Plastic coating production equipment and production method thereof

A technology of production equipment and production method, which is applied in the field of plastic processing, can solve problems such as cost increase, yield decrease, workpiece scratches, etc., and achieve the effects of cost saving, easy operation, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

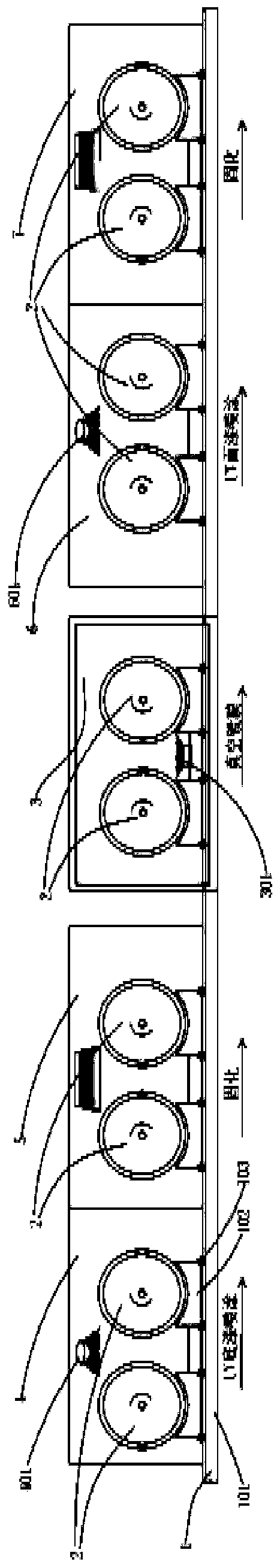

Method used

Image

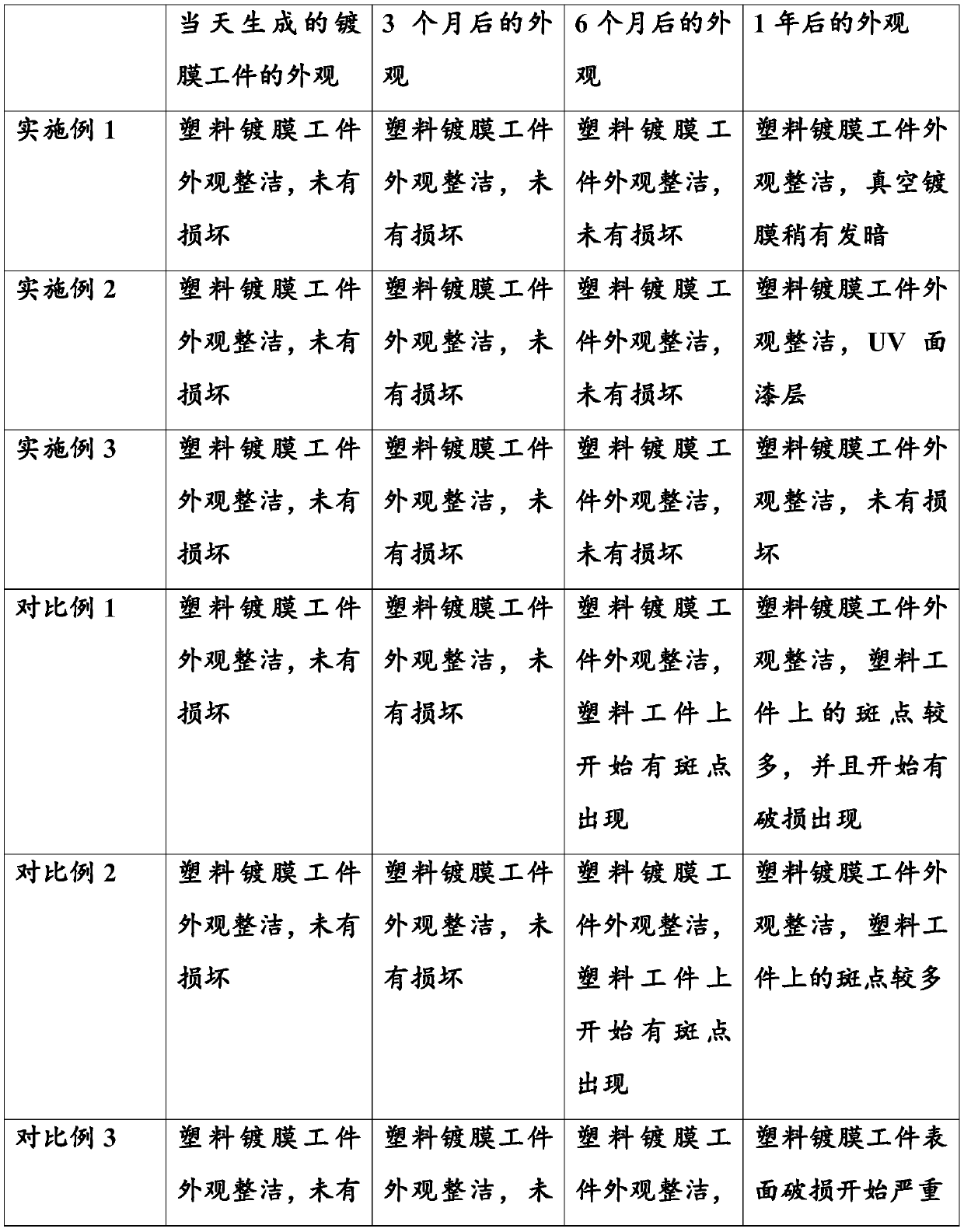

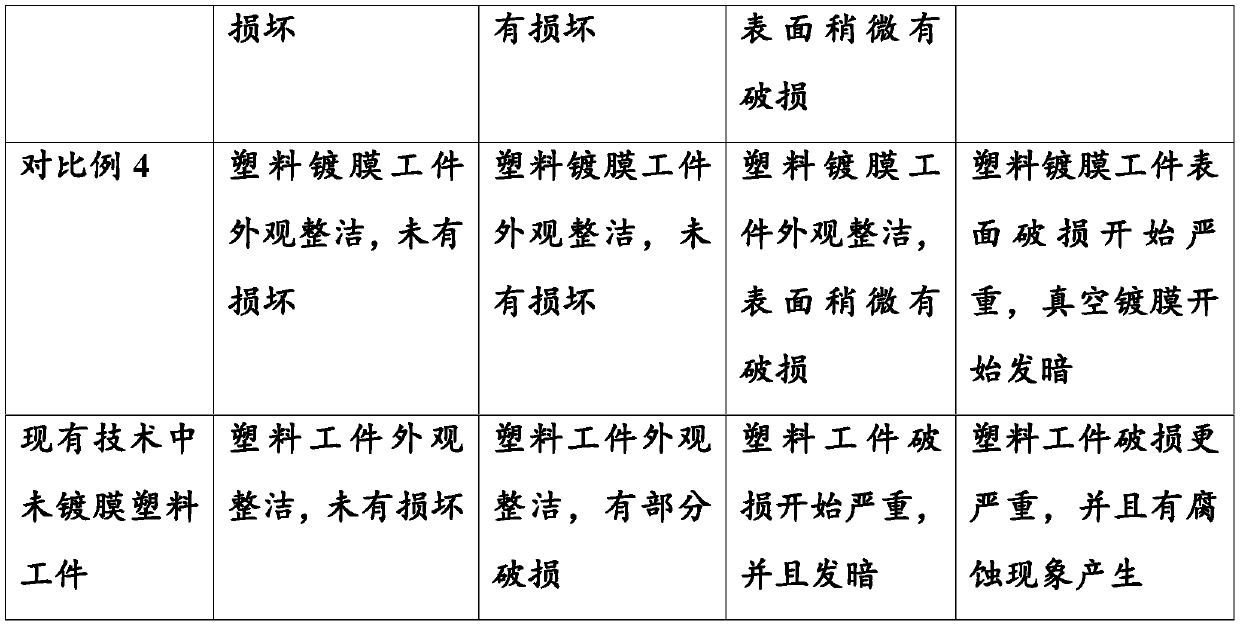

Examples

Embodiment 1

[0055] 1) Put the plastic workpiece on the workpiece rack, and the workpiece rack is transported to the primer coating and curing room under the action of the conveying base. Keep the temperature of the primer spraying chamber at 10°C and the humidity at 30%, and spray the UV primer On the workpiece, and during the spraying process, the workpiece frame rotates at a speed of 5 Hz during the UV primer spraying process; then solidify for 5 minutes to form a UV primer film layer on the surface of the workpiece, and the thickness of the UV primer film layer is 5 μm. Obtain a workpiece with a UV primer film;

[0056] 2) Then the workpiece with the UV primer film is transported to the vacuum coating studio under the action of the conveying base, and after the workpiece is plasma cleaned; the heating temperature of the Al evaporation source is controlled to 100°C, and the melting 10s, then at 1000℃, 10 -2 ~10 -3 Vacuum coating is carried out under Pa, so that it evaporates into a ga...

Embodiment 2

[0059] 1) Place the plastic workpiece on the workpiece rack, and the workpiece rack is transported to the primer coating and curing room under the action of the conveying base. Keep the temperature of the primer spraying chamber at 20°C and the humidity at 50%, and spray the UV primer On the workpiece, and during the spraying process, the workpiece frame rotates at a speed of 15Hz during the spraying process of the UV primer; Obtain a workpiece with a UV primer film;

