Prefabricated outer wall embedded with triangular overhanging mounting structure and manufacturing and mounting methods thereof

A technology of installation structure and manufacturing method, which is applied in the direction of manufacturing tools, building structure, building structure support, etc., can solve the problem that the outer leaf plate cannot meet the bearing capacity of the triangular cantilever, the outer leaf plate increases the repair workload, and there are quality risks and other problems to achieve the effect of avoiding hidden dangers of water leakage, saving manufacturing costs, and avoiding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

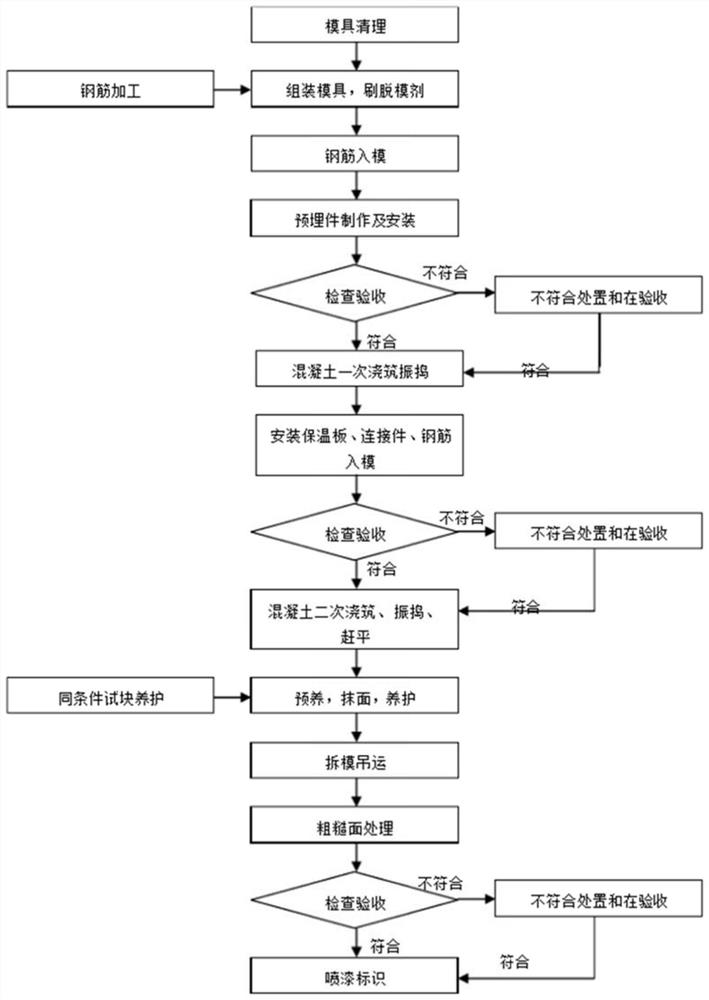

[0038] Such as figure 1 Shown is a flow chart of the method for manufacturing the prefabricated exterior wall provided in a preferred embodiment of the present invention.

