Interior structural linings for vehicle side doors and side doors so equipped

A lining, side door technology, applied in the direction of vehicle components, transportation and packaging, doors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

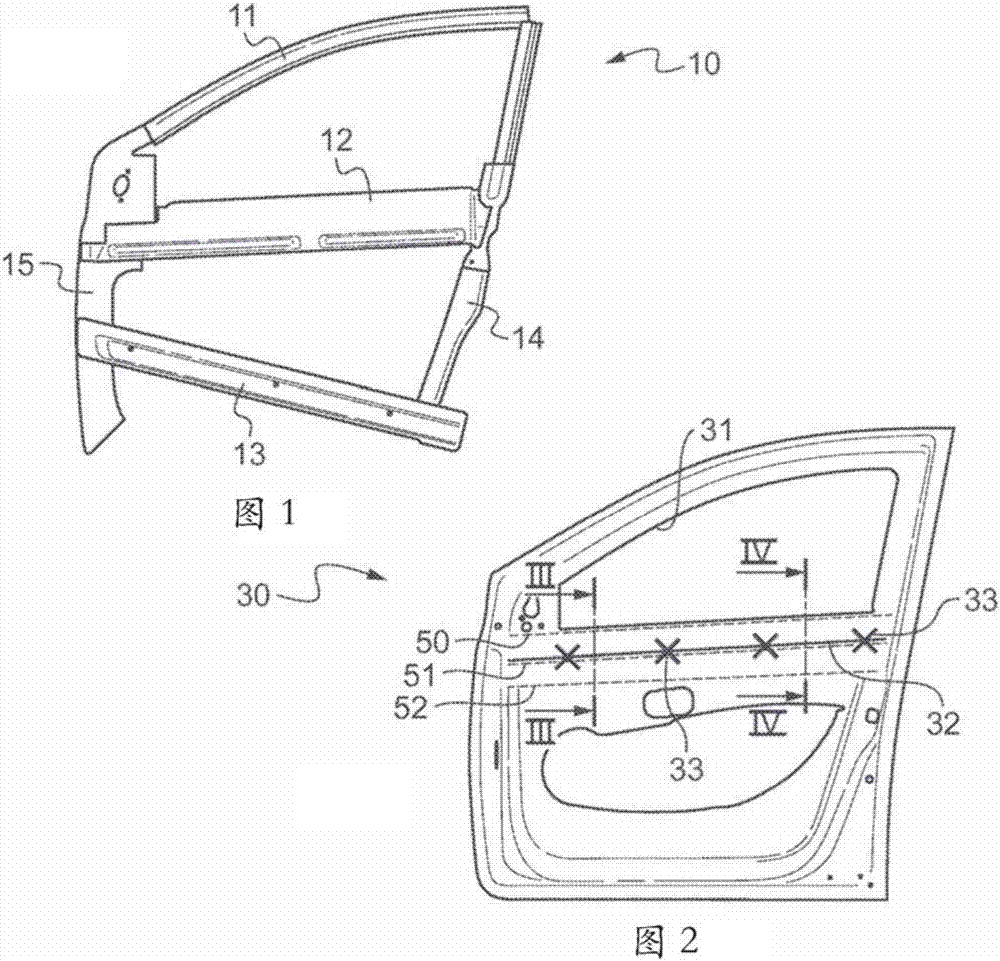

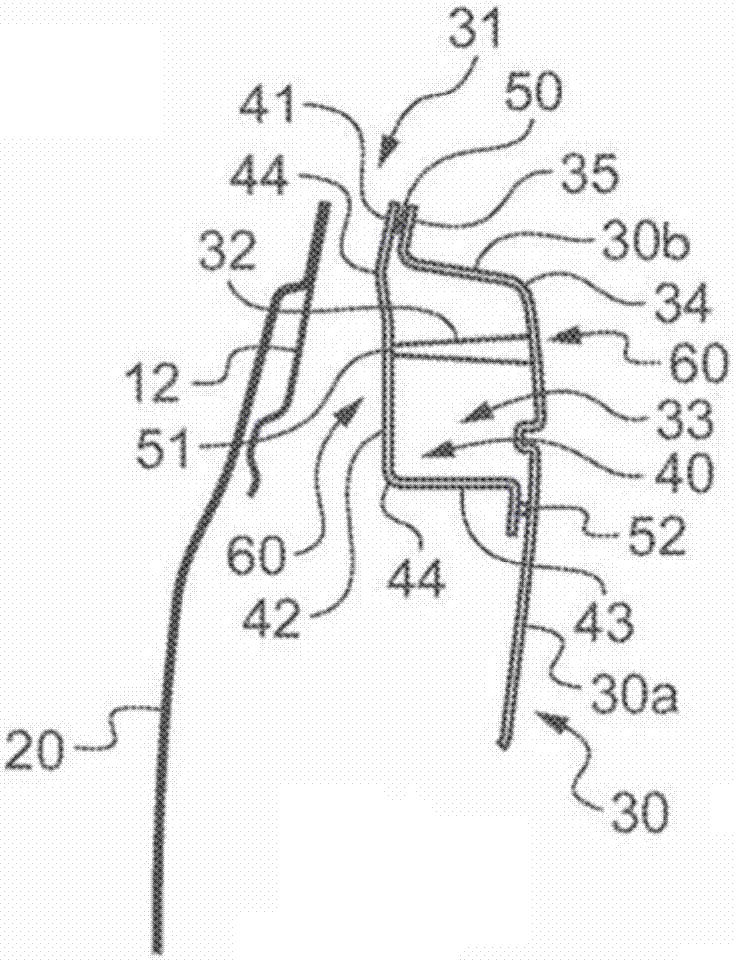

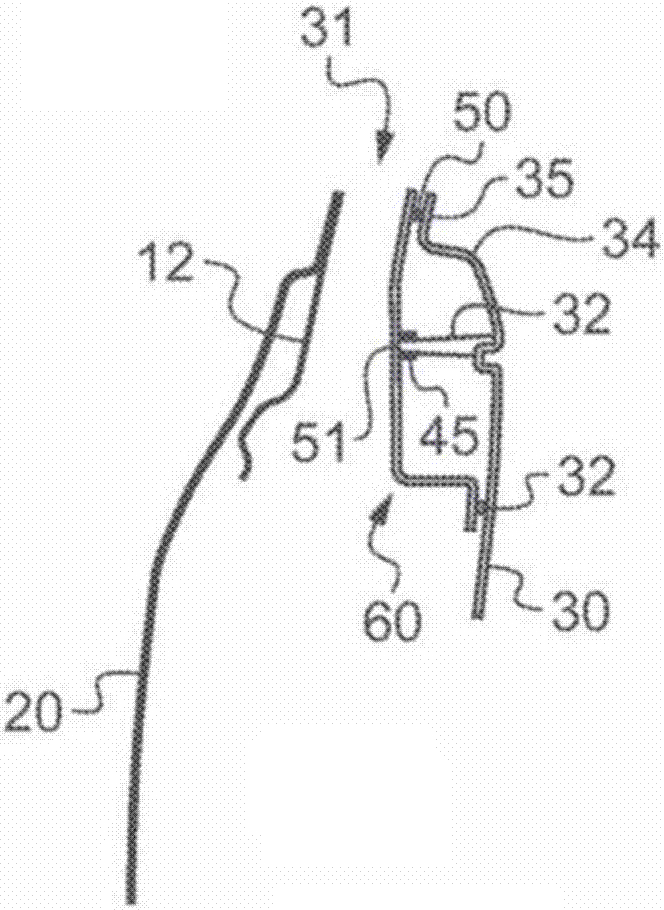

[0028] figure 1 Shown is an aluminum side door frame 10 comprising a frame reinforcement 11 defining a window opening, a waistline reinforcement 12 defining a molding area below the window opening, an angled intrusion reinforcement 13, A reinforcement 14 of the rear part of the housing and a reinforcement 15 of the front part of the housing, all of which are made of aluminum or any other strong but relatively lightweight material. The aluminum frame 10 is designed to receive an outer skin 20 of the side door on the outside of the vehicle and an inner lining of the side door 30 on the inside ( image 3 ).

[0029] The outer skin 20 is divided into several parts: an upper part following the upper part of the door frame 11 around the window opening, and a lower part forming an outer panel covering the bottom of the door below the window opening, in image 3 and Figure 4 This lower portion is shown secured to the waistline reinforcement 12 in .

[0030] The inner liner 30 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com