[0060] 2) Then the workpiece with the UV primer film is transported to the vacuum coating studio under the action of the conveying base, and after the workpiece is plasma cleaned; the heating temperature of the Cu evaporation source is first controlled to 200 ° C, and the melting 15s, then at 800℃, 10 -2 ~10 -3 Vacuum coating is carried out under Pa to make it evaporate into a gas molecule state and adhere to the surface of the workpiece. During the vacuum coating process, the workpiece frame rotates at a spee...

Embodiment 3

[0063] 1) Place the plastic workpiece on the workpiece rack, and the workpiece rack is transported to the primer coating and curing room under the action of the conveying base. Keep the temperature of the primer spraying chamber at 35°C and the humidity at 80%, and spray the UV primer On the workpiece, and during the spraying process, the workpiece frame rotates at a speed of 18Hz during the UV primer spraying process; then solidify for 30min to form a UV primer film layer on the surface of the workpiece, and the thickness of the UV primer film layer is 25 μm. Obtain a workpiece with a UV primer film;

[0064] 2) Then the workpiece with the UV primer film is transported to the vacuum coating studio under the action of the conveying base, and after the workpiece is plasma cleaned; the heating temperature of the Ni evaporation source is controlled to 300° C., and the melting 20s, then at 500℃, 10 -2 ~10 -3 Vacuum coating is carried out under Pa, so that it evaporates into a ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com