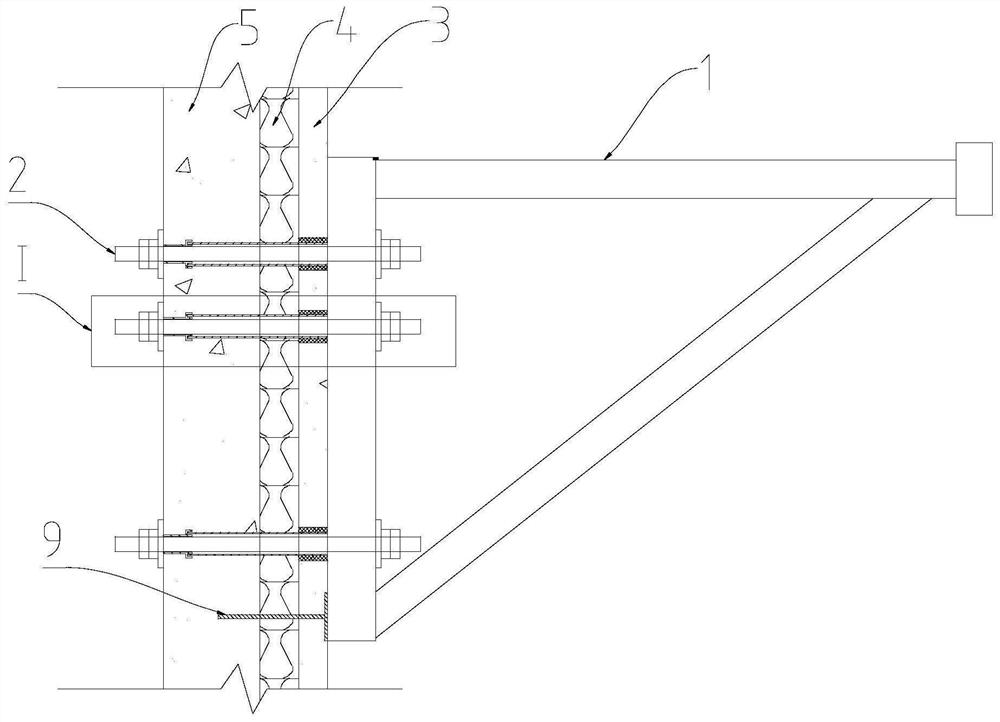

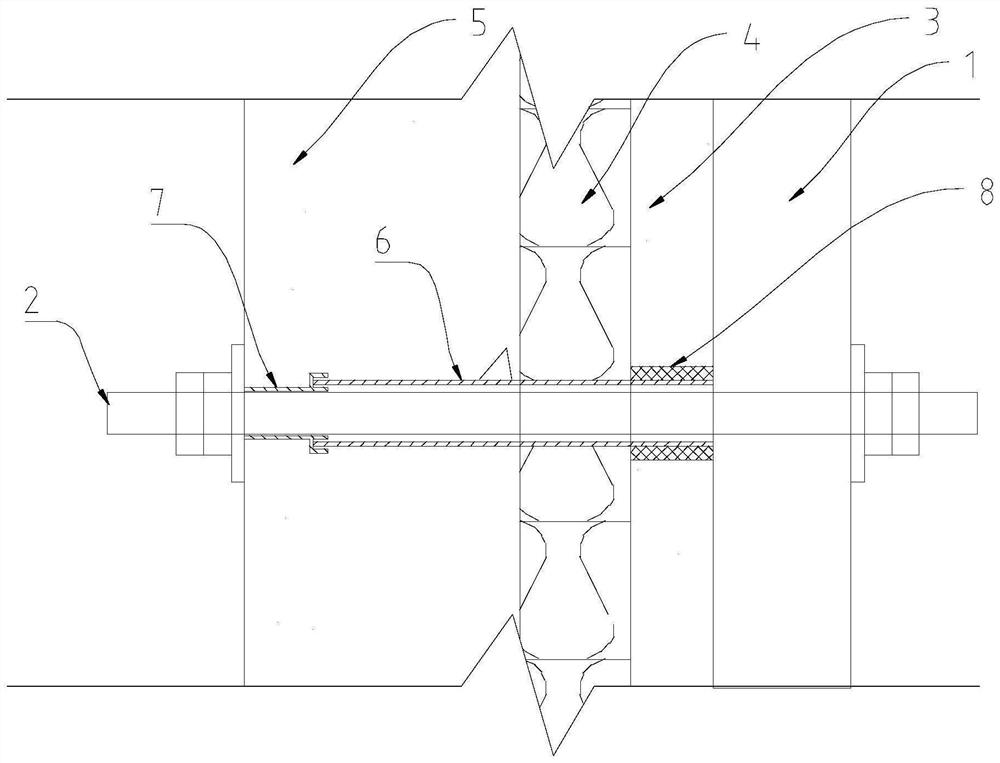

[0039] Such as figure 2 As shown, the use form of the prefabricated exterior wall that the present invention needs to manufacture has a built-in triangular cantilever installation structure in the wall, which is used to install the triangular support frame 1 on the prefabricated exterior wall, and can be used without removing the heat preservation The plate and the outer leaf plate meet the bearing requirements of the triangular support frame 1 through the form of embedded parts in the wall. The manufacturing method of the present invention is just used to prefabricate the prefabricated exterior wall in a factory, and it can be directly transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com