Infrared heating device and drying furnace

A heating device and infrared technology, applied in the direction of heating to dry solid materials, electric heating devices, heating element materials, etc., can solve the problems of overheating, peeling off of the reflective film, deterioration of the reflective film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

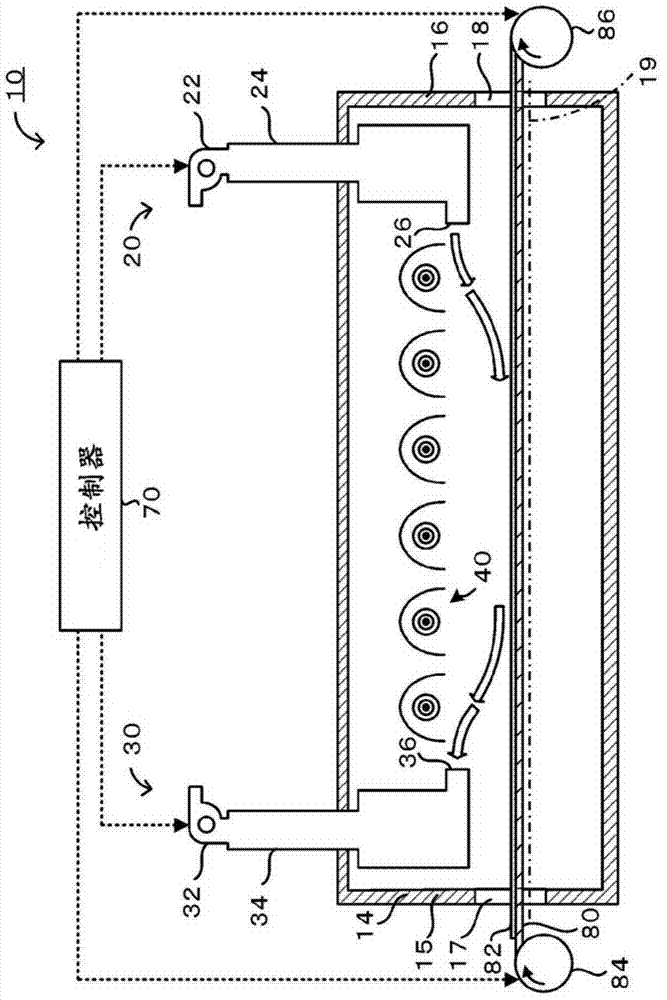

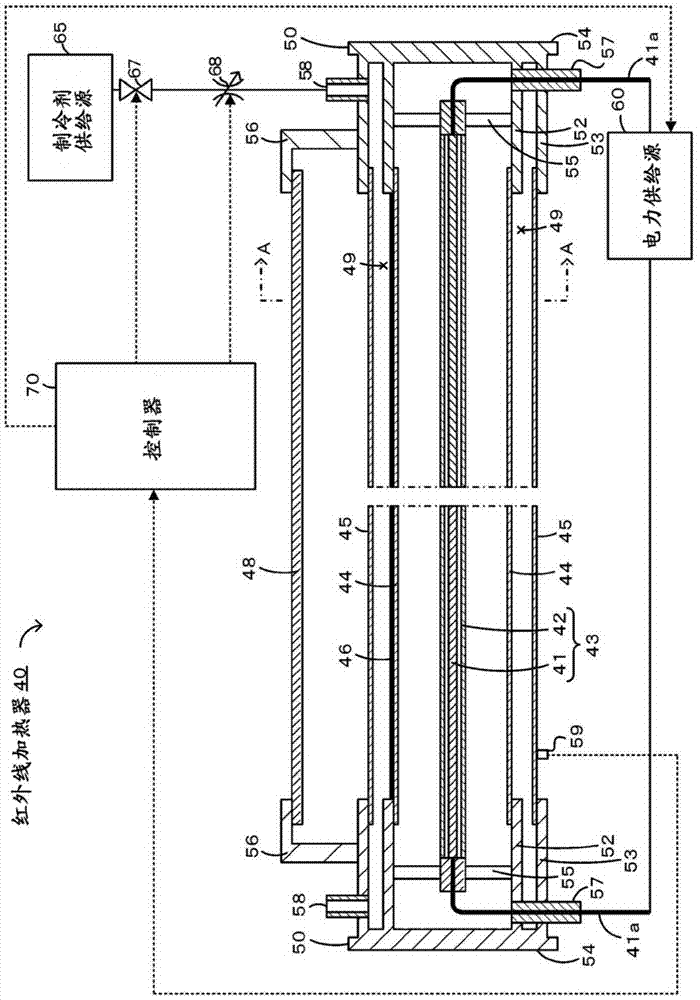

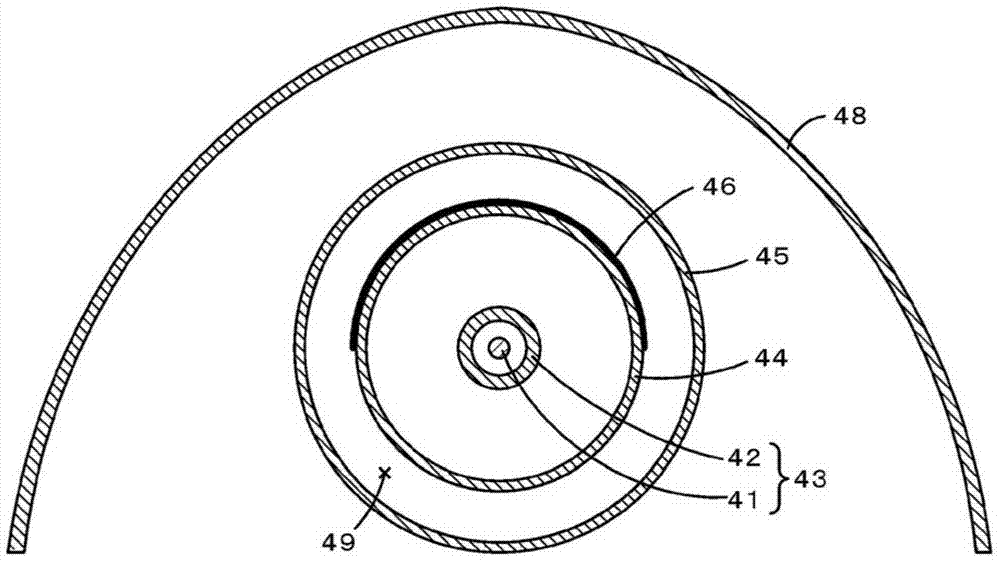

[0064] by Figure 1~3 The infrared heater 40 of the shown structure is Example 1. FIG. In addition, the outer diameter of the filament 41 of the heater main body 43 is 2mm, the material is tungsten, the heating length is 600mm, the material of the inner tube 42, the first outer tube 44, and the second outer tube 45 is quartz glass, and the material of the reflective layer 46 It is gold, and the film thickness is 5 μm. The reflector 48 is made of SUS304.

Embodiment 2

[0066] as Figure 8 As shown, except that the reflective layer 46 is not formed on the outer surface of the first outer tube 44 but is formed on the outer surface of the second outer tube 45 and the reflective layer 46 covers the upper half of the second outer tube 45 , the infrared heater having the same configuration as the infrared heater 40 of the first embodiment is the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com