Machine for grinding buttons

A technology for machines and buttons, applied in the direction of buttons, applications, grinding machines, etc., which can solve the problems of inoperability, and the adaptation of disc-shaped elements is not particularly fast and precise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

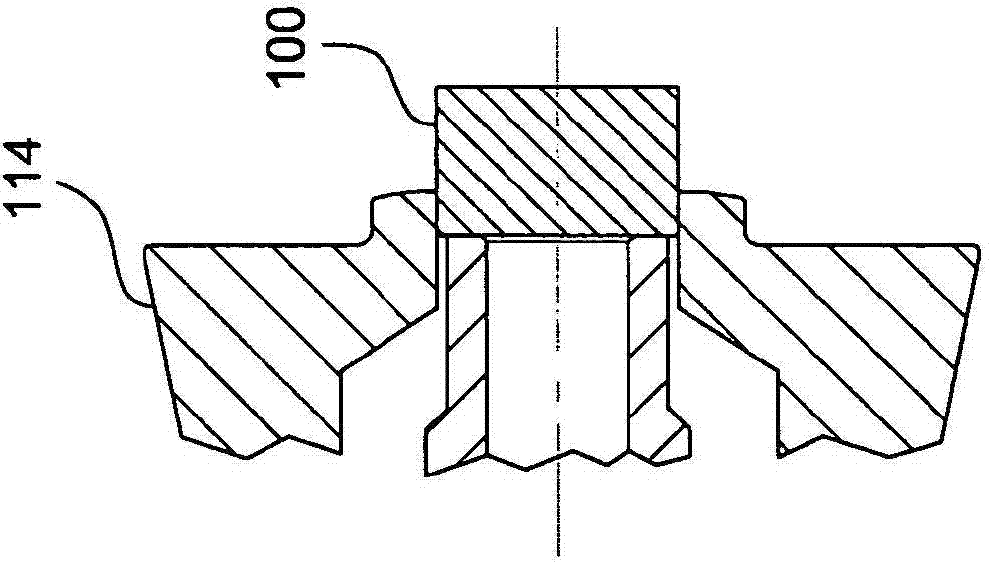

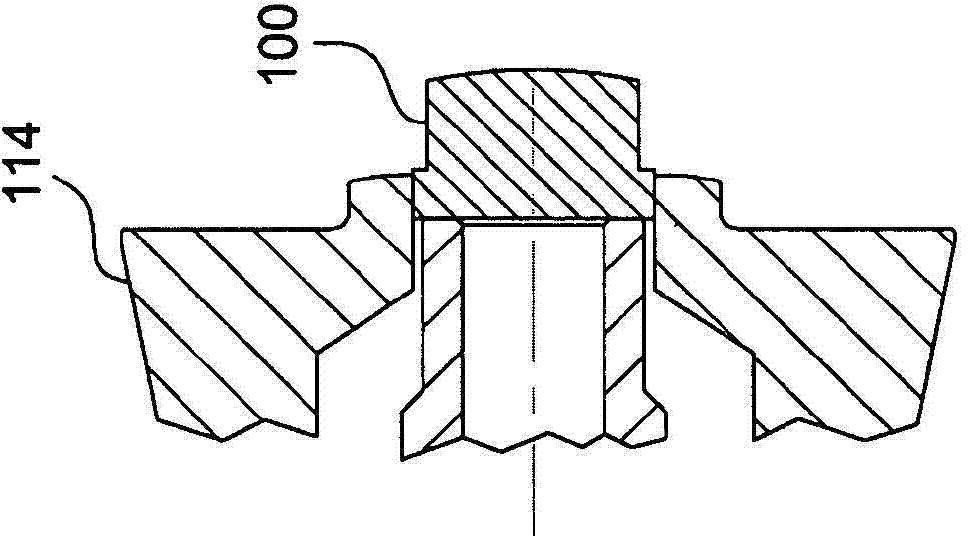

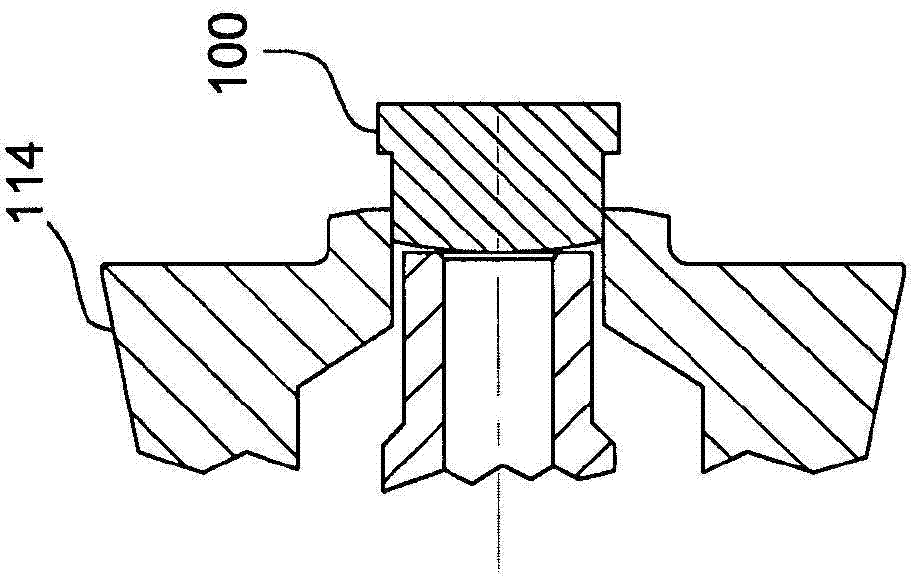

[0039] special reference Figures 3 to 12 , these figures show a first embodiment of a machine for manufacturing buttons according to the invention, which machine is generally designated by the reference numeral 10 .

[0040] The machine 10 firstly comprises a base 12 on which all the processing units of the machine 10 itself are supported. It is of particular importance that known hopper-type container means 14 are supported on the base 12 for the plurality of disc-shaped elements 100 which must be ground before their final transformation into buttons.

[0041]A feeding device 16 is operatively connected to the container device 14, which feed device 16 selectively feeds the disc-like elements 100 one at a time to the clamp holding device 18 by dropping through a spring channel (not shown). A jig holding device 18 fixed to the base 12 is capable of holding and rotating the single disc-shaped element 100, while a processing device 20, also fixed to the base 12 and arranged adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com