Rotary valve pulser capable of sliding underground

A pulser and rotary valve technology, which is used in wellbore/well components, measurement, earth-moving drilling, etc., can solve the problems of complex and easily damaged telescopic rod structure, high cost of wet joints, and easy occurrence of water leakage, etc. The effect of shortening instrument length and reducing battery usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

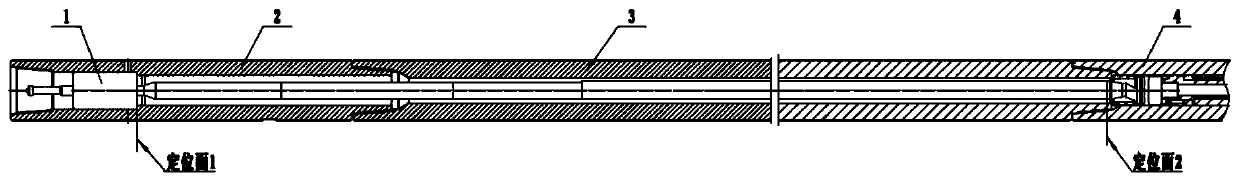

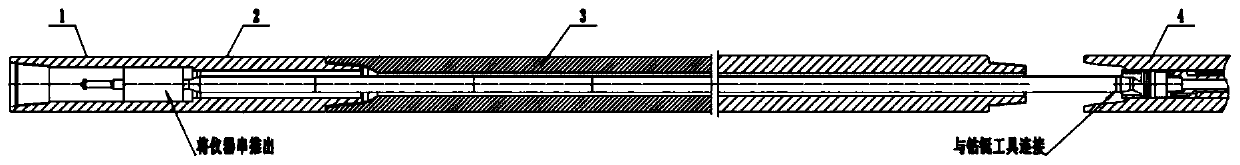

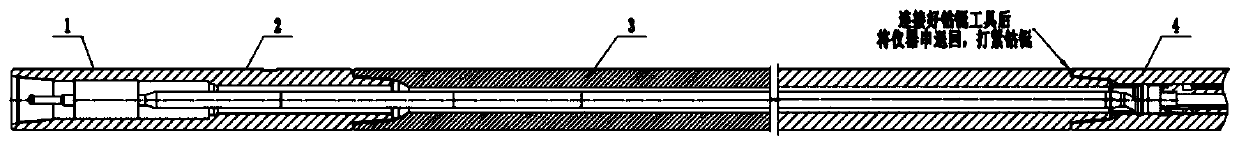

[0020] Embodiment one: Figure 1-Figure 4 A downhole slidable rotary valve pulsator is shown, the downhole slidable rotary valve pulsator is mainly composed of: rotary valve pulsator instrument string 1, suspension drill collar 2, non-magnetic drill collar 3, drill collar tool 4, The suspension drill collar 2 is connected to the non-magnetic drill collar 3, one end of the rotary valve pulser instrument string 1 is placed inside the suspension drill collar 2 and the non-magnetic drill collar 3, and the rotary valve The other end of the pulser instrument string 1 is rigidly connected to the drill collar tool, and the rotary valve pulser instrument string is rigidly connected to the drill collar tool, which is stronger than the existing connection method; one end of the suspended drill collar 2 It is connected with the non-magnetic drill collar 3, and the other end of the suspended drill collar 2 is provided with a movable chamber inside. Since the pulser can move in the drill co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com