Water tank structure of electric steam box

A technology of electric steamer and water tank, which is applied in the direction of steam cooking utensils, cooking utensils, household utensils, etc. It can solve the problems of easy aging of sealing rings, hidden dangers of water leakage, and unreliable sealing, so as to avoid poor sealing and easy aging of sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

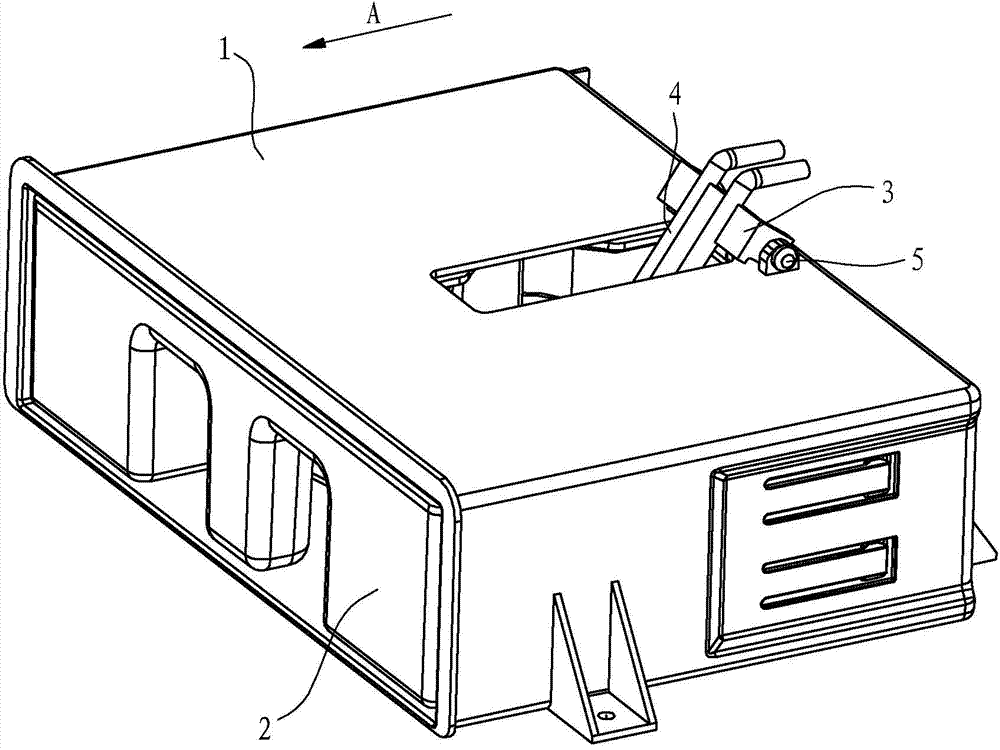

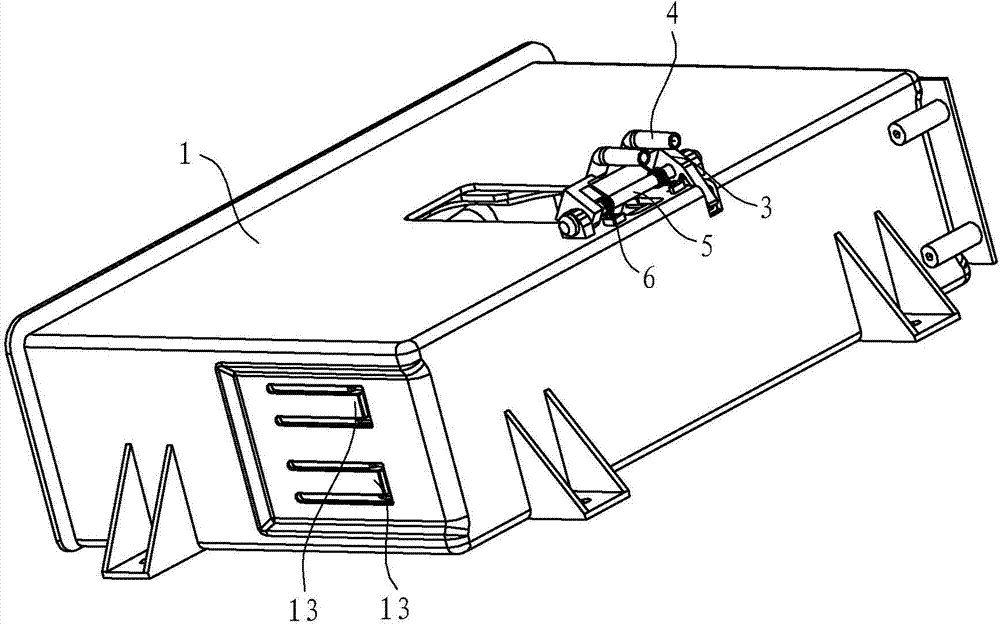

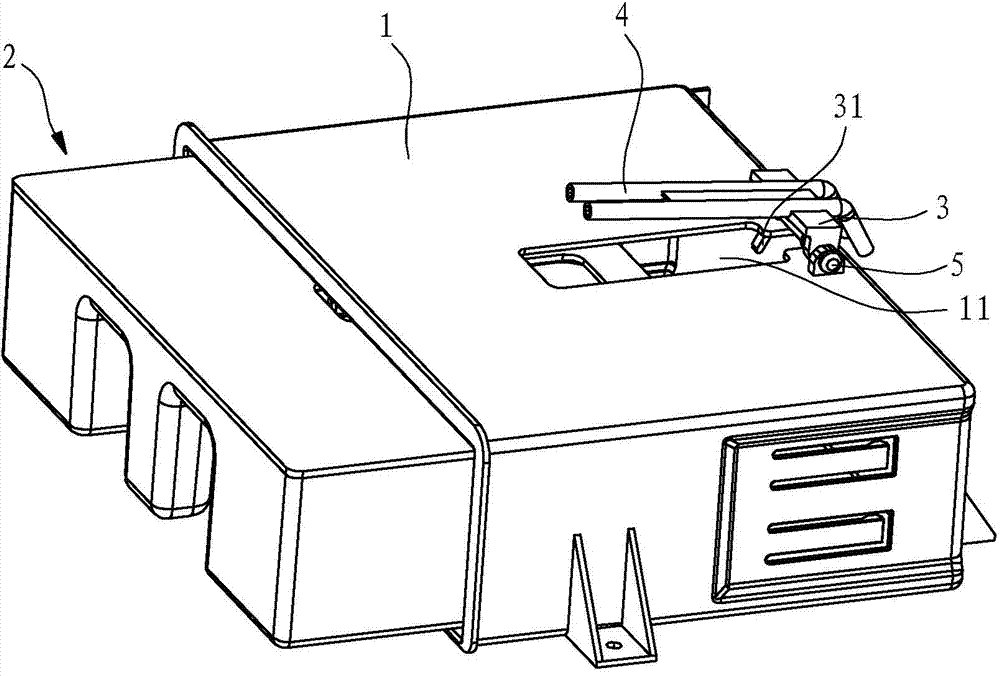

[0025] like Figure 1 to Figure 7 shown in figure 1 The direction indicated by the arrow A is forward. The water tank structure of the electric steamer in this embodiment includes a water tank support 1 and a water tank 2 mated with the water tank support. A fixed shaft 5 is installed above the rear side of the water tank support 1. On the fixed shaft 5, a swivel bracket 3 capable of rotating forward and backward is installed. The bottom of the swivel bracket 3 has a swing arm 31 extending forward and downward and capable of colliding with the back of the water tank and rotating. The swing arm 31 is integrated with the swivel bracket , the rear end of the water inlet and outlet pipe 4 is installed on the rotating bracket 3, and the water inlet and outlet pipe 4 is located above the swing arm 31 and rotates synchronously with the swing arm 31, and a torsion spring 6 is installed on the fixed shaft 5, and the torsion spring 6 One end of the torsion spring is fixed on the rotati...

Embodiment 2

[0034] like Figure 8 As shown, the water tank structure in this embodiment adopts an electric control method to rotate the water inlet and outlet pipes 4. Specifically, a micro switch 7 and an electric push rod 8 are installed on the water tank support 1, and the controller 9 is used to drive The electric push rod 8 stretches out or retracts, and the torsion spring is used to reset the rotated water inlet and outlet pipes 4 to the initial position.

[0035] The working principle of the water tank structure in this embodiment is as follows: when the water tank 2 is pushed into the water tank support 1, it is closed when the micro switch 7 is touched, which indicates that the water tank 2 has been pushed into place, and the controller 9 receives the signal and sends out The signal drives the electric push rod 8, so that the electric push rod 8 stretches out and the water inlet and outlet pipes 4 rotate counterclockwise, and the rotated water inlet and outlet pipes 4 extend into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com