the optical axis detection device according to the test position, and take a screenshot of the image mapped by the camera at this time.

[0028] 2. Open the picture with drawing software, and read the center coordinate value (316, 245).

[0029] 3. Rotate the camera 180 degrees based on the original test position, and take a screenshot of the image mapped by the camera at this time.

[0030] 4. Open the picture with drawing software, and read the center coordinate value (326, 237).

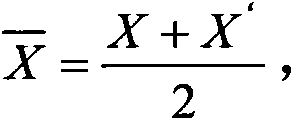

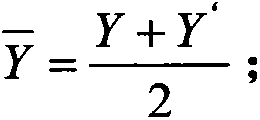

[0031] 5. Calculate: X ‾ = 316 + 326 2 = 321 , Y ‾ = 245 + 237 2 = 241 , That is, the central value (321, 241) is obtained.

[0032] 6. Calcu...

Embodiment 2

[0040] 1. Place the camera on the optical axis detection device according to the test position, and take a screenshot of the image mapped by the camera at this time.

[0041] 2. Open the picture with drawing software and read the center coordinates (X, Y).

[0042] 3. Rotate the camera 180 degrees based on the original test position, and take a screenshot of the image mapped by the camera at this time.

[0043] 4. Open the picture with drawing software and read the center coordinates (X′, Y′).

[0044] 5. Do a parallel experiment, that is, repeat steps 1 to 4 ten times, so as to avoid the occurrence of a single error that is too large. The obtained data are shown in the table below.

[0045]

X

Y

X′

Y′

1

316.423

242.626

321.223

238.366

2

316.625

242.571

321.561

238.424

3

316.228

242.213

321.419

238.667

4

315.986

242.531

321.549

238.129

5

316.352

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com